On the Mark: Making Improvements

Continued...

A few more adjustments to size and shape and the bottom is ready to be fitted. The square is used to show where the front of the bottom panel will need to be. It looks nice when aligned as shown.

Several passes are needed to get the fit right as everything is curved and none of the hull joints are at right angles. It is easy to trim the foam core to fit. It is more forgiving than the 6mm Okoume plywood used for the actual holders.

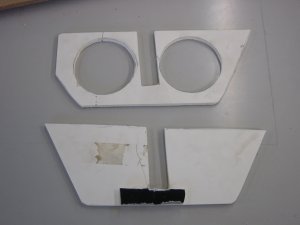

This photo shows the first test piece and the second. The second piece cracked during fitting and a glue block was tacked in place with thickened super glue.

The foam pieces are traced onto the plywood and then it is cut out. The edges are rounded over.

This photo shows the holder pieces in place, ready to be epoxied into position. The can fits comfortably and cannot bounce or slide out.

The pieces were epoxied in place and fillets of epoxy fair out the transitions. The pieces are a snug fit so no fasteners or clamps were required. Small blocks of wood covered with tape were placed under the bottom piece to temporarily hold it in alignment.

Finished photo. This shows it in place after epoxy and 3 coats of varnish.

More fins

The other improvement was to add two more skid fins. I had put one on initially. When cornering at slow speeds or when pulling a tube the bow of the boat would slip sideways. It did not always "hook up" with the water. High speed handling was not a problem, but slow speed and returning to a downed skier or tossed tube rider needed some help. We frequently pull a double tube and if one rider is out it was always hard to circle back to the one in the water. The extra drag made sharp slow speed turns difficult.

Competition ski boats have a basically similar hull design to the Riviera and typically have 3 fins. This is to improve tracking when pulling a slalom skier. The fins are below the front of the engine and pylon. We do not yet have a pylon, but the fins are basically in the same relative position. They are approximately 1" apart; the forward most fin straddles the frame in front of the engine.

The fins used are the Glen-L (#14-295) V-base bronze fins. They are raked backwards so that hopefully the boat will ride up over obstacles rather than destroying the fins. I through-bolted them. Many others recommend that you simply screw them in and allow them to be ripped off in case of collision rather than damage the hull. I am afraid that the force and pounding will eventually loosen screws and allow water into the interior of the hull and rot to start. Besides, if you are going fast enough to rip the fins off when you hit something, what becomes of the drive shaft, strut, prop and rudder? They are next in line.

The through-bolt holes are epoxied with 2-3 coats to ensure that the wood is completely sealed. I cut down a foam brush to allow it to fit in the holes. The fins are then though-bolted and bedded in 5200. More 5200 is used under the washers on the top to ensure a water tight fit.

The forward fin did have less of a vee than the hull. The fin flanges do not bend and I did not want to cut into the bottom of the hull. This meant that the outer edges of the fins need to be shimmed by ~2mm. I used thickened epoxy along the outer edges of the fin to take up the space. I mixed the epoxy with silica and set it aside until it started to thicken. It was ready for assembly when it had a puttylike consistency. We then bolted the fin in place (yes, with the wet epoxy and 5200 - it was messy). The bolts were slowly snugged up until the fin was in proper alignment. The squeeze-out was cleaned then cleaned off. The epoxy "shims" now give a firm mount for the fin and do not allow it to rock on the hull.

After launching, we immediately noticed the improvement in handling. Cornering is much better, and sharper. It is now possible to do a 25 to 20 foot diameter circle in a power turn! Picking up a lost tube rider is now much easier. Tracking with skiers and boarders seems better as well.

My wife definitely appreciated the improved turn around time last weekend when I was trying to learn to wakeboard. With 25 starts in one afternoon, fast pickups helped a lot. Yes, I was quite sore afterward but I wanted to figure out how I actually got up on the 3rd try. The learning curve is very odd, all of sudden you are up on top of the water trying both to figure out how you actually got up there and also how to steer the darn thing. Today we were out again and I think I finally have the fundamentals figured out.

We are very pleased to have Mark sharing his expertise with his fellow boat builders. If you would like to comment on this article to Mark, he can be reached at "builders at bronkalla.com". Replace the at with @. (Just trying to dodge a few spammers). See Mark's great web site for information on his Riviera project.