Building the Zip

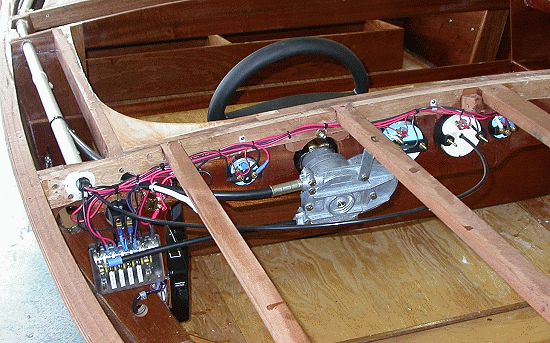

Now was the time to install wiring, gas tank, bilge pump, battery box, instruments , steering, and lights. The following two close ups give an idea of my set ups.

I used 3M 5200 Urethane adhesive to glue down the 4mm Okoume plywood sub deck.

The next step was to cut and install the king plank and covering boards. These were cut from 6 mm Sapele plywood. As mentioned earlier, they were covered with glass cloth and epoxy, primed with automotive primer and block sanded.

From an 8/4 x 12 inch mahogany plank, I cut the ¼ inch deck strips. After running one side through the planer, they finished at 3/16 inch. I alternated grain patterns for the layout. The sub deck was marked where the fasteners would be located. Several reference lines were drawn from stem to stern to keep strips in line. The strips were temporarily fastened with #6 hex headed sheet metal screws.

After the layout was complete, the screws were removed ( from one side at a time). Epoxy with a filler was spread over 100% of the sub deck and each strip re-installed with the same screws using a 1/8 inch spacer between strips.