Epoxy Resins

Your exclusive source for

POXY-SHIELD®

Epoxy boatbuilding resins.....

Poxy-Shield epoxy

resin

Poxy-Shield prices

Poxy-Grip adhesive

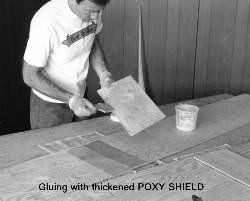

There are many types of epoxy, designed for a myriad of applications. POXY-SHIELD® was designed specifically to meet the needs of boatbuilders. POXY-SHIELD® is used for coating (encapsulating), gluing, making fillet putties, and fiberglassing. POXY-SHIELD® seals out moisture, reduces maintenance, and increases resale value. As discussed in WoodenBoat and other magazines, epoxy is the resin for use on wooden boats.

POXY-SHIELD® is used for gluing, coating, encapsulating, fairing, and fiberglassing. It is virtually indispensable in Stitch and Glue construction. This clear, pale amber, low-viscosity resin (used with one of the hardeners below) forms a surface that is clear, tough, and mar-resistant. The resin requires no costly thinners, and includes no hazardous diluents such as BGE. For those builders choosing not to use the encapsulation system, POXY-SHIELD® is still the resin used for fiberglass application and is our most popular glue, used with or without the addition of fillers, depending on the application.

When using as a glue, for making Stitch and Glue fillets, or for use as a fairing compound, add one or a combination of our FILLERS. This versatility means that only one resin is required for all aspects of your boatbuilding project. There is no need to buy a variety of costly pre-mixed products - you make what you need. Use on all types of woods, most metals, and some plastics. The 100% solids formulation is waterproof upon curing and does not shrink. Heavy clamping pressure is not required, and when mixed with one of the fillers, has gap-filling properties so that precise joints are unnecessary.

POXY-SHIELD coverage:

How much POXY-SHIELD® for Encapsulation |

POXY-SHIELD® Resin is mixed with POXY-SHIELD® Hardeners at a 5:1 ratio (five parts resin to one part hardener by volume or weight). Our graduated mixing containers make this easy.

PART B - POXY-SHIELD® HARDENERS

Use FAST Hardener when quick curing is necessary or for use in lower

temperatures (down to about 40o F is possible, although cure time

increases as temperature decreases). Use SLOW Hardener where longer cure time

is required or in warmer temperatures. SLOW Hardener is recommended for

fiberglass sheathing (although at temperatures below 65o F the resin

is harder to wet out).

IMPORTANT NOTE: Hardeners can be mixed together allowing the builder to

vary cure time and pot life to better suit the application, as long as the 5 to

1 resin/hardener ratio is maintained.

For further information, please see the EPOXY TECHNICAL MANUAL.

NOTE: Pot life cannot be accurately stated without

setting parameters. Heat is the factor that controls cure time, but heat is

affected by the volume of resin mixed and the shape of the container. If 8 oz.

of resin/hardener is mixed in a wide mouth container at 70o F, the

following cure times can be used for comparing the fast and slow

hardeners.

FAST HARDENER: Pot life is approx. 10 to 15 minutes, with partial cure in

about 5 to 6 hours.

SLOW HARDENER: Pot life is approx. 25 to 30 minutes, with partial cure in

approx. 6 to 8 hours.

POXY-GRIP®

EPOXY STRUCTURAL ADHESIVEThis superior waterproof marine glue is formulated specifically for the boatbuilder, whether amateur or professional. POXY-GRIP® is easy to use, requiring equal parts of resin and hardener (1:1 ratio). Use on all types of wood, most metals, and some plastics. It is completely compatible with the GLEN-L Epoxy Encapsulation System.

POXY-GRIP® cures below 40o F (although more slowly), and is suitable for high humidity or on woods with relatively high moisture content since it does not absorb moisture during cure. The resin component is nearly water clear, while the polyamide hardener is amber color. Cured joints are clear, becoming virtually invisible. Ideal for use under clear finishes.

Bond strength remains high even when bridging reasonable gaps. Heavy clamping pressure and fillers are not required. Just hold the mating parts stationary until cure takes place. The product does not run. Pot life, in a container with a large surface area, is about 30 - 40 minutes at 70o F. Partial cure in 6 to 8 hours, full strength in about 24 hours at 70o F.

POXY-GRIP is also ideal for automotive, aircraft, and hobby use and is free of noxious odors. A Quart Kit should be adequate for small dinghies or boats to about 10'. A Half-gallon Kit should be enough for boats in the 12' - 14' range. A Gallon Kit should suffice for boats to about 18'.