Multi-diagonal planking is essentially the same as cold-molded. Multi-diagonal planking is used when the hull incorporates compound shapes that cannot be formed with sheet plywood. Often, this only occurs in the forward section on the bottom or the bottom and sides, but some hulls may require the method for the entire hull. This method is also referred to double diagonal or triple diagonal, depending on the number of laminations required. The starting point for the following photos is the same as described for sheet plywood planking.

The builder is shown fitting the initial layer of a diagonal planking bottom. While the initial strips can be applied at any convenient point, this builder has begun at the bow. Notice how the pieces fan out. The strips are laid in place and shifted until they lay flat, then fitted to the previous piece. Each planking strip must be edge fitted to the preceeding one for a tight joint. It makes little difference whether the edges of the pieces are parrallel or more triangular in shape as long as they make the bend and contact hull members.

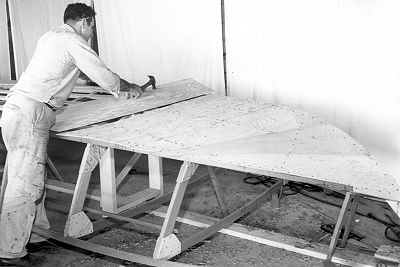

As the flatter areas of the hull are reached, less edge fitting is required and the size of the planking pieces can be increased as much as the form of the hull will allow. Notice that with this planking method, fastenings are driven into all hull members, even the athwarship frames. This differs from sheet plywood planking that is fastened only to longitudinals, stem, and transom. NEXT