Rigging Small Sailboats

Chapter 10

.....daggerboards and centerboards

Page 2A centerboard on the other hand is hinged at its forward portion on a CENTERBOARD PIN. The centerboard pin is usually a bolt or rod about which the centerboard pivots up or down in the CENTERBOARD TRUNK (see Fig. 10-1). The centerboard trunk is similar in function to the daggerboard trunk. However, with a centerboard, it remains in the boat at all times in its trunk, while the daggerboard is removable through the top of the daggerboard trunk. Whereas the daggerboard moves up and down vertically in the slot of the daggerboard trunk, the centerboard "swings" about the centerboard pin. Because it can swing, the position of the centerboard can be varied to suit different courses of sailing, and changes in the loading and balance of the hull. From this standpoint, a centerboard is more efficient than a daggerboard. However, the slot for the centerboard where it passes through the bottom of the boat must necessarily be longer than for a daggerboard, and this adds to the resistance of the hull thereby slowing the boat down somewhat. One drawback of daggerboards is that should the boat sail into shallow waters or accidentally come up onto a beach, the daggerboard will not pivot back and up into the trunk as will a centerboard. The damage to the boat in such an encounter could be extensive, whereas with a centerboard, it would pivot back and up into the trunk with probably no damage at all.

When daggerboards or centerboards are made from wood, they have a tendency to float up out of the water just like a wood rudder. There are several ways to prevent this. Naturally, the board could be made from metal (aluminum or steel) or fiberglass, but this is not recommended unless the boat is originally equipped this way, or the designer specifies it. With daggerboards, spring stainless steel "clips" are available, which fit onto the board making the fit so tight in the trunk that the board cannot float up. Another method is to use an elastic "shock cord" across the top of the trunk slot secured at each end to screw eyes each side of the trunk. With both types of board, a removable "pin" can be used through the trunk sides and board that will "lock" the board in position. The boat shown in Fig. 6-8 features such a pin for the daggerboard trunk. By providing a series of holes in the board, the pin arrangement could be used to lock the board in various positions to suit sailing conditions. On centerboards of wood, a common method is to put a weight on the board. This can be a lead weight built right into a hole in the board, or a specially fabricated casting designed to fit the bottom of the board. The weight will pull the board down in position and then a pin arrangement can be used to lock the board in position.

Daggerboards are simpler in nature than centerboards, and therefore require few if any fittings other than those described above. Centerboards, however, can get more complex, especially the bigger the board gets in size and weight. The line used to raise and lower the centerboard is known as the CENTERBOARD PENNANT. On lightweight boards, the line may be attached by a knot through a hole in the board, and lead to a cleat somewhere on the trunk or hull structure. On heavier boards, the centerboard pennant can be rigged in a tackle arrangement to decrease the effort required to raise the centerboard. Pulleys or sheaves can be fastened to the centerboard and/or to the trunk to come up with the proper tackle.

On many of the trailerable cruising sailboats from about 17' in length and up, the centerboard is often a piece of steel plate or even a casting of steel or lead. Sometimes the latter are referred to as "retractable keels" because they also add to the stability of the boat. In either case, the weight of the unit is often such that a tackle will not be practical. When this is the case, a winch is used with a wire rope pennant to raise and lower the centerboard. The winch is best a two-way type with positive ratchet action on both the "down" and "up" directions. Worm-gear winches are available for use on boat trailers that are suitable for centerboard use, as are more deluxe types especially designed for centerboard use. All components used in such an installation should be of extra heavy duty and arranged so no jamming or fouling of the gear will result in use.

As noted previously, the centerboard or daggerboard trunk helps keep water out of the boat. This means that no holes or leaks should be permitted in the trunks AT LEAST BELOW THE WATERLINE. Sometimes this is a problem with centerboard trunks, especially at the centerboard pin. The centerboard is constantly "working" and causing stress on the pin that tends to loosen and let water seep into the boat. There are so many variations in the design of centerboard pin mechanisms (probably in an attempt to make a good one that won't leak) that it is not possible to specify a "cure-all" which will work in all cases. If the pin area is leaking, check to make sure that the bolt is tight, and if it has worked to where it fits too loosely in the hole, it should be replaced with a larger pin. Also check the gaskets, if so equipped, to see that they are in good condition, and replace if necessary. The structure of the centerboard trunk should be checked to see that all members are tight and well fastened. Sometimes a leaking pin is the result of a weakened trunk structure. If this is the case, repairs or replacement of structural members may be in order. Sometimes a little fiberglass tape and resin can work wonders in patching up leaks and reinforcing weak members, but make sure the areas to be fiberglassed are clean and dry first. Because the inside of the trunks will not be accessible after assembly, it is advisable to fiberglass the inside prior to assembly to seal the trunk and protect against abrasion by the board.

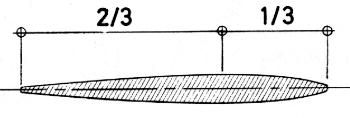

In use of the boat, sometimes there will be a vibration or "chatter," especially noticeable when the boat is moving along at top speed. This chatter is usually caused by an unfair centerboard or daggerboard, and sometimes an unfair rudder. What this means is that the edges and general sectional shape through the board have not been finished correctly. Obviously a board with a square edge forward or aft will not go through the water as effectively as a board with edges that are shaped or "faired." With sheet metal centerboards or daggerboards, about the only fairing that can be done is to radius the edges. If wood is used, a better "shape" can be incorporated. One method of fairing a wood board that gives good all around results is shown in Fig. 10-2. While very fine edges give least resistance, it is best not to make them "razor sharp" because they damage too easily in use. It is possible to build up the correct "shape" to any board by using foam shaped to suit and covered with fiberglass. If fiberglassing the outside of the hull, it is best to tuck fiberglass cloth into the trunk to protect the exposed plywood edge.

FIG. 10-2 - A section through a "faired" wood daggerboard. The same principle can be applied to rudders and centerboards. Note that the thickest part is located approximately 1/3 the width of the board aft of the forward or leading edge. Edges should be radiused slightly to prevent damage. |

With daggerboards that tend to bind or jam in use, a little paraffin will usually smooth things out. Sometimes the board will warp or the slot will not be quite the same shape as the board. This may require reshaping or replacing the board. Sometimes the board will fit too loosely in the slot. This will cause working at the pin on centerboards, and sometimes banging from side to side. Small blocks or metal angles can be used to make the fit at the slot tighter. Some device is often provided, especially with steel centerboards, to limit the forward travel of the centerboard to keep it from banging against the forward portion of the centerboard trunk. This is a good idea because pennants sometimes break, or a lock pin will fail, and the board will fall forward at a crashing speed.