Bullet by Mark & Luke Finnila

April 17, 2008

Our chine log landed nearly vertical at the stem. Achieving

a better angle was possible, but at the expense of landing

even closer to the sheer. I have a complete steamer for my

woodworking, but it was broken in two during our last move.

(I should have fixed it!)

Wood is very accomodating. I laminated a half inch of

Douglas fir to the front portion of the chine. This allowed

me to correct the angle of the chine (using a Bosch power

planer for the rough work) so that the side panel could lay

flat between the chine and the sheer.

The chine is fixed and fairing is complete. Notice that the

sheer has a flat spot in it near the floor side. I should

have faired it farther as this created a gap between the side

panel and the deck that had to be filled with thickened

epoxy.

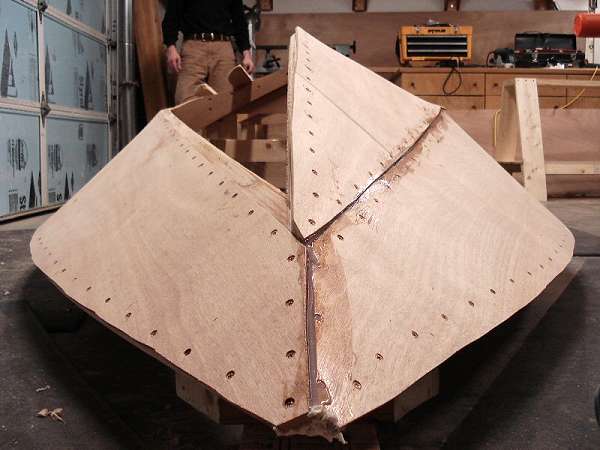

Both side panels and one bottom panel installed. I used a

black crayon on the edge of the installed side panel near the

bow to mark the underside of the bottom panel during fitting.

I cut too much off the very tip of the bottom panel during

rough fitting, but filled the small gap with epoxy.

Wise folding seats at a 10 degree recline. I installed the

first rear deck beam at a matching 10 degrees so the seat

backs rest solidly against it. That will relieve stress from

the seat hinges. We filleted the battens and chines.

Simple fuel tank and battery tray. This is a 13-pound PWC

battery that meets the manufacturer’s requirements for

our engine.

Three coats of System Three Silvertip resin provided a good

build up. We plan to paint the whole boat leaving no wood

exposed.

This is as far as we got prior to dropping the boat off for

motor installation on 8 Apr 08. We bought a 2007 Yamaha 25

hp, two-stroke, long-shaft, with electric start and remote

motor. Motor installation should be finished by early May. We

are hoping for an early June launch.

19 January 2009 Update

Cockpit: PWC mirrors greatly improved view for monitoring

skier. Switch box on port side controls bilge pump,

navigation/anchor lights, and bilge blower. Dash includes an

inexpensive stereo system, tachometer, depth finder, and

horn. Horizontally mounted horn on starboard bow collected

water, but I drilled a small hole that allowed it to drain

without sacrificing too much sound! Notice the ski buoys

stored under the deck.

Stern: The Wise seats are very comfortable and their folding

feature allows us to store items under the stern deck. The

bilge blower vent is located on the port deck. The bilge pump

drains to the motor well.

Transom: The standard transom height is about 1

½” too low for a Yamaha long-shaft motor. We

could raise it, but the current height probably allows

sharper turns before prop cavitation. (I’ll take the

sharper turn over the increased speed!) Interlux Micron Extra

bottom paint did a great job of eliminating slime as we kept

the boat moored most of the summer at a warm lake in North

Carolina. Smart tabs were an easy install and greatly

improved planing, cornering, tracking, and eliminated a

porposing/chine walk issue. The 11” pitch, stainless

steel, Turbo Hot Shot prop is a good for all-around use. A

13” pitch prop would increase speed, but sacrifice

towing ability.

Father and Son Build Complete: The American flag graphic is

a vinyl decal from Raceline Digital graphics in Canada. It

was pricey, but definitely completed the look. This is a

photo of two very satisfied customers/builders!

On the Water: This is what it’s all about…a

boat on the water.

NOTE: See Mark's story in WebLetter 126