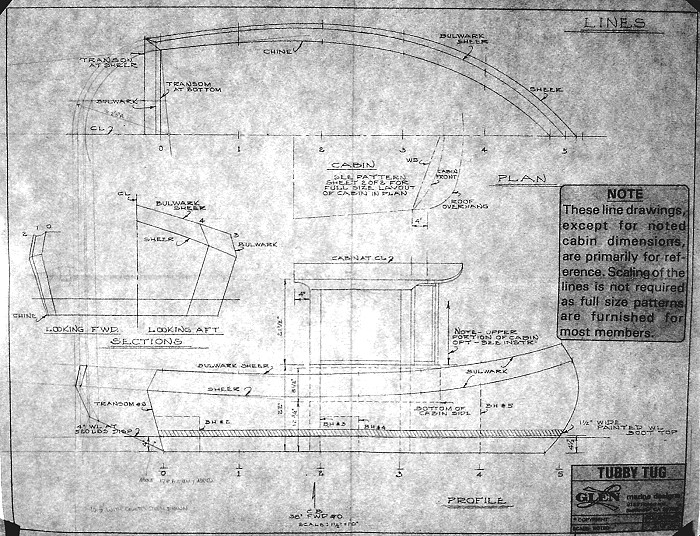

Tubby Tug by Bill Hodgdon, Strafford, New Hampshire

June 25, 2009This recently completed project (Launched Aug 1, 2008) involves a modified Tubby Tug, which is different from the standard version in that it is electric power, has a folding top, and a fantail stern.

I have built about a dozen boats, the first being a Glen-L Squirt in 1960 with my Dad. I was also a draftsman and later an engineer before I retired. I only point this out because the faintail stern modification I did, involved complex full-size lofting that I do not recommend to anyone without the experience to do so (not recommended for new boatbuilders). That said...here's my story.

My wife wanted a small electric boat to go out on the lake early in the morning as the sun rose, to watch the Loons, and just quietly look at the peaceful morning. When she asked me to build her one, I took her to the Glen-L site and asked her which of the special purpose electric boats she wanted me to build. Unexpectedly, the Tubby tug was also in that category, and she said for sure, that was the one she wanted. Unfortunately, we have a low bridge (42" clearance), so the top would need to be retractable, somehow (leaving the top off was not an option). My 88 year old Dad spent lots of time helping aboard the local harbor tugs as boy, and we both thought that even though it would make the job much more difficult, the transom should be a traditional fantail stern. (I think I spent as much time on the fantail stern as on the rest of the boat, all considered). Since there are many excellent articles on building the Tubby Tug, I will just focus on these different modified areas of my Wife's Tubby Tug.

A sketch on the study plans showed that the fantail stern was

possible, and would not look unreasonable, so I proceeded to

design a new stern for the Tubby Tug. This was done full-size

on some of the plywood that would become the hull (and so

there are no remaining plans for the design change). A quick

check of moments showed that the two AGM batteries mounted at

the front seat area would effectively offset the approximate

weight of the new stern, taking into account the minor

increase in displacement. The fantail was developed to be

circular from directly overhead, with the hull sides and

bulwarks being conical. Note that the circular appearing

rings used to form the fantail are actually not exactly

circular, since they are not in the horizontal plane. There

is nothing truly circular in any of the framework for the

transom.

So, the first set of parts were cut out from the plans and

the lofting. The hull sides were scarf joined in lieu of

using a butt block. It wasn't until after I took this

picture that I realized I had made a little space man out of

the parts...totally by accident. You can see many of the

parts that form the fantail stern in this shot.

Here we have begun construction. The inclined bottom of the

fantail stern begins where the true transom should be

located. The rear seat supports are angled slightly to

provide a better drainage to the center of the rear seat

area, where a bilge pump will be located. (Length and side

angle requires adjustment with this change). The rectangular

center well for the trolling motor has a vertical forward

face to allow retraction of the trolling motor for trailering

or beaching. The motor and propeller will completely retract

above the bottom of the boat. The front seat has been cut

down for a cushioned swivel chair, and the forward front seat

support has been moved forward to allow room for the AGM

batteries to sit in a fore and aft orientation. This requires

changing the forward seat supports to fit the hull in the new

location. The front seat will swivel 360 degrees when

installed, making it easy to get in the pilot house.

The lower ring has been attached to the normal Tubby Tug

modified transom and will define the joint location between

the hull and bulwark. The normal transom portions are

actually angled back per plan, although they do look vertical

here.

Here's another view for reference. The two stiffeners

attached to the bottom are temporary.

Here is one-half of the fantail hull panel (they are butt

block joined on centerline). The 5-ply 1/4" plywood was

too stiff to bend around the curve without breaking, so 1/8:

cuts were made approx 3/4" apart along the panel. Note

that since this is a conical panel, the cuts are not

parallel. (After installation, the grooves were filled with

epoxy paste and then the panel was epoxy fiberglassed over.)

Here is the panel, clamped in place for a trial fit.

The fantail stern hull panels are installed and the ring that

defines the top of the fantail bulwarks has been installed.

You can see the white outlet for the bilge pump in this view.

The hull panel overlaps the bottom here, and it has not been

trimmed yet.

Now we have installed the fantail bulwarks as well. These

panels also required relief cuts to prevent breakage.

Well, now it's beginning to look like a fantail stern!

This is a trial fitting of the cabin, note the cut off posts

where gussets will be added for the cabin top pivots. The

posts are all aligned fore and aft, not aligned with the

cabin sides. Tapered shims were used for proper alignment.

This is so there will be no binding when the roof pivots

down.