A place to share YOUR boat building story

Glen-L Marine Designs - 9152 Rosecrans Ave. - Bellflower, CA 90706

In this issue

In this issue

-

Beware of Hitch-Hikers

-

Glen-L Boatbuilder of the

Month

-

Building the True Grit by Ray

Macke

-

Designer's Notebook: Drilling

the Shaft Hole for an Inboard

-

The Mussels are Coming, The Mussels are

Coming by ArtDeco

-

Photos posted since the last

WebLetter...

-

West Coast Rendezvous of Glen-L Boatbuilders is Almost Here!

-

Shop Talk: Rip Sandpaper with

Precision

-

Recent email

-

Tool Usage

Dictionary

GLEN-L Update

Now that the holidays are behind us we're back with a new and (we hope) exciting WebLetter for you! We hope that you'll enjoy and maybe even learn something new by looking over this issue, and that many of you will be encouraged to come join us at the West Coast Rendezvous taking place in California this coming May.

Thanks to the tremendous contributions made by quite a few of our builders, Glen has in this issue written a very detailed and informative "Designer's Notebook" column on how to drill an accurate and effective Shaft Hole for your inboard design.

Of course, once again ArtDeco has written a very entertaining poem about a "muss-cular" subject that could affect us all. And Ray Macke has submitted another fabulous story of his boating and boatbuilding exploits.

Please continue to send in your emails, letters, stories, and photos to share with all of our readers so that every WebLetter will have something in it for everyone.

Until next month . . .

Editor

Beware of (These) Hitch-Hikers

DREISSENA BUGENSIS, DREISSENA

POLYMORPHA

(SAY THAT 3 TIMES FAST!)

Dreissena bugensis, better known as

Quagga mussels, and Dreissena polymorpha (a.k.a Zebra mussels) are destructive invasive

aquatic species that grow to about an inch in diameter.

Sometimes they are larger, sometimes they are microscopic.

These small, freshwater bivalve mollusks are triangular with

a ridge between the side and bottom. They have black, cream

or white bands, and often feature dark rings on the shell

almost like stripes.

polymorpha (a.k.a Zebra mussels) are destructive invasive

aquatic species that grow to about an inch in diameter.

Sometimes they are larger, sometimes they are microscopic.

These small, freshwater bivalve mollusks are triangular with

a ridge between the side and bottom. They have black, cream

or white bands, and often feature dark rings on the shell

almost like stripes.

Zebra and Quagga mussels are native to the Ukraine and

Russia. Zebra mussels were first discovered in the Great

Lakes in 1988, and a year later, Quagga mussels were

discovered in the same area. It is believed they arrived in

America via ballast water discharge.

Quagga/Zebra mussels can colonize on hulls, engines and

steering components of boats, other recreational equipment

and if left unchecked, can damage boat motors and restrict

cooling.

These hitch-hikers pose serious risks and costs to you as a

boat owner because they can:

Glen-L Boatbuilder of the Month

James Logan - Starpath 44

The SPIRIT, a Starpath 44, was completed and launched

in 2006.

The SPIRIT, a Starpath 44, was completed and launched

in 2006.

The vessel has been a great success. I am very pleased with

her performance under sail. We have had a chance to sail her

under light to moderate conditions up to 25 knots of wind and

are very satisfied.

The attached picture of SPIRIT under sail was taken

on August 16, 2009 about 2 miles offshore from Point Loma,

San Diego, California. She was doing 5 knots at about 40

degrees off the wind. Wind was about 10 knots. We were

running about 1200 square feet of sail.

Construction Photos

Project Registry

A Visit with James Logan before SPIRIT'S

Launch

Building the True Grit

by Ray Macke

Chapter 13 - Prep and Painting

Although my True Grit construction plan was to work

only during the cold winter months, the summer of 2009

brought about a bit of reality. All the main structure was

complete and interior work could begin. But I recognized

there were numerous items that needed to be completed for

work to progress in an orderly fashion. Things like through

the hulls for the bilge pumps, gas tank fills and water tank

fills needed to be added while they were easily accessible

from the interior. If I waited they would be inside cabinets

and much harder to reach. But their install would be much

cleaner if the exterior was painted as it eliminates masking

and time spent trying to paint around them. So it seemed

painting the exterior was next on a long but shrinking list of

things to do.

But this is where reality started to disrupt my building

plan. My large but totally un-insulated shop is not easy to

heat during the winter and holding the needed temperature for

painting would be a problem. I decided the only solution was

to have the painting completed by late fall. This meant I

would have to work through the summer to get it done. Not

what I had planned as when the weather is warm I would rather

be boating, riding my motorcycle or anything outdoors. Not

working in the shop. But if I were to wait for winter to

begin the process several months would be lost waiting for

mild enough spring weather.

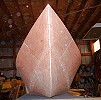

And so it began. Building a 27’ boat is a substantial

undertaking but it tends to grow slowly and the dimensions

become somewhat muted. But the true size of the beast

suddenly becomes apparent when you start sanding. And

sanding. And sanding.

Designer's Notebook: Drilling the Shaft Hole for an Inboard

|

The Mussels are Coming, The Mussels are ComingNasty critters in our watersOnly fresh waters but beware They're coming and spreading You had better take care The name sounds strange Dreissena Bugensis That's the Quagga mussel And there're no defenses Dresissnena Polymorpha Is that pesky Zebra mussel That little bugger's giving me A real pain in my bustle Their habits are bad They eat up the food That all small fish eat And that isn't good They grow in big clumps On motors and pipes Clogging and choking And blocking, Yipes! Some states and counties Are doing their best To prevent the spread Of these two little pests Be ready for inspections The standards are high To launch, your boat must Be clean, drained and dry It's a hassle for sure and Of course, it's not free The launch fees are doubled That's really bugging me So take note, my friend Unless your boat's been traded Watch out for the mussels Cause we're being invaded! -ArtDeco |

Photos posted since the last WebLetter... |

West Coast Rendezvous of Glen-L Boatbuilders

Join us for another get-together organized by the members of the Glen-L Boatbuilder Forum. Bring your boat whether you built it yourself, or it's in process or even a manufactured boat. The more the merrier!

So far, we have people bringing the following boats:

- Monaco

- Wee Hunk

- Flying Saucer

- 1919 Navy Launch

- A-Lure

- 2 Zip Runabouts

- Squirt

To learn more or just join in the coversation visit the Glen-L Boatbuilder Forum

West Coast Rendezvous of Glen-L Boatbuilders

Sunday, May 2, 2010

Sugar Barge Resort & Marina

1440 Sugar Barge Road

Bethel Island, California

|

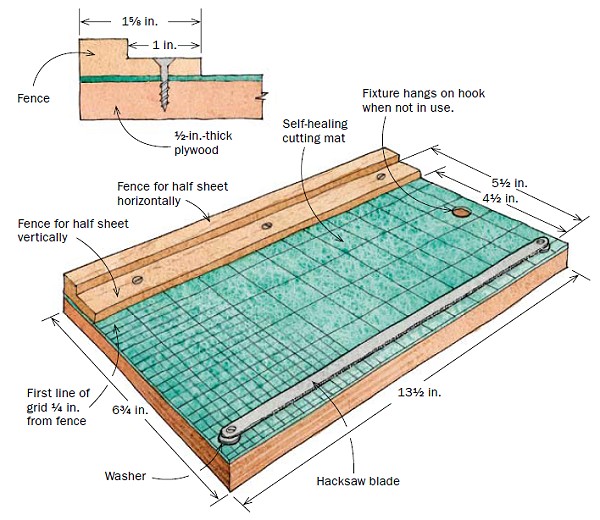

Shop Talk: Rip Sandpaper to Size with Precision

Building a boat incorporates lots of curves, some of which may require some sanding. To help use expensive sandpaper efficiently, you can build this fixture, which will allow you to rip sandpaper sheets to any size quickly and easily, with little waste.

You may find this to be one of the most frequently used fixtures in your workshop. Michael Fortune, of Lakefield, Ontario, Canada is on his second - the first one gave out after 30 years of use.

Recent email:

Subject: It Floats!

I just finished building your Sea Kayak Two and good news, it

floats!

I just finished building your Sea Kayak Two and good news, it

floats!

It was my first time working with the "stitch and glue" method of

construction and by the end of the project, it was a

snap!

Thanks for the great plans and I am in receipt of your Lo Voltage plans for my next build.

-- Aaron Pufal

Plantation, Florida

Subject: Zip in Brazil

Thanks.

-- Amaurí Cascapera

Sao Paulo, Brazil

Subject: It's Never Too Late

I bought these plans from you in

the 80's and finally built your Class AB boat.

I bought these plans from you in

the 80's and finally built your Class AB boat.

I actually built it as a model in 1:12 scale and it a good

learning experience for when I finally build the full size

boat.

-- Tom Wysocki

Subject: WebLetter 118

I was very pleased to see my golden prose published for all to see in your new newsletter (ZIP-Builder's Diary). Congrats on putting it together so handsomely. The little bit of editing you did was certainly understandable.Your web site is really quite good - lots of depth and content, but still easy to navigate. As a former computer geek I can appreciate a good site like yours. It's good to know there's a resource like you guys out there.

-- Dave Coleman

Castro Valley, California

Subject: Thanks!

I purchased plans from you for the Sweet Caroline around 1990...built it...registered it in Massachusetts in 1994...it has been the best ever since!Sank in a hurricane...survived...has taken my daughters and now my grand children up harbor every year...

Thank you for providing me with the detailed instructions to build this incredible boat. It has been moored in Nantucket harbor for 14 going on 15 years.

Yes. It has totally changed my life...as anyone else will acknowledge who has built their dream. I thank you forever! Always!

-- Charles Dunton

Nantucket, Massaachusetts

Subject: Squirt

I just thought I would just send you some more pictures from another satisfied customer. As a teenager, I purchased my first boat which happened to be a Glen-L Flying Saucer. I outfitted it with a 1967 33hp Evinrude Ski Twin and had endless enjoyment with my buddies learning to waterski and just plain messing around at Elk Lake near Victoria, British Columbia. Now

that I am a father, I decided to try and give my son the same

experience. We purchased plans to your Squirt design a couple of Christmases ago

and built her over the winter in the garage. We rebuilt an old

seized 1973 9.5hp Johnson outboard for power and launched her at

Canim Lake in the interior of British Columbia, where she still

resides today.

Now

that I am a father, I decided to try and give my son the same

experience. We purchased plans to your Squirt design a couple of Christmases ago

and built her over the winter in the garage. We rebuilt an old

seized 1973 9.5hp Johnson outboard for power and launched her at

Canim Lake in the interior of British Columbia, where she still

resides today.I have attached a few pictures to illustrate the final product. As you can see from the expressions on my son's face, the project was a great success!

Thanks again,

-- Bruce Richmond

North Saanich, British Columbia, Canada

Subject: Barrelback 19' Project

George and I began building the Barrelback back in December of 2007. We discussed starting with a smaller plywood construction boat to gain some building experience first, but decided to jump right in and build the boat we both wanted.Building goes in spurts as we generally only work on it weekends during the winter months after the hunting season ends in November. After the holidays, most every Saturday and Sunday we work on it together while the wives are busy playing Scrabble and drinking wine in front of the fire.

So far we are about 80% finished fairing and hope to start the Cold-Mold planking in about two weeks. Our goal for this winter is to complete the outside of the hull so we can flip it by time the boating season begins here in May. We are planning on using a 4.3 Liter V6 for power.

George and I are both very interested in speaking with others who are either building or have built the Barrelback as we have many questions. We also have learned many things that might be helpful to others.

-- Mike Clem & George Portfleet

Grand Rapids, Michigan

Subject: A Winner!

A stretched (21 ft) Tahoe completed in July of '07. Entered in Traverse City Michigan Boat Show and the Hessel, Michigan boat show 1 week later. Won best contemporary classic in Traverse and second place contemporary classic in Hessel.

Where do I go from here?

-- Lee Rea

Lowell, Michigan

Tool Usage Dictionary

|

GLEN-L boats, of course