|

|

|

|

Michael Dawson

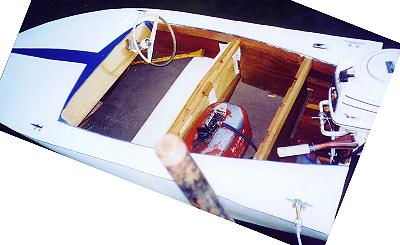

Making Glen-L Squirt

Sep 22

I'm done. I finished the boat the second week in August. My sister and her

kids were coming for two weeks at the cottage so I wanted it done by then. The

launch was an exciting time. I had several tests I was hoping it would pass and

it did. It floated, it didn't leak, it didn't flip over backwards or

sink from behind when I put the motor on it (my wife had some money on this

happening), and most importantly IT PLANED. I am not too happy with my motor,

it is a 1970 Johnson 10hp, and I have to keep pumping the gas to get it to go

at top speed (but for what I paid for it I'll be happy if it lasts one more

season). The steering was a little tricky to hook up and I think I've got

it backwards but I'll fix that next year. This boat is very buoyant. I can

stand on the side at the back and it stays upright. There is lots of room on

the front. We sit up there and fish. I was able to teach my 14-year-old cousin

how to start the motor (and more importantly how to stop it) and then he got to

take it out solo. He was so happy and had lots of fun so it made the project

worthwhile. My kids just go for rides as they are young but I hope the boat

survives a couple more years so they can get out in it.

|

|

I didn't have any handling problems. I used a fin on the bottom, which may have helped, but it adds 4 inches to the bottom that can make launching, storing and towing on a trailer a little harder. The steering may be a little loose but I need to work on it some more. I bought a used wheel and drum, then the parts I needed from Glen-L this helped to keep the cost down. Go to a furniture refinishing shop to get your foam for your seats, the place I went to, custom cut my foam to fit my plywood.

I started my project in April and finished the second week of August. It started a few hours here and there but I really wanted it done for August so at the end I was working pretty much every night on it. I'm glad I spent a lot of time on the bottom of the boat. I think the work there comes out in the ride. The area I could have spent more time on was in the finishing. I could have sanded a lot more of the fiberglass. The hardest part to sand was the sides and it shows as you get close to it. I also just painted it white so it is king of boring. Maybe a better paint job for next year.

|

|

I'd be happy to answer any questions anyone has about building it. I will be storing the boat in my garage if anyone is in the Toronto area and wants to get an idea about what it looks like finished.

Finally a large thank you to everyone on the Boatbuilder forum. I couldn't have finished it without your help. Michael

|

|

Just for your info. I live in Canada and found it very easy to get your products. Your shipping costs are quite low. If anyone asks about duty etc... Under NAFTA pretty much everything will come through without duty but you have to pay GST (our federal tax of 7%) and a brokerage cost to clear any large packages (handled by your courier service) I think on my initial order of the kit and some supplies the GST and brokerage came to about $70.

Your website and Boatbuilder forum were the best parts about this experience. I doubt I could have finished it without it.

Thank you for your patience,

Michael Dawson

Toronto, ON Canada