A place to share YOUR boat building story

Glen-L Marine Designs - 9152 Rosecrans Ave. - Bellflower, CA 90706

In this issue

In this issue

-

Dreams Realized by Gayle

Brantuk

-

Boats on a Lake by Markus

Hosseini

-

My Tubby Tug Build by Doug

Wade

-

Designer's Notebook: Strengthen

Your Bottom?

-

Sale-ing by ArtDeco

-

Photos posted since the last

WebLetter...

-

Build a Boat in a Week by Bob

Spiess

-

Shop Talk: Savy Storage for Small

Stuff

-

Recent email

-

The Captain's

Parrot

GLEN-L Update

- This is the first WebLetter since Gayle and I returned from the 2010 Gathering of Glen-L Boatbuilders, or "G4" as the regular attendees have dubbed it. I honestly can't adequately express just how interesting and how much FUN these Gatherings are. And it's all due to the wonderful, personable and generous volunteers who populate the Glen-L Boatbuilder Forum who have taken it upon themselves to plan, organize and execute on their own this valuable event each year. If you made it to G4, be sure and log onto the Forum and express your thanks to the organizers, and check out the plans for G5 - it looks like it's shaping up to be another spectacular time for all who can join in on the fun!

- Did you like this WebLetter? The WebLetter is prepared between other responsibilities and the finished product depends a lot on input from Glen-L builders. If you have a story to tell, don't be bashful, our readers are interested in your boatbuilding project. Don't worry about grammar, spelling, etc. Three people proofread the WebLetter and we often make corrections. Email your story, attach photos with captions. Seeing other projects is a great help to builders. Thanks to those of you who contributed to this WebLetter.

- A reminder... Christmas is coming and friends and family would like to get you something you REALLY want. You might want to print out some pages from the Glen-L Online Store and leave them laying around, with appropriate circles and arrows... just a thought.

Until next month . . .

Editor

Dreams Realized

by Gayle Brantuk

FOURTH GATHERING OF GLEN-L BOATBUILDERS

Pride of achievement is the true

reward of building a boat. It's evident by the look on

the faces of every builder at each Gathering we've had

for the past four years.

This pride comes from a job well done, from a goal achieved,

a dream realized. The double-takes they get on the water and

the folks asking "how old is your boat? These

experiences are what make it all worthwhile. And the guys I

talked to say it was worth every minute.

September 24-26 was the fourth Gathering of Boatbuilders organized by

the members of the Glen-L Boatbuilder Forum. Each year I write

about this event and how wonderful it was, how it gets better

each year, about all the beautiful boats and so on. All this

is true, but there's a much deeper thread to G4 as

it's now affectionately called.

It's not just about the beautiful boats that guys have

built with Glen-L boat plans, or having fun riding in those

boats, the wonderful people that attend or the great

food. It's about people

living and fulfilling their dreams. And there's always a

story behind the boat, and to me that's the best part.

Rory Hamilton is a third generation Glen-L boat builder. His

inspiration is his grandfather who built the Sea Knight and he is determined to build

a boat just like Grandpa's. He brought a photo album to

the Gathering showing photos of his family's boats and

some of the start of his own project. I could feel Rory's

passion. This is more than just a boat to build. He's

building his dream and carrying on his family's

tradition. And his wife Kristen was right there with him

providing encouragement.

It's about people

living and fulfilling their dreams. And there's always a

story behind the boat, and to me that's the best part.

Rory Hamilton is a third generation Glen-L boat builder. His

inspiration is his grandfather who built the Sea Knight and he is determined to build

a boat just like Grandpa's. He brought a photo album to

the Gathering showing photos of his family's boats and

some of the start of his own project. I could feel Rory's

passion. This is more than just a boat to build. He's

building his dream and carrying on his family's

tradition. And his wife Kristen was right there with him

providing encouragement.

Then there was Mary and Bernard. This couple came from

Wisconsin where they own and run a resort. They closed down

the resort and came to the Gathering for the first time. On

Saturday, when we got all of the boats out on the water so we

could get some good video, Mary and Bernard were standing on

the docks wondering what they should do. Bill Edmundson told

them they were welcome to hop in the back of his 24' Tahoe with us.

We were out on the water for close

to an hour with about 30 boats running and having a great

time. I looked back at Mary and Bernard and with a huge smile

and two thumbs up, Mary said "I'm living my dream

right here in this boat".

We were out on the water for close

to an hour with about 30 boats running and having a great

time. I looked back at Mary and Bernard and with a huge smile

and two thumbs up, Mary said "I'm living my dream

right here in this boat".

Seriously, how many people get to ride in a 24' mahogany

runabout that was built by hand, not in a factory, but by the

guy driving… with his own two hands… with the

sweat of his brow? It's an awesome experience.

And then there's Dave Lott who recently completed

building his Riviera, a 20' classic mahogany

runabout. Dave built this beautiful boat in only 11 months

and it's truly impressive. The story behind his boat is

lengthy and detailed on his blog, but the bottom line is that

building his boat was an opportunity to share his Christian

faith and testimony.

I also had an opportunity to take a ride in Gary

Steinkamp's Missile  which is a 16' inboard speed

boat. On the dash of Gary's boat is a brass plaque that

reads "Gene Steinkamp - May his spirit be with us".

Gene is Gary's brother who was in a wheelchair for 50

years because of polio from which he finally passed. He

helped Gary build the Missile… you can imagine that

this is more than just a "boat" to Gary.

which is a 16' inboard speed

boat. On the dash of Gary's boat is a brass plaque that

reads "Gene Steinkamp - May his spirit be with us".

Gene is Gary's brother who was in a wheelchair for 50

years because of polio from which he finally passed. He

helped Gary build the Missile… you can imagine that

this is more than just a "boat" to Gary.

Who can forget young 12-year old

Collin who raced his 10' Super Spartan up and down the lake all

weekend? That boy handles his boat like a pro and had a ton

of fun using it. I even understand he's quite a captain

with the bigger boats as well.

Who can forget young 12-year old

Collin who raced his 10' Super Spartan up and down the lake all

weekend? That boy handles his boat like a pro and had a ton

of fun using it. I even understand he's quite a captain

with the bigger boats as well.

For years, many of our WebLetter subscribers followed the stories of Ray Macke and his adventures

in his Cabin Skiff. Ray has (so far) logged over

27,000 miles and 1587 hours on his 16' Skiff traveling

various intercoastal waterways. For G4, Ray brought his new

boat, the 27' True Grit that he's named

"SeaQuinn". We've watched Ray's build

online and know that his wife is much happier with a larger

boat with better accommodations. This isn't just a boat -

this is Ray and Vickie's transport to worlds unknown, to

adventures that await, to deepening the bonds of their

marriage.

And of course,

there's Chris who came to his first Gathering last year

with his wife Heather along with photos of the beginning of

his boat. Chris is one of our younger builders and this year

he brought his finished Zip which is one of our most popular

14' runabout designs. Chris gave ride after ride in his

pride and joy which he named "First Born". You

could just feel the well-earned pride this young man has. He

and Heather even took photos with Santa hats on for their

Christmas cards.

Those are just some of the stories. There are many more and

that's to me one of the best things about our Gatherings;

getting to know the people behind the boats. These folks are

family to us here at Glen-L and we treasure the friendships

we are building.

These boatbuilders have much to be proud of. They started

and finished building a boat that they can be truly proud of.

They had a goal, a dream and they saw it through to

completion.

All of us at Glen-L are grateful for each of you who

attended G4 and thank you for making this event the highlight

of our year. If you weren't able to make it to this

year's Gathering, we urge you to make it to G5 because you'll kick yourself if

you don't! See you next year!

Editor's Note: See more from Gayle in the Glen-L BLOG.

Boats on a Lake

by Markus Hosseini, Roving reporter

Lake Oswego, Oregon

LAKE OSWEGO – The Oswego Heritage Council will

host its 11th annual Collector Car and Classic Boat Show

Sunday at George Rogers Park. An estimated 250 classics,

rods, sports and special interest cars and 40 classic boats

will be on display from 10 a.m. to 3 p.m. on the corner of

Ladd and South State streets. Boats also will be on display

at the nearby Lake Oswego Corporation Docks on State

Street.

My plan was that 2010 would be the

year that I made it to the Port Townsend Wooden Boat Show.

I'd been online to see about hotels and such and printed

out information on likely's. But then it turned out that

the most practical time to visit relatives on the East coat

would be during the event, so another year missed. I grumbled

about this to my wife, who said, "Why not go to the Lake

Oswego Boat Show, it's this week?" I didn't have

great expectations, but decided, "why not".

As it turned out, I was pleasantly surprised. There were

over 40 classic boats on display in a beautiful setting, we

had a wonderful day looking at classic wooden boats. Because

I know that readers of the Glen-L WebLetter love to look at

wooden boats, I took lots of pictures. There were no

Glen-L's among those on display, but these classic

originals should provide lots of ideas for those who are

building their own “classics”.

My Tubby Tug Build

by Doug Wade, Toronto, Canada

I first began building my Glen-L Tubby Tug early in the spring of 2008

when I turned the plans into a kit by cutting out every piece

that I could. Other projects restricted Tubby Tug building to

the winters.

During the winter of

2008 - 09 I insulated a thirteen and a half foot by nine and

a half foot portion of my small single car garage and this

area became my boat shed. I completed the hull and painted

the exterior that winter. I also built the front of the pilot

house and used a router to make hawse pipe covers and the

ship's wheel.

During the winter of

2008 - 09 I insulated a thirteen and a half foot by nine and

a half foot portion of my small single car garage and this

area became my boat shed. I completed the hull and painted

the exterior that winter. I also built the front of the pilot

house and used a router to make hawse pipe covers and the

ship's wheel.

Building resumed November 2009; with seven foot headroom in

my boat shed I had to build the pilot house in the boat

because there was not enough room to lift the completed pilot

house into the boat. The boat was completed the end of

February 2010. I enjoyed every hour spent on this project and

have no idea how many hundreds of hours I spent on it.

My Tubby Tug has full running lights and a solar panel to

keep the battery topped up. The steering is homemade old

fashion drum and cable. To add play value a fire monitor is

powered with a high pressure 12 volt pump. I used Interlux

Brightsides paint, Maas epoxies and marine ply bought at

Noah's Marine in Toronto Ontario.

This was my first boat building exercise and one of the many

pleasures was the many things I had to learn such as the fact

that sand paper is a cutting tool and when dull it should be

discarded. Building a boat is easily within the skill level

of most people if it is simply viewed as an endless list of

doable tasks.

My wife fears that I am now an addicted boat builder and I

already have plans for two more boats. My problem is a lack

of space for storage of completed toys.

Editor's Note:

See photos of the custom touches Doug made

to his Tuggy Tub in Customer Photos.

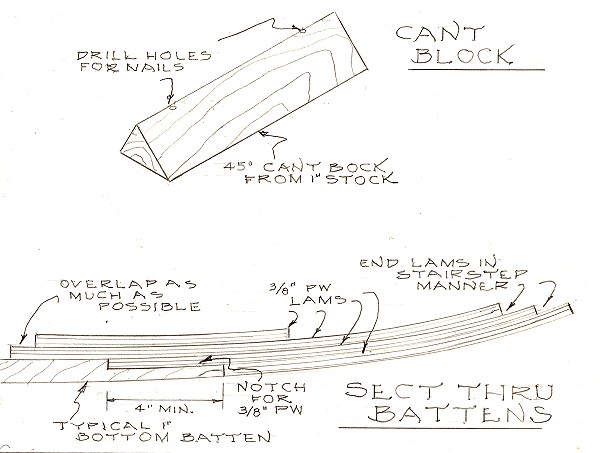

Designer's Notebook: Strengthen Your Bottom?

|

Sale-ingSummertime is nearly overEnd of all the boating fun Though I know it’s not forever I’m still feeling kind of glum But now it’s time for planning Winter’s boat building work Doing boat mods and upgrades Those are some of winter’s perks Stores change their inventory Shifting space to winter things Summer items are reduced That’s a good that winter brings Time to look for boating bargains Watch for end-of-summer sales Get epoxy, paint, tools and ply Plans for new boat building tales Keep your boating spirit up Do the work you’ve put on hold If your own weather permits Start that new boat, be bold! So, my friend, as the story goes Tote that barge and lift that bale But keep your eyes open ‘cause Boat stuff’s ON-SALE! -ArtDeco |

Photos posted since the last WebLetter... |

Build a Boat in a Week

by Bob Spiess

Well my summer boat building

project is over and it was

a complete success. I was a camp counselor and did a

"Build a Boat in a Week" class with 80% senior high

school girls in the class (it can be done). They did a great

job and are very proud of their accomplishment. I finally

chose the Glen-L Imp (the class named it the

"Squirt") after talking with you as it had real

style, good lines, and would make the class proud. The girls

learned a lot about epoxy, fasteners, power tools, building

frames, etc, and boats in general. What excitement at the

launch ceremony at the end of the week when it slid into the

water.

and it was

a complete success. I was a camp counselor and did a

"Build a Boat in a Week" class with 80% senior high

school girls in the class (it can be done). They did a great

job and are very proud of their accomplishment. I finally

chose the Glen-L Imp (the class named it the

"Squirt") after talking with you as it had real

style, good lines, and would make the class proud. The girls

learned a lot about epoxy, fasteners, power tools, building

frames, etc, and boats in general. What excitement at the

launch ceremony at the end of the week when it slid into the

water.

I promised the class that I would bring the boat to the

Mystic Seaport "Antique Marine Engine Exposition"

August 21-22 with my 1939 Elto "Handitwin" on the

stern. That all happened last weekend with total success.

There were 296 exhibits at the Seaport and Squirt was in

front of them all. In other words, the public needed to pass

Squirt and me to get to see everything else.

I have never talked with so many people for so many hours in

a long time. Your IMP was very popular and Glen-L was given

full credit for the design. Some people were surprised to

know that Glen-L was still in business and www.glen-l.com was a very popular address

for me to give out. We had many teachers (especially shop

teachers) stop by and they were very pleased to know that

some people are still interested in seeing young folks learn

to build with their hands. Many boat lovers commented on the

excellent design of IMP and wanted to know if this boat was

for sale.

The class actually donated the boat to the camp for use as a

trainer in rowing and general boating safety for the younger

age children in years to come. I have included some pictures

and posters for you. I have enjoyed discussing this project

with you all at Glen-L and thank you for all the help and

plans.

Safe boating,

--- Bob

you can do it!" |

Shop Talk: Savy Storage for Small Stuff

STORAGE POCKETS FOR SKINNY THINGS

Saw off short pieces of 1 1/2", 2" or 3" PVC plumbing pipe with 45-degree angles on one end.

Screw them to a board to hold paintbrushes, pencils, stir sticks and just about any other narrow paraphernalia in your garage or workshop.

Mount them by drilling a 1/4-in. hole in the angled end, and then drive a 1-5/8-in. drywall screw through the hole into the board.

CANNERY ROW HARDWARE STORAGE

Don't recycle those steel or aluminum cans quite yet. Set

aside a few months’ worth of fruit and coffee cans and

put these cannery rows to work organizing all of the small

hardware in your shop. All you need are some homemade wood

clips and a chunk of 3/4-in. plywood screwed to a wall.

To make the clips, rip a 3/4-in.-thick board into

1-3/8-in.-wide strips. Saw or rout a 3/8-in. x 1/4-in. rabbet

along one edge. Drill 1/8-in. screw holes every 3/4 in. and

then cut off 3/4-in.-wide clips. To mount the clips and cans

on the plywood, screw on a clip, notch end down, then set a

can on the clip and screw on a second clip overlapping the

can's rim about 1/4 in.

That’s it! Keep adding clips and cans until every

screw, bolt, nail and nut has a can to call home. Label the

cans, and keep one loaded with surplus clips and screws for

adding on.

Recent email:

Subject: Another TNT from the plans by Glen-L

I recently finished

this TNT. I changed the deck a bit to give it

a more sporty look. The boat took me exactly two months from

start to finish working evenings and weekends.

I recently finished

this TNT. I changed the deck a bit to give it

a more sporty look. The boat took me exactly two months from

start to finish working evenings and weekends.

I have never built a boat before and I am not a woodworker

so if I can do this, anyone can.

-- Bill Snyder

Greeneville, Tennessee

Subject: Acapulco Camper

Hi Guys. Thirty five

years ago I built one of your campers and put it on a Ford

f100 truck. During the last two months I built your Acapulco to fit on my Ford Falcon

trayback ute.

Hi Guys. Thirty five

years ago I built one of your campers and put it on a Ford

f100 truck. During the last two months I built your Acapulco to fit on my Ford Falcon

trayback ute.

I modified the front to give it a different look and also

modified it to fit on the trayback.

What do you think?

-- Bob Hodkinson

Yanderra, Australia

P.S. I am 68 years old.

Subject: Fisherman

The previous owner had

put a false floor in it which did not allow any possibility of

getting water from under the floorboard, which caused some

problems. I removed the floor and took the boat to bare wood

inside and out. I had to do some improvising on the bottom at

the transom, but the end product is well worth it.

The previous owner had

put a false floor in it which did not allow any possibility of

getting water from under the floorboard, which caused some

problems. I removed the floor and took the boat to bare wood

inside and out. I had to do some improvising on the bottom at

the transom, but the end product is well worth it.I have run the boat with a 1950 Mercury KG7, a 1951 Mercury KG4, a 1952 Mercury KH7, and a 1953 Mercury Mark 20. The GPS showed 28 MPH with the KH7, and the boat handles well. I showed this boat at the Chicago Boat and Travel Show this year, and heard a lot of nice comments.

-- Dave Wilson

Subject: Thank you

Have a nice week

-- Joel Bouchard

Napierville, Quebec, Canada

Subject: Boat Plan Puzzlement

Still scratching my head, I attached the keel, which tied the stem to the transom across all the forms. At this point I was taking it all on faith, hoping the written instructions were going to work.

After that point, I sat down and looked at it for awhile. (I read Payson's book on Instant Boats, and he finds a 'thinking chair' to be an essential part of the shop. Now I know what he meant.) After some time in the chair looking from the plans to the barely attached pieces on the shop floor in front of me, the light clicked and I could see how the rest had to fit together.

The rest of the inverted construction phase went pretty well. The part I most feared, getting the side planking to meet on the bow, came together just fine. The gap at the plywood's end ranged from zero to 1/8". The plywood screwed down to the stem itself tight with no odd bends or twists at all.

I just put the fiberglass on the bottom this morning. I have no doubt I will be able to finish this project in good order. My next boat is going to be a Minuet. No straight lines anywhere, which is what prompted me to try something simpler (and I wanted a fishing boat anyway).

If the Minuet turns out to not be big enough, I'll build a Fancy Free, or a similar boat.

On that subject, others who favor stitch & glue have called the chine-logs and frame system old-fashioned and out of date. You carry plans for both construction methods. It might be useful if someday you could go through the advantages and disadvantages for both methods. The only stitch & glue boat I'm familiar with was a nightmare of sanding tight internal curves smooth enough to have a hope of getting the fiberglass tape to lay down flat. But the chine logs that were supposed to be oh-so-hard to cut correctly took about 30 seconds each on the table saw. The area that didn't come out quite the way I thought it should took another minute on each side with a power plane. "This is supposed to be difficult?" I thought. Quite a change from that first "holy cow!" moment.

-- Michael Spangler

Soap Lake, Wshington

The Captain's Parrot

A magician was working on a cruise ship in the

Caribbean. The audience would be different each

week, so the magician allowed himself to do the same

tricks over and over again. There was only one

problem; the captain's parrot saw the shows each

week and began to understand how the magician

performed every trick. |

GLEN-L boats, of course