On the Mark: Epoxy, fillers and color matching

Continued...

Application examples:

Filleting

After planking the hull, clean up on the inside is required to get rid of the drips, runs and squeeze out. At the same time, the excess material can be formed into very nice fillets. Beware that staple legs may be hidden in the epoxy (not all my shots were 100% accurate). Therefore go slowly to avoid ripping your finger tip open on the staples. Glue in the cut takes a long time to work its way out and itches like mad.

Battens to frame and hull planking. This was shot after the boat was flipped and prior to clean-up sanding and re-coating. Note the perfect color match of the ash pieces, and good match from battens to hull to the left of the frame. The right side had sunlight reflections.

When I put the deck on, I did not add wood flour to the mix. This, coupled with the difficulty in reaching over the engine to smooth the fillets, made this a hard area to get nice thin fillets. Here you can see what happens when the epoxy is not color matched. This is the color of the colloidal silica and micro-fiber mix.

|

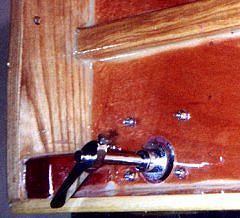

Mahogany hole and planking filler. Here are a couple of shots with of the mahogany final planking. Note the color match of the seams and lack of visibility of the staple holes. The "bad" seam plank had slipped during planking and was not visible under the stapling strips. Note the #6 screw head for a size reference. Also note that the staple holes are nearly invisible. The epoxy mix was a far superior filler for this purpose than conventional fillers. The epoxy mix blended in and stayed that way, the conventional fillers always show up - too hard to get a good match. The only downside to the epoxy filler is that it is MUCH harder to sand off than the conventional materials. |

Here is a shot of the other side near the transom during glue up. Note the extreme color difference of the epoxy squeeze out (and finger prints) compared to the raw mahogany.

White deck seamsThe white deck seams were done in epoxy to contrast with the mahogany and walnut. This gives the look of a caulked seam without the maintenance. For more photos of this see my web site: http://www.bronkalla.com/decking_fiberglass.htm

One final word. Test your mixtures on scrap material before you experiment with your boat. While the additives are generally interchangeable, test to be sure.

I will be presenting "Modern Boatbuilding Techniques", primarily covering the cold mold construction as used in the Riviera at the Wed Feb. 7th meeting of the Wisconsin Woodworker's Guild. For further information: http://www.wiscwoodworkersguild.org/ Visitors and guests are welcome.

Next month: stringers and frame mounting

We are very pleased to have Mark sharing his expertise with his fellow boat builders. If you would like to comment on this article to Mark, he can be reached at "builders at bronkalla.com". Replace the at with @. (Just trying to dodge a few spammers). See Mark's great web site for information on his Riviera project.