Constructing a Curved Windshield (Cont'd)

by Stephen K. Yokubaitis

O nce the bottom of the windshield

has been traced onto the deck, holes are then drilled through

the deck and from these locations matching holes can be

drilled through the Lexan for the hold-downs. The hold-downs

can be easily bent to match the angle of the windshield at

each point.

With the windshield and vinyl channel held in place with the

hold-downs you can start fitting and cutting the front half

of the top windshield trim (gunwale molding). Holes are

drilled through this molding and countersunk, then the

molding is clamped onto the windshield along with the back

side molding (rub rail molding); securely hold in place with

as many clamps (and hands) as will fit.

You want the two moldings tight against the Lexan surfaces;

the front molding (gunwale) tight against the top edge of the

Lexan and the rear molding (rub rail) tight against the

overhang of the front molding. The front molding is then used

as a guide to locate the holes to be drilled "in

place" through the existing holes in the front molding

continuing through both the Lexan and the back molding. The

holes in the Lexan are later redrilled to 1/4" to

accommodate the vacuum hose grommets.

The vinyl channel also needs to be trimmed to suit. It is

best to trim the upper part of the channel around the

aluminum windshield trim but to leave the bottom of the vinyl

channel under the ends of the aluminum trim to protect the

deck.

My windshield measures approximately 15" at the

centerline of the boat by 92 1/2" along the top edge of

the windshield. It slopes approximately 37 degrees from

vertical at the boat's centerline to nearly vertical at

the outside ends of the windshield. At its base my windshield

is offset approximately 11" forward of the cockpit edge

at the boat's centerline.

Photos of Process

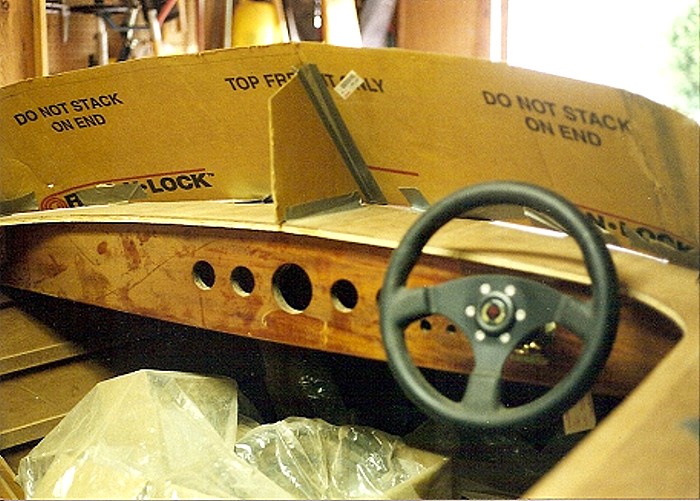

Cardboard template taped in-place. A light

weight solid cardboard would have been better suited for this

application but, a large corrugated box is what I happened to

have. The steering wheel is in place in this photo because it

was at this stage of construction that I was experimenting

with various seat heights relative to the steering wheel and

also working to determine the appropriate windshield height

to give an unobstructed view.

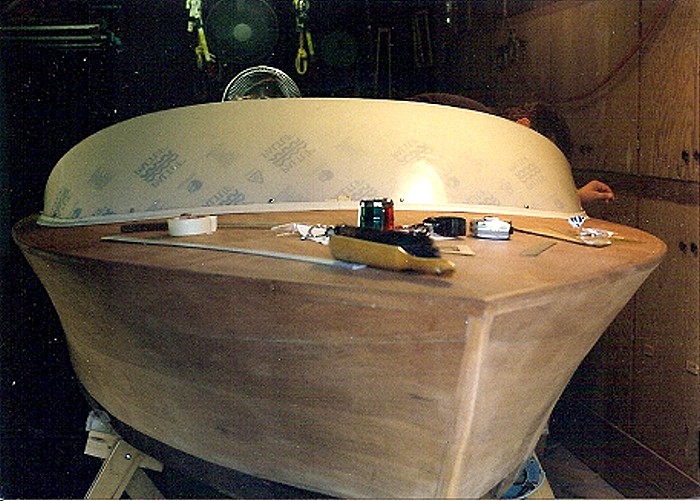

Cardboard template taped in-place. I used a scribe to mark a

fair line along the deck edge of the windshield

template.

Template clamped and weighted down ready to mark and cut

Lexan. I never did use my barbell set for its intended

purpose but have used the weights many times in applications

similar to this.

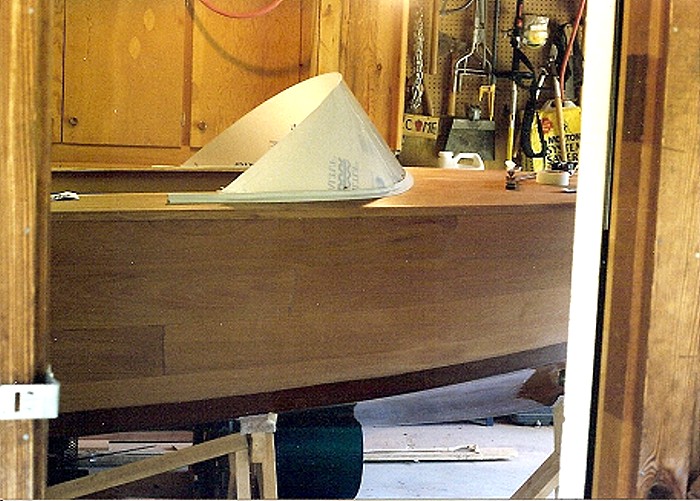

Windshield with protective film still attached. Hold downs

and deck channel are in place.

Note: Deck channel ends are not trimmed at this stage.

Windshield with protective film still attached. Hold downs

and deck channel are in place.

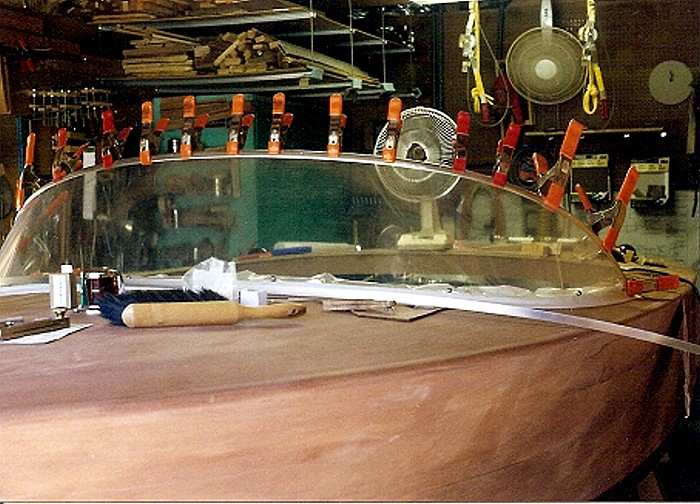

Fore trim (gunwale) clamped in place. Note: ¾"

aft trim (rub rail) has been bent to shape but is not in

place and is lying across deck in this photo. You can never

have too many clamps.

Side view of finished windshield with deck channel ends

trimmed. White protective film has fallen from the Lexan but

clear film is still trying to hold on. I left the protective

films on as long as possible.

Final view from front.

The finished boat, "Mistress."

Another view.