Rigging Small Sailboats

Chapter 8

.....outfitting spars

Page 2

|

|

8-3 |

|

|

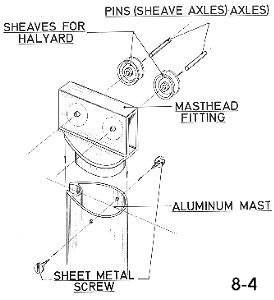

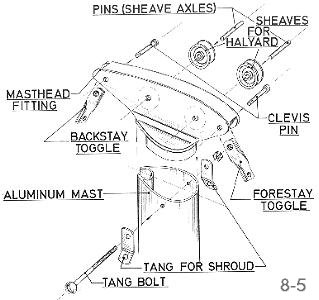

FIG. 8-2 through 8-5 - Masthead fittings used on aluminum masts. Figs. 8-2 and 8-3 are similar, but Fig. 8-2 shows the external halyard carried up one side and down the other utilizing two sheaves at the masthead. Fig. 8-4 shows the exploded assembly of Fig. 8-3, which uses the same halyard arrangement. Optionally, the halyard could be run internally through a hole in the fitting and using a fairlead at the mast base for the exit point. The halyard would then lead only over one sheave. This fitting is intended for cat or jibhead rigs as there are no provisions made for attaching the stays. For use with masthead rigs, something like Fig. 8-5 is used. The halyards run internally through a slot in the cap part of the fitting. The tang bolt may pass through the fitting or just below it, depending on the size of the fitting. |

|

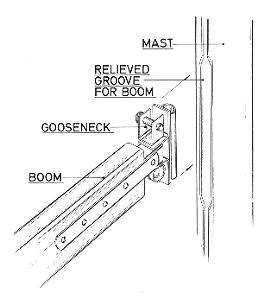

With aluminum spars, most of the other fittings, such as the masthead fitting, or boom gooseneck fittings are made up of aluminum castings which fit the spar extrusion (see Figs. 8-2, 8-3, 8-4, and 8-5). Once the lengths of the spars are known, these fittings are inserted in position and screwed or riveted in place. Aluminum spars are easily cut with a hacksaw if oversize, and rough edges filed clean. When aluminum is used for the boom, it is a simple matter to have roller reefing, as the roller reefing gooseneck can be incorporated in the hollow extrusion. When using aluminum castings for aluminum spars, it is often necessary to file off rough edges. This is normal, and because of the relative softness of the metal, takes little effort. Also, a little oil or wax will make the fittings slip into the extrusion more easily. Fittings on wood spars are fastened with wood screws or through bolted. Goosenecks for wood booms usually have tang or strap-like members into which the boom fits. These tangs can usually be spread apart somewhat to suit the thickness of the boom. The gooseneck is bolted through the boom as are boom bails where required.

Masthead fittings should be detailed by the designer of boats with wood masts, and the larger the boat, the more elaborate the fitting. On simple mastheads which have only one halyard, all that is required is a sheave installed in a groove at the top of the mast. A similar sheave may be used at the clew outhaul on the boom. These sheaves use a pin axle driven through a hole, and the ends are peened (flattened) over to keep it in position. Sheaves are usually synthetic plastic material or metal where wire rope is used.

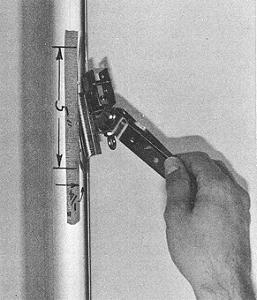

BOLT ROPE GROOVES

On spars which use a groove for the bolt rope of the sail, there must be a means by which the bolt rope can enter the groove. On wood spars, an area must be relieved using the method described later, or by the directions in the plans provided with the boat, if you are building your own boat. On aluminum spars which use a groove, a portion of the mast must be filed away with a coarse file (see Figs. 8-6 and 8-7). Do not cut away the groove excessively, and make sure all rough edges are smooth to prevent wear on the sail. A small fine file or rotary grinder plus emery cloth will do the job. Look at the end of the mast to determine the amount to remove. The length and position of the cutaway areas should be provided by the designer of the boat, or by the spar supplier. If the position or length required is not given, it can be determined by using the sail as a guide. Hold the sail so the top or head is 6" to 8" below the top of the mast, and stretch the bolt rope tightly along the mast. Mark the position where the tack of the sail falls along the mast, and relieve an area 5" to 12" above the tack, both for entry of the bolt rope and the gooseneck slide fitting. Remember that the relieved portion must be above the gooseneck when the gooseneck is positioned when pulled down by the downhaul (see Fig. 3-15).

8-6 |

8-7 |

|

FIG. 8-6 & 8-7 - Goosenecks used with grooved aluminum spars must be relieved in order to fit the gooseneck into the groove. Although a wood boom is shown, it could be of aluminum also. The relieved portion is also required for the bolt rope of the sail so the relieved area must be carefully determined. When the boom is pulled down by the downhaul, it cannot be in the relieved area; it must be below it as shown by Fig. 3-15. |

|