Building the Squirt with jet power

by Paul Day

Continued

Nov 2003:

Fairing completed using #5 plane and 80 grit paper

glued to a 3x21" piece of 1/4" plywood. Final cuts made on what

remained on jet ski hull and began fit up.

Dec 2003:

Eight hull panels of 1/4" thick Marine Grade

Plywood applied to boat using 1" silicon bronze annular ring shank nails.

Joints between panels made using a 5 1/2" wide lap joint with plenty of

Gorilla glue. Next time I would go through the effort of scarfing the panels to

avoid the additional fairing and the inevitable bulge that appears when faired

and painted. Also need to be careful when nailing w/o pilot holes as mahogany

longitudinals were split in many locations. Initial fairing completed using

3x21" sanding board with 80 grit and entire bottom is epoxy encapsulated.

Transition pieces for jet ski-to-Squirt hull required as Squirt is quite a bit

flatter; the transitions were fashioned from laminations of 3/4" thick

plywood and epoxied. Jet ski hull attached with 14 countersunk machine screws

thru hull on bottom, 12 Silicon-bronze wood screws to transom. The boat now

weighs in at 140 lbs.

Jan 2004:

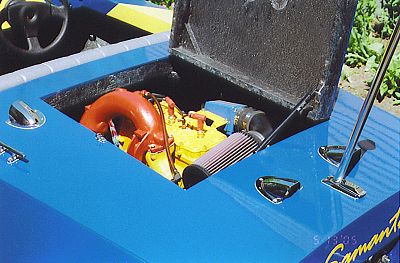

Boat flipped and deck beams cut from Douglas-fir and

secured. The jet ski hull is the gray part in the back, and the engine can be

seen hanging just above. Battens under engine mounts reinforced by adding an

additional 1x2" mahogany length between transom and frame #1. Engine

dropped in and it appears the spark plugs and the exhaust manifold are well

above deck level . . . will have to think about how to raise the deck in those

regions. All of the internal joints filleted with epoxy and #2 silica

powder.

July 2004:

Glad to be boat building again after a long kitchen

remodel project. Deck battens and hatch structure are now fitted and faired.

This boat will have a 24x20" hatch that will open to starboard. Internals

are epoxied, but my wood working skills are not so great, so I decide to go

with black Herculiner on all internal surfaces below the deck. This will also

aid in waterproofing and should deaden some of the noise. The 1/4" thick

plywood deck panels go in well, but still had problems splitting and hitting

the centers of the deck battens with the 1" annular ring shank nails. The

boat now weighs 171 lbs.

August/Sept 2004:

A garage roof project slows things down, but I get the

gas tank cradle, throttle bracket and seat frame made from 3/4" plywood

and epoxy encapsulated. Fiberglass applied to deck and first application of

microballons is done. The gas tank cradle (the 8 gallon jet ski tank will go in

front and is mounted crossways to keep it low), seat frame and throttle bracket

painted and installed.

A hatch bulge for the exhaust manifold made by making a Styrofoam master and then laminating 1x5" strips of fiberglass that have been soaked in epoxy with #2 silica powder. Overall the bulge is 5x12" and is about 3" high. The hull is now glassed and the first application of silica/microballons is complete. I'm using the Teleflex NFB steering selected for project as it appeared relatively compact in the photos. The rear portion of the cable had to be modified extensively to mate with the jet pump, but it looks as though it will do the job. Note that this system has a very high activation torque, and I may change it out in the future. Designed wiring harness to utilize all old parts in their new positions, but added wiring for bilge pump and lights.

December 2004:

Wiring harness is complete from 14-gauge multi strand

wire and is a dozen wires thick at some points. Installation of the harness is

complete but is difficult with the deck panels in place. I would definitely

install the harness and the steering before doing the deck panels. After making

a few careful measurements I took a deep breath and applied a small handsaw to

the deck to free the hatch lid. With the exception of a slight misorientation

on one side, the operation went well. The handsaw was easily controlled and

left a very thin kerf. The fuel pump, fuel filter, fuel selector switch, and

all electrical components mounted under deck on custom hangers bent from SS

sheet stock.

January 2005:

Holes cut for gas tank fill and exhaust port. A custom

exhaust tube needs to be made to fit between muffler outlet and exhaust port.

I'd like to have it in stainless but can't imagine what it would cost.

Instead, a master is made from Styrofoam disks that are glued together and

filed to shape. The master is then built up using fiberglass strips that have

been soaked in epoxy/#2 silica powder. After doing 3 or 4 laminations the

Styrofoam is dissolved by pouring acetone into the tube. A similar tube is made

to connect flame arrestor and air cleaner.

February/March/April 2005:

Applied paint to hull and deck. Used three coats of

sapphire blue Polyurethane from Interlux with wet sanding between coats; top

and bottom got a yellow stripe for accent. I'm happy with the finish, but

it takes some skill to apply: too wet and the paint forms bubbles on the

roller, too dry and poor coverage results. Best to apply wet with very

short-napped roller and to spread a lot. Final rolling should be with no

pressure other than that due to weight of roller itself. Also, installed

cooling air scoops, vinyl seat, lights, cleats, transom tie downs and hatch

hardware. Dropped engine and made final gas, cooling water, oil, and electrical

connects. Engine started and running in driveway on garden hose cooling.

May 2005:

Dropped the back end in the Mohawk River just enough

to lift off the bunks of the trailer…lots of water inside,

unfortunately. Perhaps I positioned the bilge outlet too low and will have to

launch with the bilge on. It appears as though most of the annular ring shank

nails on the deck have managed to back out just the slightest amount so that

the deck now has a riveted appearance. On the 20th, Samantha is underway for

the first time on the Mohawk River. No leaks and runs well at idle, albeit with

some vibration. Upon opening the throttle the stern squats down

considerably…don't see how she'll come up on plane like this.

Unfortunately about five minutes out we run into a boulder sitting a few inches

below the surface. Luckily the hull was not breached, but later inspection will

reveal a large chuck taken out of one of the aluminum skegs. Tough boat.

We're off that rock now and feeling good to have that behind us and giving

her some more throttle. At about one-third to half throttle there's a

remarkable transition and the boat climbs up on top of the water and stays put.

It's a very dry and stable ride and with little or no porposing; it felt

like over 40 at a touch under full throttle. Didn't make too many turns

other than a few broad, sweeping ones at mid-throttle that she took very well.

Overall very impressed with the performance and design of this boat and would

recommend it to anyone interested in building a small powerboat. Thanks for

your support.