APPLICATIONS: Sheathing with POXY-SHIELD®

We recommend that virtually all our wood boat design be covered or sheathed with fiberglass, especially plywood hulls planked with Douglas-fir plywood. While either polyester or epoxy can be used, the superior bond strength and flexibility of POXY-SHIELD® makes it the first choice. When using the GLEN-L Epoxy Encapsulation System, fiberglass cloth should always be applied with POXY-SHIELD® resin; polyester resins will not provide the qualities inherent in the GLEN-L Epoxy, and will not bond well to epoxy-coated surfaces. In lieu of fiberglass, there are other sheathing materials which are similarly applied. But since fiberglass is readily available, easily applied by the beginner, performs well, and is relatively economical, we prefer its use. Also, some materials other than fiberglass have problems associated with application and use which we feel make them not advisable for the beginner to use.

Fiberglass is applied for impact and abrasion resistance in order to protect the wood from the typical scrapes, dings, and bumps that the average hull is subjected to (especially the trailerable boat). In addition, the recommended fiberglass cloth acts as a screed to insure an even coating thickness, and prevents sanding away too much resin. The fiberglass covering also reinforces joints in the planking skin, helps cover defects, and adds extra insurance against insects and marine borers (teredos or "ship worms").

The fiberglass covering should be of cloth from 6 oz. to 10 oz., with the 7 1/2 oz. being a good compromise between light weight with ample protection. For durability, all exposed hull and deck surfaces should be covered, including cabin tops, cockpit soles, etc. Some builders prefer not to cover those areas which will be naturally finished, however, such a finish is still possible with fiberglass since the glass turns transparent when wetted out, especially when the lighter weight cloths are used.

Not all fiberglass cloths are alike or as suitable for use with epoxy resins as others. In the manufacturing process, the cloth must be treated or "finished" to remove impurities and assure that the resin will wet out the material. These finishes can vary, and hence some are more suitable with epoxy than others. The type of treatment that we use with our fiberglass cloth is a special proprietary finish that wets out easily and quickly with POXY-SHIELD® and forms an incredible bond to the wood structure. You cannot visually tell the difference in fiberglass cloth finishes by looking at them and even though the cloths may look the same, some commercial cloths are incompatible with epoxy.

We do not advise the use of fiberglass mat (chopped strand mat) with or without the use of cloth, primarily because there is no reason to use this material; it is heavy and requires much more resin in application. This drives up the cost and the weight, and the desired qualities can be imparted with the use of cloth alone. We also do not recommend woven rovings for similar reasons. In addition, not all mats are compatible with epoxy resins since the binders used in them are intended to be broken down by the styrene which is a part of all polyester resins, the type of resin usually used with mat. Our epoxy resins do not have this constituent and thus may not wet out all mats as readily.

lf extra fiberglass protection is desired, apply a second layer of cloth, although in our opinion a single layer is more than adequate for virtually all pleasure boats when POXY-SHIELD® is used. An exception to this would be when fiberglass materials are used to reinforce stitch and glue planking junctions. In this type of construction multiple layers of cloth or specialty double-biased cloths may be used in combination to reinforce epoxy fillets. Because this is not a "sheathing" procedure we will not go in to it here. For further information, you may wish to purchase the "GLEN-L STITCH-N-GLUE MANUAL", available from GLEN-L.

We recommend that sheathing be done at temperatures between 70oF and 85oF using only POXY-SHIELD®- Slow for ample working time. lf temperatures are slightly cooler, warm up the resin and hardener. To begin the sheathing application, all bare wood hull surfaces should have an initial coating of straight POXY-SHIELD® applied in the typical manner. After curing, any imperfections, dents, holes, etc., can be filled with a filler coat made with POXY-SHIELD® and Microspheres. An absolutely smooth finished surface at this point, however, is not necessary. Make sure the surface is clean, dry, and free of dust. Then the cloth can be applied, preferably using what we call the "dry method".

The "dry method" consists of cutting, fitting, and placing the cloth in position over the surface, then applying resin over the cloth. The other approach called the "wet method" consists of applying a coat of resin to the surface first, and then to apply the cloth over the wet resin. This latter method is not preferred since it is difficult to place the cloth and work the resin through completely before it begins to set up; the "dry method" is much easier. Cloth can be taped with masking tape, or tacked to hold it in position, removing fasteners before the resin sets up hard. If masking tape is used, allow the tape to cover no more than 1/8" of the cloth. This will make it much easier to remove.

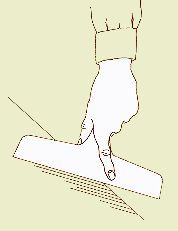

Using the "dry method", apply activated resin onto the cloth in a limited area and move it around with a roller, pressing down to force out trapped air. lf you are inexperienced with the use of fiberglass materials and the application tools, choose a smaller item or area, such as the transom, to get some training. Start the work in the center and work toward each end, using gloved hands and the roller to work out the wrinkles toward the ends.

The first coat of resin with the "dry method" is called the bond coat, and only enough resin as it takes to wet out the cloth and bond it to the hull is required. All areas must become transparent and free of entrapped air. Do not attempt to fill the weave of the cloth with this coat, or apply a thick, heavy layer, but do try to make the coat even without high and low areas (which will appear as dull and glossy spots), and free from sags and runs. Work the resin as long as possible with the roller to make this coat even. A properly applied sheathing at this point will have a matte finish with the weave visible. Don't allow any dry (white) spots and be sure to remove all entrapped air that builds up under the cloth as you go, prior to the resin starting to gel. (Note: Excess resin under the cloth may appear to be a bubble. This can be removed by repeated rolling to force out excess resin.) lf there is too much resin on the surface, remove the excess with a squeegee or similar tool and discard it. Trim excess cloth before the resin sets up hard, but not before the resin sets up a bit since you will drag and move the cloth otherwise. Make sure your mat knife is sharp and cut toward the surface. If you pull the cloth away from the surface at this point, it will not re-adhere and it may be necessary to patch this area.

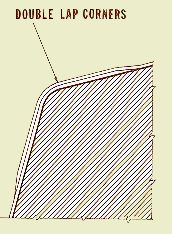

Joints in the cloth itself need not be lapped; they can be butted. However, at planking junctions such as along the keel, chine, transom corners, and similar situations, the cloth should be double lapped by several inches. After the resin sets up, such joints are preferably "feathered", with the first (underlying) layer of cloth tapered by sanding along the edge so that a ridge of excess cloth is not apparent.

After the bond coat is applied, again use activated POXY-SHIELD® for the second coat; this is called the fill coat and is used to fill and conceal the weave of the cloth. This coat is preferably applied with a roller. Other application tools will make an even coating more difficult to apply. There is no surface preparation necessary between coats, however, any runs, sags, or other uneven areas are preferably corrected (usually by sanding) before applying subsequent coats. Just take care not to sand through the cloth; if this occurs, such areas should be patched. Additional coats of resin can be applied after this, as required, to smooth out the surface and conceal the weave of the cloth, building up enough coating thickness for a sanding and finishing base. In most cases, three or four coats total should suffice. To augment the "feathering" of the second layer of cloth, you may wish to apply POXY-SHIELD®/Microspheres filler to "fair" out any remaining ridges. After a final sanding the hull can be finished.

For more information on fiberglassing see the book HOW TO FIBERGLASS BOATS, available from GLEN-L. (See Boatbuilding Books and Boatbuilding Videos pages)