Stiletto

Construction Pictorial

Construction photos of the Stiletto; built by Don Ruffa and photographed by Glen Witt.

Prior to the photos in this pictorial, the frames were made using the full-size patterns or the Frame Kit purchased. The building form has been built per the plans and anchored to the floor.

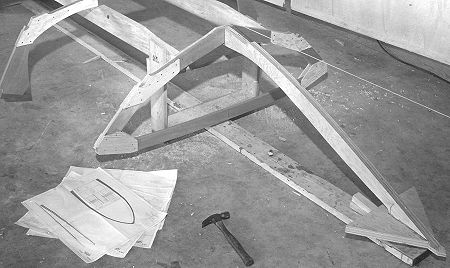

Fig 1: The stem-breasthook assembly butts to the floor timber of the #5 Frame and is blocked to the base member of the building form per the following procedure.

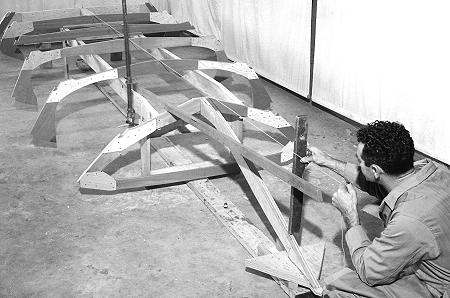

Fig 2: A chalk line or string is used to center each of the frames, transom and stem. The builder is using a level from the string to the centerline of the stem to accurately align the structure.

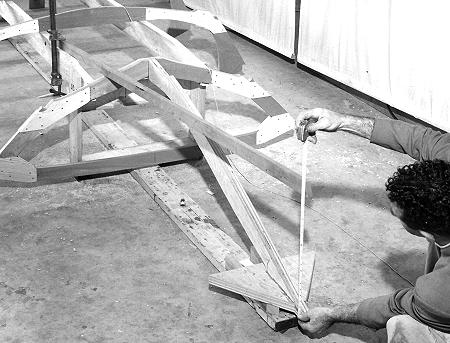

Fig 3: The setup level (top of the setup members) is extended by a straight-edge to the stem area. The tip of the stem-breasthook is carefully measured to the distance below the setup level noted in the plans. The stem-breasthook assembly is blocked and made rigid to the base member of the building form. Note: In this pictorial we will refer to "lines being fair". The chines, sheers and battens must be fair, with no bumps or dips. If in doubt about alignment at any point of construction, a long spline can be bent into the notches. If the line formed by the spline is unfair, something is wrong.

Terms: chine and chine log and sheer and sheer clamp are interchangeable terms.