A place to share YOUR boat building story

Glen-L Marine Designs - 9152 Rosecrans Ave. - Bellflower, CA 90706

In this issue

In this issue

-

In Memory of My Mother…Vera

Irene Witt

by Gayle Brantuk

-

Mr. Schott's Superb Sea Trip

by Ken Schott

-

Glen-L Boatbuilder of the

Month

-

Response to the "Tool

Junkie" by John Downing

-

Designer's Notebook: Does Your

Transom Droop?

-

The Haulout by ArtDeco

-

Photos sent in since the last

WebLetter...

-

Glen-L Walk-in Customer of the

Month

-

Shop Talk: Impact Drivers vs.

Driver Drills

-

Recent email

-

What Kind of Bait?

GLEN-L Update

My how the months fly by! It's almost Spring and I'm

sure many thoughts are turning to just how soon we can get

our boats out on the water. At Glen-L we are eager to hear

about all of your adventures, both in constructing and in

enjoying your boats out on the water.

This month's WebLetter holds a lot of interesting

content, because several of you have sent in articles for

everyone to enjoy...

- Gayle has written a tribute to her wonderful mother

- Ken Schott sent in a great story involving his Double Eagle

- Greg Kelso and the Land of Lincoln Power Squadron's experiences with their Tubby Tug

- John Downing's confession about... well, you should read it for yourself...

Until next month . . .

Editor

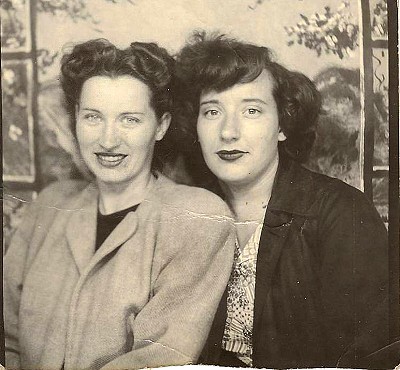

In Memory of My Mother…

Vera Irene Witt

by Gayle Brantuk

"MRS. MARINE" HAS PASSED AWAY

yes, "Mrs. Marine", as she was

called at times throughout the years, has passed away. Since

the family business name is Glen-L Marine after Dad's

name, many assumed mom's last name to be

"Marine"…

yes, "Mrs. Marine", as she was

called at times throughout the years, has passed away. Since

the family business name is Glen-L Marine after Dad's

name, many assumed mom's last name to be

"Marine"…

My mom was the best mom in the world, as I must have told

her a hundred times. She came from a large family of eight

children of which there were two sets of twins and mom was

one of them. She and her sister Vena were fraternal twins

which means they didn't really look anything like each

other but they were very close. The other set of twins was

Uncles Billy and Bobby and they are identical mirror twins.

Mom would say it was like looking into a mirror-one was

right-handed, one was left-handed.

Mom grew up in the

small rural town of Pawnee Rock, Kansas where she went

through school, finishing up High School in Bremerton,

Washington. Mom and Vena moved to Oceanside, California after

high school and got jobs as operators for the phone

company.

Mom grew up in the

small rural town of Pawnee Rock, Kansas where she went

through school, finishing up High School in Bremerton,

Washington. Mom and Vena moved to Oceanside, California after

high school and got jobs as operators for the phone

company.

Years later, Mom was working at a drugstore when she finally

met my father. At that time, she was divorced with a young

6-year old daughter, Janet. Mom used to say that Dad seemed

to need an awful lot of toothpaste and kept coming into the

drug store to pick that up while she was working. Mom and Dad

were married in 1956.

Mr. Schott's Superb Sea Trip

by Ken Schott, Double Eagle Builder

BUILDING A DOUBLE EAGLE IS FUN EVEN BEFORE IT'S DONE

My work is secure for the moment,

too secure actually; working too much overtime to finish the

boat.

I took the Double Eagle out in some tough seas and

about that time I was thinking about the bilge pumps. With

this open cockpit boat in 5-7 foot seas, the whole idea of a

big one coming over the bow seemed a possibility. Bilge

pumps, or, ummm, "crash pumps" really came to

mind.

I took the Double Eagle out in some tough seas and

about that time I was thinking about the bilge pumps. With

this open cockpit boat in 5-7 foot seas, the whole idea of a

big one coming over the bow seemed a possibility. Bilge

pumps, or, ummm, "crash pumps" really came to

mind.

But, this hull took it all in stride. I did notice that if

the bow got plunged into a big wave, it would split the wave

right on up to the sheer, and as the wave parted, the

buoyancy lifted at the same time, so she never took on any

water.

This kind of weather is why I chose the Lobster boat running

hull. Thus far she has lived up very well to the 'sea

kindliness' description in the Glen-L catalog.

Without a doubt, your design can take more punishment than I

can. On the run out, I was running about 20 mph into a 25 kt

wind. So, the wind was making my eyes water at the same time

the wind/spray was covering my glasses. When I could not

indentify a buoy any longer, I turned back for home and the

downwind run. The seas seemed bigger on the downwind run

since the boat wanted to go surfing if I slowed down. Surfing

was fun, but I powered it up to get on home for dry clothes.

This is where it got interesting running with a lot of power

on in a following sea.

Some of the waves were big enough to look over amidships and

look down into the trough. After awhile this downwind running

was kinda fun and I began playing with the sea going running,

then across, the seaway.  About this time, the

evening sun had a row of channel markers lit up bright. What?

channel markers? Where was I? There ain't any markers on

the way back to the boat ramp (the ramp where my trailer was)

-

About this time, the

evening sun had a row of channel markers lit up bright. What?

channel markers? Where was I? There ain't any markers on

the way back to the boat ramp (the ramp where my trailer was)

-  Aw crap!!

Aw crap!!

So now I go to the nearest marker for a number and pull out

a paper chart to look at. Keep in mind that everything in the

boat is already wet; the wind already blew a plastic bailing

bucket out. This paper chart goes away with the wind and all

I got in my hand is some paper mush. I know I am not too far

from the mouth of St. Catherine Sound because I can see

the mouth, but how in hell did I get into the ICW

headed for Florida?

All that don't really matter 'cause I am now low on

gas, cell phone in the truck, it's getting late, and

there isn't anybody else out here on a day like this. I

went back out into the sound and started for home all

over.

So, ummmm, yeah, the boat can take a lot more punishment

than I can.........

and his Project Registry entries.

Glen-L Boatbuilder of the Month

Land of Lincoln Power Squadron - Tubby Tug

Illumination began as a

set of plans purchased from the Glen-L Marine Company in

Bellflower, California. Funding for its construction was due

to a generous grant from the Boat US Safety Foundation.

Land of Lincoln Power Squadron, a unit of the

United States Power Squadrons, based in Springfield,

Illinois, began construction of the plans called "Tubby

Tug" in February, 2007. Members of the Land of Lincoln

Power Squadron (LLPS) voted to begin this project as a means

to promote public awareness of USPS and its goal of

increasing boating safety through fellowship, education and

civic contribution. In addition, the vessel would be used as

a visual aid for boating safety training helping to

demonstrate proper boat handling, use of compass and GPS for

navigation and proper protocol for VHF marine radio

usage.

Land of Lincoln Power Squadron, a unit of the

United States Power Squadrons, based in Springfield,

Illinois, began construction of the plans called "Tubby

Tug" in February, 2007. Members of the Land of Lincoln

Power Squadron (LLPS) voted to begin this project as a means

to promote public awareness of USPS and its goal of

increasing boating safety through fellowship, education and

civic contribution. In addition, the vessel would be used as

a visual aid for boating safety training helping to

demonstrate proper boat handling, use of compass and GPS for

navigation and proper protocol for VHF marine radio

usage.

LLPS members collectively cut, sealed and

assembled 1/4" inch marine-grade

plywood for the sides and 3/8" marine-grade plywood for

the bottom. The cabin was built and installed. The entire

vessel was encapsulated with fiberglass and painted with

water-based epoxy paint. The vessel was completed in early

May, 2008 and was christened and launched on May 17, 2008 in

Springfield, Illinois to kick off 2008 National Boating

Safety Week. Since that time it has been seen in local

parades, the 2008 Illinois State Fair in Springfield and used

in various boating safety classes. Illumination is a

working boat and is equipped with all the necessary equipment

to meet or exceed U.S. Coast Guard standards. It has floated

on several bodies of water including the Mississippi

River.

LLPS members collectively cut, sealed and

assembled 1/4" inch marine-grade

plywood for the sides and 3/8" marine-grade plywood for

the bottom. The cabin was built and installed. The entire

vessel was encapsulated with fiberglass and painted with

water-based epoxy paint. The vessel was completed in early

May, 2008 and was christened and launched on May 17, 2008 in

Springfield, Illinois to kick off 2008 National Boating

Safety Week. Since that time it has been seen in local

parades, the 2008 Illinois State Fair in Springfield and used

in various boating safety classes. Illumination is a

working boat and is equipped with all the necessary equipment

to meet or exceed U.S. Coast Guard standards. It has floated

on several bodies of water including the Mississippi

River.

Illumination carries the required

navigation lights for night-time operation and is outfitted

with a lighted compass, a remote control searchlight and VHF

marine radio. Also onboard is a first aid kit and Coast Guard

approved fire extinguisher. A GPS unit can also be mounted on

the dash to assist in navigation. The center stern seat has a

bilge pump enclosed and there is a separate storage

compartment in the bow. For added safety, the bow

compartment, center seats and rear seats (port &

starboard) have been filled with flotation foam making the

boat virtually unsinkable.

Illumination carries the required

navigation lights for night-time operation and is outfitted

with a lighted compass, a remote control searchlight and VHF

marine radio. Also onboard is a first aid kit and Coast Guard

approved fire extinguisher. A GPS unit can also be mounted on

the dash to assist in navigation. The center stern seat has a

bilge pump enclosed and there is a separate storage

compartment in the bow. For added safety, the bow

compartment, center seats and rear seats (port &

starboard) have been filled with flotation foam making the

boat virtually unsinkable.

The Tubby Tug design is nine feet in length and has a beam

of 4½ feet. It is designed to carry 600 pounds which

equates to four adults and is rated for up to a 5 HP engine.

Currently, Illumination has no engine, however, once

funds become available the steering unit will be utilized

with the new engine to enable helm control of the vessel.

Greg also supplied us with more information as follows:

The article pretty much explains who we are and what we did.

We took over three hundred pictures during the build and

launch process.

The boat was inspected and licensed by the IL DNR and was on

display at the Illinois State Fair. We probably had at least

a thousand kids sit in it and play with all the bells and

whistles. Now it will be on display at the Chicago Boat &

RV show, the Chicago Strictly Sail show and the Schaumburg

Boat Show. Then, on to the Peoria Boat Show and back in

Springfield for our show. We plan to make the rounds of local

lake clubs and parades this year as well.

Like all the other people who post pictures and experiences, it's incredible the attention this boat draws both on the water and towing down the road!

and learn about the United States Power Squadrons.

Response to the "Tool Junkie"

by John Downing, Amherst, New Hampshire

D ear Glen,

Yes, I too am a "Tool Junkie," but I do love to

rehabilitate and use them. Power tools are so much more

convenient and fast, but sometimes, too fast and too

convenient, and actually, too darned messy!

For example, take the power sander. Yep, it sure works

great, but you know a properly sharpened cabinet scraper

works as well, if not better, and you are not fighting all of

that sawdust!

The power jointer is a real convenience, especially at

trimming your finger nails and those unsightly and obviously

unneeded finger tips. However, a well-tuned plane is a thing

of beauty and a joy forever!

Power saws can genuinely let you make small pieces of wood

out of big ones, really, really fast. But a well-sharpened

hand saw cannot be beat for trimming, particularly small

items and tough to get at places.

The point of this is that most hand tools are not used

because they come from the factory poorly tuned and/or

sharpened, and sharpening is something that must be

diligently practiced in order to gain the skill you need. I

used to teach a class in preparing a wood plane for use.

Except for Lee-Nielson, most new hand planes are at best,

kits. They must be taken apart, cleaned, the soles lapped and

flattened, the frog filed and cleaned up, the blade properly

sharpened and the chip-breaker/blade union cleaned up. Most

folks buy a new plane, adjust the blade, try it out and

realize it is a lot of work for little result and so the

plane goes on the shelf until the kids hold a garage sale

after dad has gone to that woodworking shop in the sky.

Don't even get me started on sharpening a hand saw!

Bottom line? For most folks, the tool is just that, a tool.

It is a means to an end. In this forum that means getting

afloat on a vessel of your own creation. For some of us,

tools are more than just a means to an end. For us, the

journey is just as important as the destination, and the feel

of a properly tuned and sharpened plane, cutting a

translucent shaving from a long, white oak board, can only be

described with one word...sensuous!

I am a Scouter in the Boy Scouts of America. I like to teach

woodworking and I focus as much as possible on hand tools.

They are safer, better controlled and teach the basics to

young apprentices. My goal for this coming summer is to build

a treadle lathe for the boys to use in learning to turn wood.

When they are older, they will most likely transition to

power tools, but the hours spent straddling a shaving horse,

shaping something with a drawknife and spokeshave, and then

chucking it into a treadle lathe to finish the product will

be remembered and cherished, and really, they will remember

the feel of the tools and the wood and the relative quiet

that is associated with the use of hand tools.

When I started this letter, I had a humorous intent, but I

find that the difference between hand tool and power tool

users is profound and almost religious. As a result, I guess

I got a little carried away with the seriousness of the

subject. The one power tool I will not give up is the

drill/screwdriver. I might be a romantic, but I am not a

masochist!

P.S. Glen, thanks for all of your great columns! The one

about casting was spot-on!

Designer's Notebook: Does Your Transom Droop?

|

The HauloutBoats that live in a slipMust have their bottoms cleaned They all make a yearly trip To a boatyard, that's where I mean When the time came for mine I called up Kettenburg Marine And made an appointment For my sailboat to be cleaned I would take the boat in by seven That's before my job you see They'd clean and paint the bottom To be done that afternoon by three As we approached the dock My wife was at the helm I was up on the bow Confident she knew that realm As I looked into the yard The sun was breaking light The marine railway cradle Was nowhere in my sight It must be under the water I realized all too late We were going way too fast For us to change our fate The keel then hit the cradle We came to an instant stop But I was not hanging on And into the bay I did flop Many of the boatyard workers Laughed because I was wet Seems when they saw us coming They had all placed a bet The boat had minor damage My dignity was shot to hell My wife was very embarrassed And repairs meant a day as well The moral of this story The truth can now be told When sailing into a boatyard It's better slow than bold -ArtDeco |

Photos sent in since the last WebLetter... |

Glen-L Walk-in Customer of the Month

Reed and Traci Daniels of Rigby,

Idaho suprised us here at Glen-L by driving all the way to

Bellflower in order to purchase a "boatload" of

Glen-L products (notice the Glen-L Hat Reed is sporting - don't

you want one too?!). Traci and Reed visited with us at

Glen-L's Intergalactic Center of Operations the morning

of March 19, and were kind enough to share with us pictures

of their Glen-L Crackerbox and Glen-L Monsoon, and regale us with stories of

their adult exploits and childhood memories.

Reed told us that his father was a "hardcore"

boater, and that once when asked if he ever though of using

cavitation plates on his Crackerbox his

dad firmly responded "Cavitation plates are for sissies

- just hold on!!"

Many thanks to Traci and Reed for their warmth and

friendship, and for entertaining Buckshot too!

the answer to "How do you eat an elephant?" "--- One bite at a time." |

Shop Talk: Impact Drivers

vs. Driver Drills

HOW DO IMPACT DRIVERS "MELT SCREWS IN"?

Until you try one, you simply

won't believe how effortlessly an Impact Driver drives

screws. Unlike driver/drills that simply rotate the drill or

driver bit, Impact Drivers apply a series of high-speed

rotary hammer blows to the driver bit, just like the impact

wrench the tire guy uses to install lug nuts. That rotary

force minimizes the axial force (pushing) required to keep

the driver bit in the recess, so screws seem to just

"melt" right in!

Cordless impact drivers have been gaining popularity for some

time now. Today, it would be hard to find a professional or

serious home shop that didn't have at least one. If

you've priced them, however, you may have noticed that

they fetch a different price than a typical cordless drill.

There's a reason for that: Despite the similarity in

appearance, they're completely different tools. An impact

driver, like the Makita BTD130FW 14.4-Volt Lithium-Ion

Cordless Impact Driver

,

may look like a sort of wimpy drill/driver, but in reality,

it's a much more sophisticated mechanism, and provides an

entirely different fastener driving experience.

How does an impact driver work? There are several variations

in mechanical design, but in essence all impact tools work

like this: A rotating mass in the tool called a

"hammer" is accelerated independently of the

"anvil" - the output shaft that engages with the

head of the fastener. When the hammer has built up a certain

amount of energy, it is brought into contact with the anvil,

creating an impact which instantaneously applies torque to

the fastener. The cycle repeats and repeats, on the order of

thousands of impacts per minute. The result is a high level

of torque delivered to the fastener with very little effort

on the part of the user.

There's really no comparison between an impact driver

and a conventional drill/driver when it comes to fastener

driving force. The Makita BTD130FW impact driver, for

example, delivers a maximum torque of 1240 in. lbs., compared

to less than 400 for a typical cordless drill of the same

voltage. But the more important difference between a

drill/driver and an impact driver is in the delivery. Unlike

a drill, an impact driver transfers high peak levels of

torque directly to the fastener, and very little to the

handle of the tool. Mechanically, the comparison is roughly

the same as driving a nail with a hammer versus pushing one

in with a rock.

In

terms of fastener driving speed and comfort, most impact

drivers will run circles around a cordless drill. But when

you're in the market for one, the unique qualities of

individual models are worth careful consideration. In actual

practice, the performance of the tool will depend on a number

of factors: motor efficiency, quality and design of the

impact mechanism, and the power and reliability of the

battery. Look for a built-in work area illuminating LED light

- a small amenity that you'll gain a big appreciation for

the first time you operate your impact driver inside an

upside-down boat hull or dark cabin.

Another important consideration is the battery system. As

may be common knowledge by now, lithium-ion batteries offer

several advantages over Ni-Cad or Ni-MH batteries (the other

two types available for cordless tools) including twice the

number of battery life cycles, greatly decreased

self-discharge when stored, less power drop-off toward the

end of the cycle, and best of all, no discharge

"memory", meaning that the batteries don't have

to be run down to nothing periodically for conditioning.

Along with that, they're much lighter than their

nickel-based counterparts and don't pose the

environmental problems on disposal.

If you are using a cordless drill to drive screws, switching

to an impact driver will have an immediate and marked effect

on your attitude toward fastening in general. That's no

exaggeration. In fact, using an impact driver for the first

time can be an almost eerie experience - screws slide in so

effortlessly; there's very little pressure required to

keep the tip of the driver engaged in a screw, and because

torque is transferred more directly to the fastener, very

little sensation of the handle of the tool wanting to twist

out of your grip.

For us boatbuilders who spend a fair amount of our time

driving screws and other fasteners, the payback in speed,

convenience, comfort and reduced fatigue you'll get from

an impact driver will make the investment feel like a

bargain.

Recent email:

Subject: 14' Driftboat

Date: 13 March 2009

My name is Mark Mariano, Jr. and I am currently building your

14' Driftboat. I am building it in my

carpentry class at the University of Montana, College of

Technology in Missoula, Montana. I am a first-time builder

and am a very lucky guy to be building my own boat for

college credit!

So far I

have built the hull and am now at the fiberglassing stage. I

am racing the clock to beat the spring runoff on the local

rivers and hope to have it on the water by the end of the

'08-'09 school year.

So far I

have built the hull and am now at the fiberglassing stage. I

am racing the clock to beat the spring runoff on the local

rivers and hope to have it on the water by the end of the

'08-'09 school year.

I would like to thank everyone that has posted on the Boatbuilder Forum and the Glen-L family

for their help and support so far. The project has stirred up

a lot of interest within the school and I'm sure that it

will not be the last Glen-L boat that is made in our shop. I

have told everyone about all the help and resources provided.

I will send more pictures as the project comes along.

-- Mark Mariano, Jr.

Missoula, Montana

Subject: Project Registration

Date: 20 March 2009

My name is Matthew Trent and I am building the Glen-L Fancy Free. I hope to name the boat after

my mother in honor of what must have been the most stressful

years of her life - my birth to graduation! I suppose the

name is up to the powers that be. Perhaps I should invest in

a sacrificial lamb and a really good bottle of rum! It

couldn't hurt.

I live in Tacoma, Washington and sail weekly on the Pacific

Northwest's biggest protected saltwater pond. That's

right; the good ole Puget Sound. You could spend a lifetime

gunkholing her shores and never see it all, though it's a

worthy enough mission objective to ensure many thousands of

hours at the till. Har..Har!

I recently retired from the Army and have chosen in sound

body and mind (if I can use the two statements in the same

sentence!) to build a boat myself. I have owned many old

Woodie's, but never delved any deeper than light

restoration. This project promises to be a deeply fulfilling

use of my newly acquired "freedom."

I currently have the hull constructed, and am in the process

of glassing the bottom. This Washington rain prolongs the

cure rate, but I hope to have her painted and righted by the

end of the month. It isn't a large percentage of the

build, but having gotten this far in just six weeks I feel

I'm well ahead of schedule.

-- Matthew Trent

Tacoma, Washington

Subject: Landlocked Boat in Missouri

Date: 16

March 2009

Date: 16

March 2009

Also I read all the WebLetters up to WL-106; will finish in the next week. Gayle, the Teleconference was great. Thanks to you all for the work to set it up

-- Brad Schiller, Builder in the corn

Council Bluffs, Iowa

Subject: Drift Boat

Date: 30 March 2009

I can't tell you how much fun we've had. We're considering making this "our thing" and wanted to thank you for your plans. We've been documenting our progress on the Drifter with pictures and would like to put them up on your site when we finish. We'd also like to do the same with our Stripper and whatever bigger model we move onto next.

Thanks. You all have a good one.

-- Douglas Rohde

Hermiston, Oregon

Subject: Thank You

Date: 18 March 2009

I have been very pleased with all the information and products (Minuet, Series 1000 Trailer plans, silicon-bronze screw kit for Minuet, Glen-L 17 plans - not yet built) your company has provided over the years.

Thank you for the truly unique service you provide.

-- Robert Zopp

Richardson, Texas

Subject: Build Your Dream Boat

Date: 15 March 2009

I enjoy your emails, and your “Family Atmosphere.” I think your father started a great company and it is fantastic that you are following in his foot steps.

Attached is a movie clip of me building the Power Skiff 14 (13’4" finished? It shrunk..

). I ordered the plans in December, 2008 and

was in the water by late February; the movie will show it all...

I hope you enjoy it.

). I ordered the plans in December, 2008 and

was in the water by late February; the movie will show it all...

I hope you enjoy it.

I built it mostly for the experience and I did learn a lot,

so I am now prepared for the next project. Probably a

restoration project of a larger sailboat, if I can find a

suitable boat.

Kind regards,

Bradenton, Florida

What Kind of Bait?

John went fishing one day but had no luck at all. He

noticed that another fisherman near him was catching

fish one after another. He had to know the secret.

He approached the other fisherman and said,

"Excuse me sir, but would you mind telling me

what sort of bait you are using?"

|

GLEN-L boats, of course

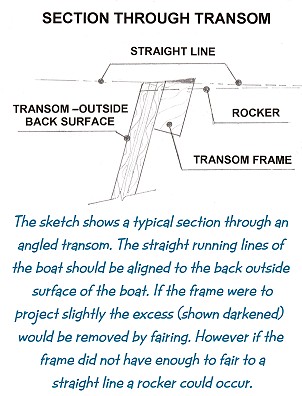

The sketch illustrates a common

"goof." The back outside surface of the

transom must be used to bring the transom bottom

surface up to a straight line in reference to the

frame members. The inner framework of the transom

must be level or slightly higher than the outside

surface for fairing. The sketch shows what can

happen If the transom is canted or at an angle to

the vertical. When the outside surface is not used

to bring it in correct alignment a rocker can result

when the area is faired.

The sketch illustrates a common

"goof." The back outside surface of the

transom must be used to bring the transom bottom

surface up to a straight line in reference to the

frame members. The inner framework of the transom

must be level or slightly higher than the outside

surface for fairing. The sketch shows what can

happen If the transom is canted or at an angle to

the vertical. When the outside surface is not used

to bring it in correct alignment a rocker can result

when the area is faired.