8-27-03

Please find attached photos of the Bo-Jest progressing.

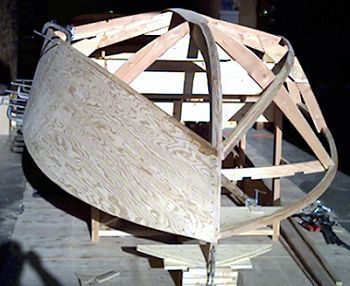

As can be seen the port side planking is going on, although the forward section was quite difficult to bend, even with several hours of treatment with wet towels. The butt joints have been installed onto each panel in sequence so that one half of the block is waiting for the next plank section. Trying to purchase plywood in lengths over 8' was both costly and time consuming, hence this sort of joint.

I don't know if it is common practice, but the 3/8 marine AB panels I purchased ended up being 1/32" oversize and five plies thick. This has proven to be a very stiff plywood and to get to the point, I'm behind schedule because of wetting and "encouraging" the wood into compliance. No matter, the job is getting done.

Finally, pictures of the powerplant are included, a 60's IHC C-135 engine which is a wet-sleeved industrial engine governed at 2200 rpm maximum. Although it's 135 cubic inches, it yields only 36 HP, but it will provide that without a whimper in continuous duty. Coupled to the engine is a Hurth ZF-25 hydraulic transmission which features an 8 degree output down angle coupling to reduce engine fore/aft angle. This engine is a bit large for the application, so engine beds will be heavy, skeg increased to 3" and 1-1/4" drive shaft used.