Fife built by L. Banerd

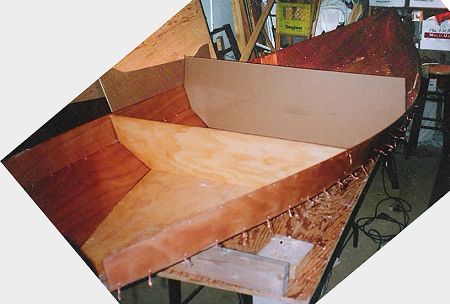

Here, the first strake stitched on. I live in British Columbia, Canada, where we have access to a lot of good wood, especially Douglas-fir. The bottom is Douglas-fir marine plywood, the strakes are Okoume marine plywood, and the solid wood is Douglas-fir.

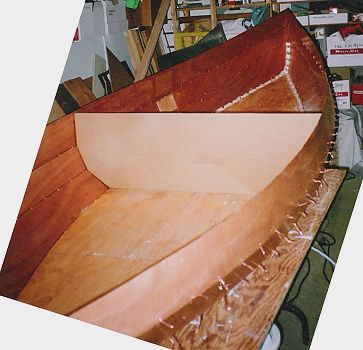

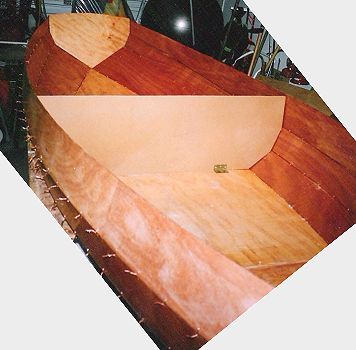

At this stage, all the strakes stitched on. The strength of the shell at this stage, with no epoxy fillets, was impressive.

A view aft of all the strakes are stitched on. The flat transom made it easier to achieve the designed hull shape.

Bulkheads and seat are in place. Also, the spacers for the solid fir gunwales are screwed in place while the epoxy glue dries.

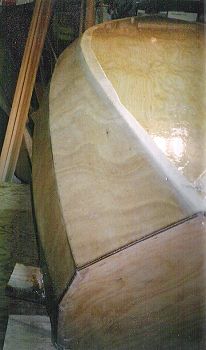

A view aft of the fillets, seam taping, and bulkhead. Building took place in an ordinary one-car garage. This took some careful maneuvering, but it worked out.

The first layer of fiberglass cloth covers the side. At the next stage, a layer of cloth went over the bottom and overlapped at the seam.

All the fiberglass cloth is on and sanded smooth. The ragged edges at the gunwale need to be cut off.

The hull finished and painted, the boat is upright again. The gunwales are on, but not the aft seat.

The completed boat ready to roll off to its first launch. The large hatch makes an excellent seat and gives access to a huge storage area underneath. The finished boat weighs just over 100 pounds. This being my first project, I overbuilt the epoxy fillets and used more coats of epoxy than was probably necessary.

On the way to Lake Okanagan. The trailer is a very light (95 pounds) aluminum model designed for light boats, canoes, and kayaks.

At a Lake Okanagan beach, ready to launch. The trailer is light enough to use as a dolly.

Rowing for the first time, Lake Okanagan in March 2007. The boat was a delight: it floated on its lines, tracked perfectly, and was easy to get up to speed. Also, it carried two adult men totalling 400 pounds with ease. The forward rowing position and movable oar locks are great design features.

The project took 2 years of casual evening work. I worked only in the winter months (October to April) and on evenings when I felt like it. Where epoxy is concerned, I found it best to take my time, get it right, and make sure it is cured before the next step.

December 29, 2008

Close-up of the boat underway in the harbour at Gibsons, B.C.; it shows the lines and size well.