APPLICATIONS: Making fillets

A fillet is a radiused bead at the inside corner of parts joined at approximately right angles, or 90oF to each other. Fillets are commonly applied where plywood parts join, such as where bulkheads mate to the hull, or where cockpit soles mate to bulkheads, interior joinery work, etc. Parts can be bonded with fillets on one or both sides. However, if joints are not backed up with solid wood blocking or framing, or otherwise fastened to structural members, a fillet should be used on both sides for adequate strength.

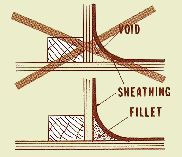

A fillet is also used to form the necessary inside corner radius when surfaces will later be covered with fiberglass or other sheathing. This prevents air entrapment (bubbles) that would form in the corner if the fillet did not exist. Since the sheathing material will tend not to conform to hard 90o corners, it will tend to lift from the surface in these areas.

A fillet increases the bonding area at the joint and strengthens it. The fillet material is simply a mixture of activated POXY-SHIELD® and one or more of our filler materials, such as Fibers, Microspheres and/or Silica. Two types of fillets can be made, either high-density or low density. The high-density fillet features a smaller radius using Silica as the filler material. The low-density fillet has a larger radius using a combination of Microspheres and Silica as the filler material. The Silica portion makes the mixture smoother, easier to apply, and allows easier feathering or smoothing at the edges. The high-density Silica-mixed fillet material is stronger, but somewhat heavier than the Microspheres/Silica mix and more difficult to sand.

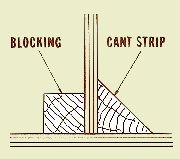

How big are fillets? As a recommendation, the larger the fillet, the stronger it will be, but of course, you use more material. As a structural joint (where no fastenings are used to hold the adjoining pieces and the pieces are of 1/4" to 1/2" thick plywood) we recommend a fillet with a radius of at least 3/4" when using the high-density mix. With low-density fillets, this radius should be about 1 3/4". When thicker plywood is used, joints are probably better being backed with framing or wood blocking, and fastened, or fitted with diagonally cut glue blocks (cant strips) in lieu of using fillets. This is because fillets of increasing size, weight, difficulty, and cost, would be required.

However, if the fillet is not primarily used for structural purposes (such as for sheathing applications), the radius is strictly what is required to work. With a lightweight fiberglass cloth, for example, a 3/4" radius of either a high-density or low-density fillet would be enough for the typical 6 oz. to 7 1/2 oz. weight to conform to. But, for a nicer appearance and better durability, such as where cabin sides join to decks, a larger radius will probably look better and be more durable. We prefer the low-density fillet using a 50/50 mix of Microspheres and Silica for most applications.

How thick should the filler mixture be? Basically, thick enough to do the job, but a consistency of peanut butter seems to work well. Although the exact proportions of fillers used can vary with temperature (warmer temperature = "runnier" mixture), type of filler materials added and application. We have found that a ratio of 2 to 2 1/2 parts of filler mixture to 1 part of resin/hardner mix is about right. If you use cellulose or cotton fibers, start with a smaller proportion of filler (1 to 1 1/2 filler to 1 part resin/hardener) and add additional filler until desired consistency obtained. When mixing, resin and hardener should be mixed first, then add fillers. When you find the combination of fillers that best suit your needs we suggest that the filler combination be pre-mixed so it can be more easily measured and added to the epoxy.

Make a few fillets initially to get a feel for the process. Some practice is necessary to make nice, smooth fillets quickly, and much depends on the "right" consistency of the mix. All surfaces of joining pieces must be coated first with activated POXY-SHIELD® or the resin in the fillet mix will be drawn into the wood. lf pre-coating was done and allowed to cure, make sure the surfaces are lightly sanded before applying the fillet.

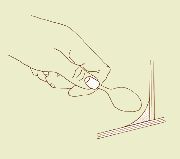

To apply fillets you will need various radii applicators that you can make yourself. Any round object can be used to form fillets, including tongue depressors, plastic lids, spoons, etc., but cutting your own from wood or flexible squeegees allows you to adapt the tool to the work rather than vice versa. Applications such as stitch and glue construction will require several different radii depending on the joining angles. Test tools prior to filleting by sliding them along joints to see that they give the radius you need at various junctions. To apply fillets, "glop" the filleting mixture in place then use your filleting tool to gradually spread the material and to pick up excess or add additional material.

Save yourself a lot of sanding by doing a good clean-up after applying fillets. Use a putty knife or comparable tool to remove ridges and other spots of excess fillet mixture. Once cured, the fillet can be sanded smooth. The area of the fillet should be covered with at least one coat of POXY-SHIELD®. If desired, however, this can be a subsequent part of the final encapsulating, coating or sheathing application.