Plywood Boatbuilding for Virgin Builders

by Dick Koepp

Continued

Based on my early experiences I would start a new boat by a "virgin" boat builder using the following guidelines:

BEFORE you obtain a set of plans for building a boat, consider the following:

- Boats take up space, sometimes a whole garage or two, or a barn or two. If you live in the cold winter areas, you need to consider how you will heat that space. Many glues and resins require 60+ degrees in order to effectively set up. How large will the boat be? (just in case you want to get it out of the garage later!).

- Most boats are built upside down using a building form. This means that at some point you will have to turn the hull over. How the heck is that done? I have developed several methods of turning hulls manually, which I will try and discuss in a later newsletter.

FINANCES

Make sure you can afford the initial outlay of money. It has been said that boats are holes in the water into which you pour money! My advice is to start small. Don't tackle a cabin cruiser for your first project. Also, read the Bill of Materials that will accompany your plans and building instructions. Then call the local lumberyards and see what materials will 'ball park' out at. Don't forget the fasteners, glue, brushes, resins, cloth, etc that will be needed. On the positive side, the best part of building your own boat is that you can control these costs, by selective shopping, and by stretching out purchases over time on an "as needed" basis. But beware, I have gone several ways with lumber and fasteners, and firmly believe that the building kits from the manufacturer are more economical over the long haul. Do not go cheap on lumber or fasteners. If you will need to buy new tools, you should include an estimate of those costs also. I buy my power tools from Sears mostly, and through the catalog. If you watch for sales, you can get some real bargains. (SEE "TOOLS" BELOW). Costs should be estimated for trailer, motor, cables, bait tanks, electronics etc.

Most boats need a trailer: Trailers can run from $500 to several thousand dollars, depending on your needs. Here, you might want to find used trailers, but honestly, used trailers unless, they are freshwater used only, are a bad bargain. Remember you will need manpower or jacks or whatever to place your boat on the trailer.

Most Boats need a motor: this is the most under estimated part of boat construction. You need to know what horsepower and shaft length you will be putting on the boat (outboards) in order to make the transom motor board the correct size. You need to know and estimate the steering system and control set up you are going to use. You will need to consider how to run wires and cables, water pipes below decks before you seal the bilges. I will talk about engine selection in a later newsletter.

Skill Level

Before you jump into a boat building project there are two important questions you need to answer:

- Do I possess the woodworking skills to complete the project?

- Do I have the proper tools with which to apply my skills and complete the project?

Don't worry about mistakes, half the fun in building is learning, and learning is making mistakes. When I built my first Playpen, I took a look at the bottom planking and the butt blocks that the plans called for amidships. I decided to make it easy on myself and shift the rear planks back 8" to allow the butt blocks to clear the center frame. BIG MISTAKE! I believe it was my ex-wife who pointed out to me the fact that the forward planks were going to be 8" short of the sheer and stem top; only problem was the rear ones were already glued and screwed. I learned a lot from that first Playpen. As a matter of fact, I believe it is still pictured in the Glen-L catalog (the picture without the man in the boat). Anyhow this leads to another factor in deciding to build a boat.

STUDY

Study the plans carefully, read books, talk to

other builders, use the builders web sites and email to them.  I get emails from many first time builders and enjoy trying

to help them out of questionable areas or terminology.

I get emails from many first time builders and enjoy trying

to help them out of questionable areas or terminology.

FAMILY considerations

IF you have no family, then you can skip this (or maybe not!) You must be aware of the narcotic effect of creating a boat. The hours slide by, and you are in your own world. If you are gainfully employed, then this will cramp the hours with the family even more. I encourage you to speak to your spouse about this project you have in mind. I would carefully prepare a list of pluses and minuses, with monetary impacts noted. Who will use the boat? Do you have children? Do they swim?

The style and features of the boat chosen to build is critical. My latest Glen-L design completed in July of 1998 is a boat called "Scooter". You can see it on the photos page at Glen-L site, or look it up in the catalog. This is NOT a boat for children. There are NO rails or gunnels. It is not designed for open water, rather it is a specialty boat for a specific geographic area, in this case, Tampa, Florida. The point is that you should carefully review what you want the boat to do for you. Fishing, skiing, scuba diving, long runs in open seas, shallows boating, etc. Then consider whether or not you need a cabin, below decks accoutrements i.e. head (toilet), bunks, kitchenette, dual controls etc. Again, think small initially.

How long will it take? It all depends on the size and the learning curve, not to mention the space and climate needs talked about above. I do NOT recommend moving a boat that is still on the building form until it is ready to be turned. Remember, you don't turn the hull until the bottom is completely finished including all fiberglassing, painting and lift strakes etc. The objective is to only move the hull once and that is when you turn it over. I built the Playpen on my first try in 6 months working weekends and nights on her. I worked full time the rest of the time. My second and third Playpens each took less and less time due to the fact that my tools were improving (meaning I got many essential power tools) and my skill level was improving (not to mention doing repetitive work). My third boat took 2 months to build and have on a trailer. It featured numerous improvements over the boat in the plans especially in the interior areas. I learned how to use bronze boat nails in fastening the planking to the hull timbers. Basically, I had no climate or space problems (by the way, don't build outdoors, it always rains), and I had no great need to rush, so I took my time. Learning something new can take longer for some than others.

TOOLS

Besides the basic hand tools, you will need TONS

of clamps, C-clamps, pipe clamps, you name it, get all you  can. You will need a

plane (portable power planes are preferable), at least one power belt

sander, a grinder, a series of saws, mainly power such as: jigsaw,

sawzall, band saw, circular saw, hole saw, back saw, chop saw (miter saw)

and table saw. Drills, bits, and hopefully two 12V+ portable power screw

drills. I have my own Delta 12" planer for sizing widths on rough

lumber. I have found several sources who supply me with oak and mahogany

in rough lengths and widths. Great savings can be made by shopping out

these types of economies. Flea markets, and garage sales can yield solid

tool bargains IF you know quality tools from cheap ones. I recommend

spending more for known quality.

can. You will need a

plane (portable power planes are preferable), at least one power belt

sander, a grinder, a series of saws, mainly power such as: jigsaw,

sawzall, band saw, circular saw, hole saw, back saw, chop saw (miter saw)

and table saw. Drills, bits, and hopefully two 12V+ portable power screw

drills. I have my own Delta 12" planer for sizing widths on rough

lumber. I have found several sources who supply me with oak and mahogany

in rough lengths and widths. Great savings can be made by shopping out

these types of economies. Flea markets, and garage sales can yield solid

tool bargains IF you know quality tools from cheap ones. I recommend

spending more for known quality.

CONCLUSION

Having considered all of the above, you are ready to choose a boat design that meets yours and your family's needs. Now, buy the plans, STUDY, STUDY, STUDY them. I know builders that actually build balsa wood models to see what is involved ..I don't recommend that myself, but whatever.

If you think out the issues above, and have a plan to deal with each, you can build a boat. If this is your first time, then be conservative. If money is an issue, again be conservative. Try a small boat. Finally, the whole idea from my perspective is to enjoy the process of boat building. You are creating something from nothing. Taking wood and shaping it into an object, a creation that will float in water. If you hit a snag, first call or email your boat's designer. I have had excellent luck with talking or emailing problems over the years to Glen-L's staff. They build many of their boats, and can answer any question you have. They want you to succeed, who knows, you might want to build that Klondike Cruising Yacht next!

Next time: Setting up and getting started.

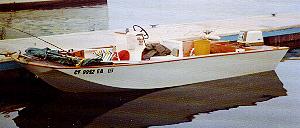

The boats pictured in this article were built by Mr. Koepp. The pictures were sent to Glen-L at time of construction. Boats shown, in order: Play Pen, built in CA; Escort, built in CA; Play Pen, built in FL. See Customer Photos/Archives for photos of Mr. Koepp's Scooter.

Back to Web Letter 7