Key Largo by Dave Vangsness, Riverside, California

4 April 2011 (Cont'd)

Each layer was applied with epoxy rolled on with a paint

roller and held in place with staples. I shot the

staples through cardboard "washers" and every one

was removed after the epoxy dried. I lost count of the

thousands of staples. I paid the kids 5 cents per

staple for removal services. After all layers were

complete, bronze screws and mahogany plugs went around the

hull at the chines, sheer and double along the keel.

The hull nearing rough completion before stain and

fiberglass. The mahagony sides have been applied and

the bottom fairing is nearly complete.

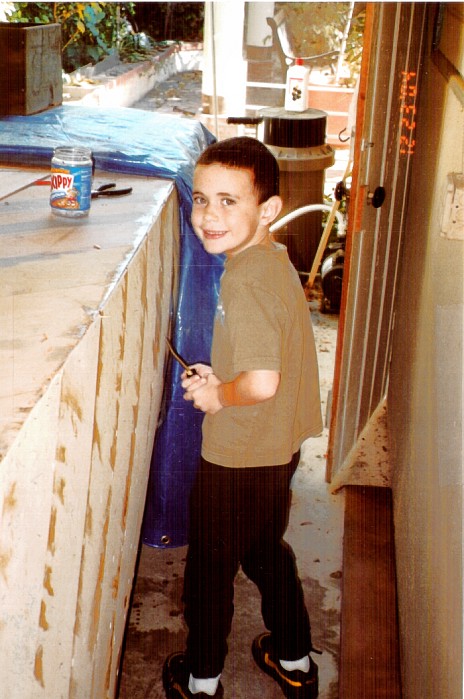

My youngest boy helping out. He will be 13 by the time

we have the 'sea trials' in 2011!

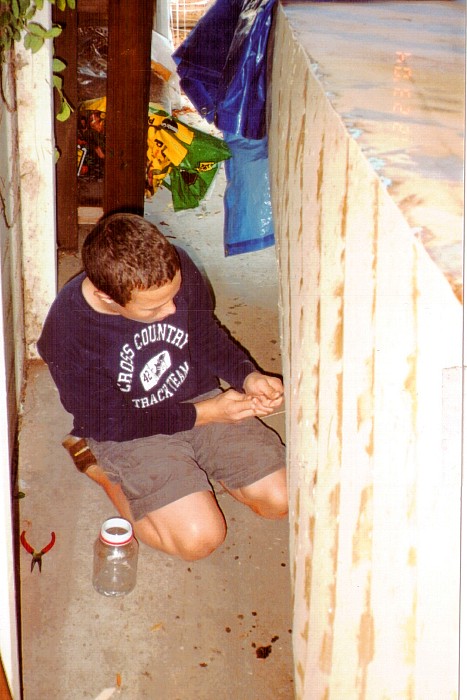

My oldest boy who will be 19 and home from college for Spring

Break on 'sea trials' day!

The hull receiving the single layer of fiberglass cloth used

on the entire hull. It is draped and ready for epoxy

'wetting out.'

The hull after fiberglass cloth and receiving multiple

additional coats of epoxy resin. The shaft hole is

visible, but was actually drilled before the fiberglass was

applied.