A place to share YOUR boat building story

Glen-L Marine Designs - 9152 Rosecrans Ave. - Bellflower, CA 90706

In this issue

In this issue

-

2008's Top Boat Names

-

Glen-L Boatbuilder of the

Month

-

Featured Design:

Bandido

-

Designer's Notebook: Make Your

Own Hardware

-

Anchors by ArtDeco

-

Photos sent in since the last

WebLetter...

-

Shop Talk: Clever

Tips

-

Recent email

-

eMail of the Month

GLEN-L Update

- All of us here at Glen-L really appreciate every photo you send us of your boats, whether it be in the construction phase, the finishing phase, or that wonderful time when you finally get to put her in the water. We especially look forward to the photos you take that show the result of all of your efforts as you are out on the water with your family and friends. Those of you who have completed your crafts know the special feelings of pride and accomplishment you get from the looks of admiration when you tell people "I built her myself."

- To that end I want you to know that I am working every day to get all of your photos up on the website. If you've submitted photos and haven't yet seen them posted it's only because there's a bit of a backlog that's taken me longer than expected to clear, not because we don't value every photo you've sent to us.

- I sincerely hope each of you who are building one of our boats, or have completed one (or more) will take a couple of minutes to write and tell us a little about your feelings and experiences, dreaming about, building, and/or enjoying your boat. THESE are the stories that really make these WebLetters fun and interesting - "inquiring minds want to know", you know.

-

I don't know the origin of the quote, but I've

seen it ring true over and over again:

"A sorrow shared is a sorrow halved, but a pleasure shared is a pleasure doubled."

Won't you double your pleasure by sharing your stories with us?

Until next month . . .

Editor

2008's Top Boat Names

FirstBoat.com has announced its

list of the most popular boat names of the past year. The

list includes nautical puns, tributes to recent movies and TV

shows, and an overall celebration of the boating

lifestyle.

Here are the top ten most popular boat names for 2008:

- Happy Ours

- Carpe Diem

- Aqua-Holic

- State of Mind

- Anchor Management

- The Office

- Feelin' Nauti

- Yes Dear

- Sundance

- Serenity Now

In general, most of the names on this year's list of top boat names illustrate that boaters are imaginative and passionate individuals who like to have fun.

Glen-L Boatbuilder of the Month

George Redden - Malahini

George finished his Malahini in August 2007 and launched late that month and tells us "she runs very well. The 60-HP, 4-stroke Mercury outboard is exceptional; instant start, smooth, quiet, nice idle operation and pushes the boat to 40 mph at max revs of 6600 rpm (fast enough for me!)."

"The most common onlooker questions are 'What year is it?' and 'Is that an old Chris Craft?' I stopped varnishing at seven coats so that the Honduras mahogany looks like real wood and not something buried under fifteen coats of plastic."

George says "The cockpit layout has proven to be very good, except I should have made the walk-through four-inches wider. It is difficult for me to kneel down when accessing the bow storage compartment, which holds the homemade cockpit cover and auxiliary gas can. The mid hatches are fitted out to hold fenders, docking lines, cooler, waste container, fire extinguisher, etc. The aft hatches give access to the fuel tank, battery, bilge pumps, general storage and the auxiliary electrical panel with battery manual switch, pump fuses and hour-meter. The bottom of the back seat is hinged for storage under it with racks for the boat hook, boarding pole, and cockpit cover support."

"Betty and I will be entering a few ACBS shows this summer and we'll let you know if anything eventful happens."

"Happy boating!"

-- George & Betty Redden,

Staunton, Virginia

Editor's Note: See more about George & Betty's Malahini

in the Project Registry and in Customer Photos.

Featured Design: Bandido

The BANDIDO is a 30' luxury offshore

performance boat offering high-tech performance and

construction methods to match the exotic production boats, at

a fraction of the cost. You can build yours in Wood or

Fiberglass with a wide array of powering options. The

trailerable hull, capable of 50+ knot speeds in offshore

conditions, features a 22º minimum deep vee with

radiused keel section and lift strakes.

Your BANDIDO can be set up with single or

twin inboards (either diesel or gasoline), driving through

I/O units, vee-drives, surface propeller drives, or with jets

(with minor modifications). Or use twin outboards if you like

(a single outboard engine is also possible). The choice is

yours, and a large fuel capacity means long range even with

larger motors.

Your BANDIDO can be set up with single or

twin inboards (either diesel or gasoline), driving through

I/O units, vee-drives, surface propeller drives, or with jets

(with minor modifications). Or use twin outboards if you like

(a single outboard engine is also possible). The choice is

yours, and a large fuel capacity means long range even with

larger motors.

Because of the high performance potential of the BANDIDO,

construction is aimed at the conscientious builder willing to

follow instructions and use the best materials. With the Wood

Version, we specify cold-molded wood veneers or plywood

strips laid up in multiple layers diagonally applied, all

bonded together preferably with an epoxy bonding and

encapsulating system. A layer of fiberglass on the exterior

is used for abrasion resistance and added durability. A

carefully designed structural "grid" framing system

emphasizing longitudinal stringer webs makes a strong, yet

lightweight hull.

With the Fiberglass Version, several materials and

"one-off" methods are detailed, depending on the

builder's budget, abilities, and desires. The fiberglass

planking option is probably easiest and cheapest of the

fiberglass methods for the novice, but not the lightest in

weight. The sandwich core option, using a core material of

PVC foam or end-grain balsa, is perhaps a bit more costly,

but somewhat lighter in weight. Both systems result in strong

boats well within the average amateur's abilities.

The High-Tech version is for the builder who wants the

ultimate in light weight and performance potential. The

fiberglass hull consists of a sandwich core using rigid PVC

foam or end-grain balsa. The super-thin high strength skins

are made from aerospace-type S-Glass uni-directional and

triaxial fiberglass reinforcements. The high-tech version can

be built using conventional "one-off" methods, or

for the more adventurous type, vacuum bag methods suitable

for many amateurs more fully explained in our text, FIBERGLASS BOATBUILDING FOR AMATEURS.

This system can result in a structure that weighs less than

2000 lbs! Procedures used to build the high-tech version are

not any more difficult than the other methods; they do,

however, require care and attention to detail.

Regardless of the construction method, all BANDIDOs feature

a plush cabin with galley provisions and a head, a spacious

and safe cockpit, and a roomy sun deck lounge. All plans

include Full Size Patterns and comprehensive instructions to

simplify construction.

So why wait? Fulfill your dream now and save thousands.

AnchorsA nchors are as old as boatsAccording to ancient lore They hold on to the seabed And keep you off the shore Some have flukes to dig in Others work by mass alone Some are permanent moorings For anchoring at your home For temporary holding work There are anchors of many types Danforth, Northill or Claw Will all fit in your hawse-pipe Some say for better holding Go with a mushroom or a plough Though breakout can be difficult You’ll need strong cleats on the bow Some older types I’ll mention The stockless, fisherman or screw Not often seen much anymore But in a pinch, they’ll do The simplest kind of anchor For use on a small boat A paint can full of concrete Or just a rock and a rope Whatever type you choose To hold you in wind and sea Be sure to tie the bitter end If you lose it, don’t blame me -ArtDeco |

Photos sent in since the last WebLetter... |

--- Benjamin Franklin, 1746 (rumored to have been said whilst building his first Glen-L designed boat) |

Shop Talk: Clever Tips

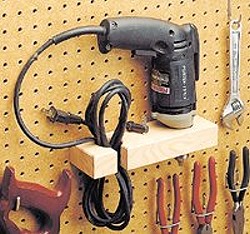

Drill

Holster

Here's a handy way to store your electric drill, sent in

by Dick Grote of Palo Alto, California — a

"holster" that hangs on a pegboard rack.

The holster is a scrap of "two-by" material with

two openings cut in it. The drill chuck fits in a large hole.

And the power cord slips into a keyhole-shaped notch.

By installing two L-hooks in the back edge, you can hang the

holster securely on the pegboard.

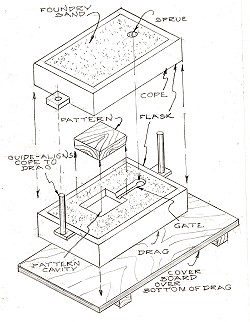

Assembly

Blocks

Sometimes you almost need a third

hand to assemble a project, especially working with large

pieces of plywood. To help keep the pieces aligned, use

assembly blocks made from scrap.

Sometimes you almost need a third

hand to assemble a project, especially working with large

pieces of plywood. To help keep the pieces aligned, use

assembly blocks made from scrap.

Make these blocks from medium density fiberboard (MDF) with

intersecting dadoes cut in the middle (pieces of plywood or

solid wood would work as well). Just set the workpieces in

the assembly blocks or place the blocks on top to hold the

pieces in place until the clamps are installed.

Recent email:

Subject: Boatbuilder Forum

Date: 12 January 2009

I just discovered the forum!

Nice job on the WebLetter (love the Jimmy Buffet

song, too)!

-- Ray Boller

Subject: Outrage

Date: 14 January 2009

I sent you a Power Point presentation of my building the Outrage.

I've built 4 Glen-L boats - one sailboat and two copies

of TNT and now the "Outrage." This

one was the most fun. I am an architect, but my hobby is

cabinet making.

Your plans are very accurate and easy to work with. I would

recommend them to anyone that is ready for a boatbuilding

project.

-- John Wilmot

Edgewater, Maryland

Subject: Great Information

Date: 22 January 2009

-- Brad Lynskey

Arkadelphia, Arkansas

Subject: Glen-L Website

Date: 27 January 2009

I have great childhood memories of helping my grandpa wax and polish his 1950s Chris-Craft speed boat. Maybe that's why I hang a new Wooden Boat Calendar up in my office every year...

-- Andy

EZ Woodshop.com

Editor's Note: You'll find Andy's excellent website

Andy's EZ Woodshop quite interesting.

Subject: Acapulco Camper

Date: 27 January 2009

Thanks for the great plans.

-- Steven Gourley

Trenton, Ontario, Canada

Subject: "Build Your Dream Boat" Newsletter

Date: 25 January 2009

You deserve a marketing award of some type. I smile when I see Glen-L eMail in my inbox - your messages usually arrive just when I have talked myself out of a boatbuilding adventure.

And through some psychic ability you always seem to hit the points I've used to talk myself out of it.

-- John Haley

Henrietta, New York

Subject: "Ribs Up" Party

Date: 1 February 2009

-- Jack Waggoner

Sacramento, California

eMail of the Month

Subject: Thank You

Dear all at Glen-L, thanks for all the information

that you sent. My project is going slow, but it is

going. Stem is connected to the breasthook, side

braces are done, transom is half way and hopefully

will be ready for mid-February when I plan to build

the platform. London, England |

GLEN-L boats, of course