Inboard Hardware: Making the Shaft Hole

Page 4...

In use, the strut is located first and bolted in

position. The boring bar, which is the same diameter as the shaft to be used,

is inserted in the strut bearing to serve as a guide in drilling the hole.

Usually, in starting the hole in the bottom of the boat, the hole saw will tend

to creep forward. Holding a block with downward pressure on the hole saw will

tend to cut a cleft similar to that shown in Fig. 12-1 in order to give the

drill a chance to start to bite. The boring bar is powered by an electric drill

and will do a quick job (see Figs. 12-6 thru 12-9).

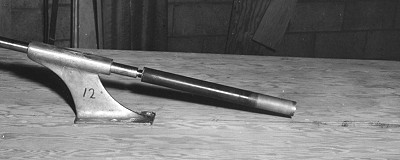

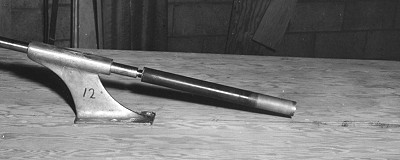

FIG. 12-6: The strut is bolted into position in the

manner described in Chapter 8. The shaft of the boring tool is then slipped

through the strut.

FIG. 12-7: The boring bit is threaded to the shaft. Note

that this shaft is the same size as the propeller shaft in order to fit firmly

into the strut.

FIG. 12-8: An electric drill is used to drive the boring

tool. When starting to drill, a helper should apply downward pressure with a

block of wood to prevent the drill from creeping out of position. Alternately,

a block of wood, pre-drilled at the required angle, as shown in PLATE 39, could

be used.

FIG. 12-9: The shaft hole can be drilled in a matter of

minutes using this tool.

Return

|