Inboard Hardware: Making the Shaft Hole

Page 3...

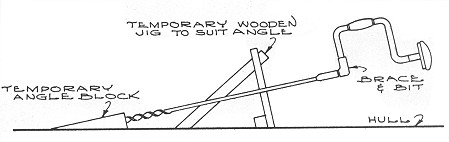

Some use a block of wood fastened firmly over the point where the hole will need to be drilled in the hull. It is possible to pre-drill a hole in the block and cut the angle (if required) to match the angularity required for the shaft hole (see Plate 39). The hole is used as a guide in the block to drill the shaft hole with a standard auger or expansive bit. Regardless of the method, the side opposite the one where the drilling is being done should have a block secured firmly in position so that the drill will make a clean splinter-free hole when breaking through.

Certain precautions should be made before boring the hole. By closely following the illustrations and captions, the task can probably be performed with a minimum of errors. Careful checking should be made throughout the operation to assure that the bore is going true. If a helper is available, careful sighting can be made in both directions. Any kind of a suitable guide or "jig" will help make the bore straight and true. Care should be taken to assure that no fastenings will interfere with the bit. If possible, any fastenings or bolts, which are obviously in the way should be withdrawn and/or relocated. If the hole is not perfectly straight and true but is large enough, it may have little consequence on the installation as long as the shaft clears. An old trick of shipwrights is to ream out an untrue shaft bore with a red-hot iron on wood hulls to "correct" an untrue shaft bore. However, always keep a fire extinguisher handy if using such a procedure.

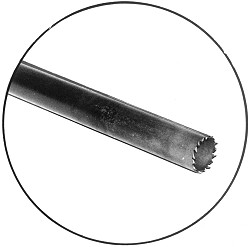

There is another easy way of drilling shaft holes, much used by the professional builder. This method uses a special made tool (see Fig. 12-5) that consists of a hole saw or hollow boring bit on one end of a shaft of the diameter required for the hole. The hole saw can be made by using a length of seamless tubing with teeth filed on one end. The length of the tube can be a foot or two depending on the length of the hole. The other end has a threaded portion welded at the tip to accommodate the boring shaft. The tube will need to be heat-treated after filing the teeth to harden them. As the teeth make the cut, the tube will fill with the excess material from the cut. Since the tube and the boring shaft are threaded together, the boring bar and tube can be withdrawn from the hole in making long cuts and the two pieces separated to clean out the tube before boring farther. With this tool, just about any length of hole can be made.