CHAPTER 20 - Righting the hull

From "Boatbuilding with Plywood"

To complete the construction of a plywood boat, the hull must be tipped right side up, or righted. The manner in which this is done largely depends on the size of the boat. With small boats, there is little problem since sufficient manpower can do the job. However, as the size of the boat increases so do the problems. In addition to the problem of righting the hull, the builder must consider and plan his construction so that all the various processes such as fiberglassing and finishing the hull are properly coordinated. Therefore, before righting the hull, do a lot of thinking to make sure that everything is ready. It would be a sad thing to go to a lot of trouble in righting the hull and then discover, for example, that the fiberglassing operation, if desired, had been overlooked. Ideally, painting and finishing the hull is completed before righting the hull.

A primary consideration in righting the hull is for the builder to realize that the hull structure at this point will be relatively weak. Before the decking structure and the deck have been added, the hull can easily twist or warp out of alignment, particularly in the case of lightly built boats. Therefore, it is imperative that the hull alignment be maintained before, during, and after the righting operation. Once the hull has been righted and leveled into position both lengthwise and athwartship, it should not be moved until the decking structure has been installed. If the hull must be moved before this time, it should again be rechecked for alignment before continuing with the construction.

Whenever possible or practical, it is best to right the hull AND the building form together. Doing this will keep the hull rigid and true, besides making it easier to maintain the reference points for completing the inside and easing the job of removing the building form members from the hull. Of course, on larger boats, the weight of the building form would add considerable weight to the hull righting operation, and this should be considered.

The means and devices used to right a hull seem to be limited only by the imagination of the various builders, and consequently there is no preferred or "best" method. Much depends on how much manpower or how much money the builder may have available. Therefore, the methods described in the following should not be considered as the only ways to right a hull. These are merely some methods that can be used, and may not be the most suitable for a particular boat. In picking a method, always take into consideration that lifting the boat up to turn it is usually the simpler part of the task. It is the lowering of the boat down once it has been flipped where the most care and effort must be exercised. On most boats there will be limited ways of holding on to or securing the hull as it comes down right side up.

Most amateurs are usually a little nervous when the righting operation is contemplated. This is probably because the hull may appear to be very large, especially when it might be occupying all of one's garage or yard. However, the typical plywood boat, even though it may seem big and bulky, is usually not as heavy as one would think. For example, the average 20' plywood boat hull on the building form will usually approximate only about 1000 lbs., or only somewhat more than a good-sized piano. Consequently, boats up to this size range or slightly larger are most often righted by manpower alone.

The manner of righting a hull using manpower alone will vary depending on the size and weight of the boat. But regardless of the size of the boat, once the hull has been righted it must be set onto something that will hold the boat for the balance of the construction. This can be any sort of jig or cradle that will provide level and rigid support. A cradle on rollers is preferable if possible. Or on the typical trailerable boat, the cradle may be the actual trailer that will be used to haul the boat. This is an excellent way to do the job since it is easy to level and move about such a trailer for completing the rest of the construction. Leaving the wheels off will bring the boat closer to the ground for easier access to the inside.

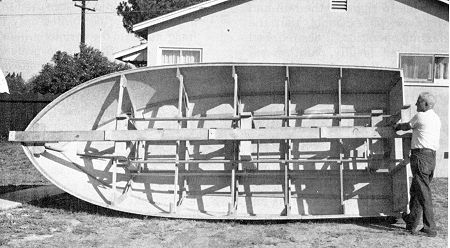

FIG. 20-1-This 17' plywood boat is being righted together with the building form. A total of three men easily performed the task. Notice that one man can support the hull on edge, while the others move around to the other side to let the hull down gently.

Obviously, if the boat is so small or light that a few people can pick up the ends and simply flip the boat over, not much else need be said except to take care not to chip any paint and to pad any of the forms on which the boat will set. However, on larger boats, more care and thought must be taken. The typical procedure when using manpower alone is to have plenty of room to one side of the boat. Use several old tires on the ground onto which the hull can be rolled since it will not be practical to actually lift the boat as such. Instead, the hull will actually be "rolled" right side up. As noted, the form can be left in the boat. However, if the hull is first removed from the form, be sure that there are some cross braces between the sheer clamps since the hull may be resting with all its weight on a limited area of the sheer momentarily during the rolling.

Gather together as many people as you can find to help in the righting or "rolling" operation. Sometimes a good old "party" with lots of beer will get everyone enthused and help relieve some of the anxiety. Everyone then lines up on the side opposite the clear area and lifts the boat up to where it is teetering on edge, resting on the sheer and supported by the tires so as not to damage the hull. Once at an equilibrium point, it only takes a few people to hold it in this position. Then everyone quickly runs around to the opposite side and lets the hull down slowly and carefully onto the tires, which should be carefully located to prevent the hull from hitting the ground. The hull can then be lifted or jacked up and the supporting cradle or trailer placed underneath.

A second but similar method can be used and usually applies to the larger craft. All the elements are similar, but instead of using manpower, a light crane is substituted. The crane controls both the lifting and rolling procedure all along, even though some manpower must be used to properly guide the hull. While the use of a crane may seem extravagant, the time required is only brief, and the safety and control; especially where a large, heavy hull is concerned is usually worth the money especially if many helpers are not available.

A precaution should be noted at this point, and this concerns the righting of large sailboat hulls that may have the ballast installed in or on the hull while it is upside-down. When righting a hull of this type, considerable care must be given during righting because of the leverage such ballast will exert. Once such a hull reaches a certain position, the leverage arm of the ballast could quickly snap the boat over and cause quite a hazardous situation. Therefore, some means of control, such as with lines to the ballast or keel bracing, should be provided that will restrain this action.

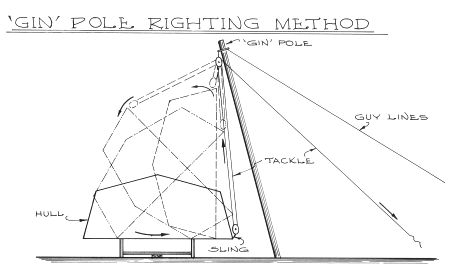

PLATE 20- The "gin pole" method of righting a hull as described in the text using blocks and tackle. A "cradle" can be built around the hull for protection and to provide an automatic "righting place".

Another method for righting a boat is to use a series of blocks and tackle from a gin pole (see Plate 20). The pole must be long enough for the tackle to reach beyond the beam of the boat when it is on edge. The gin pole is erected approximately at amidships on one side of the hull. The tackle is hooked to a sling around the hull that cannot slip. The pole must be supported with guy wires to the sides so it will not fall. As the hull is gradually lifted, it must be pulled to about the same area as when it was upside-down. Depending on the size and weight of the boat, several helpers could be required, both to control the tackle, and to guide the hull. The more parts forming the tackle, the easier the tackle will lift the hull, but the slower the tackle will travel through the blocks. On heavier boats, it would be possible to use two such arrangements side by side, however, this could take even more manpower.

A method that can be used, especially on a heavier hull where limited manpower is available, is to jack one edge of the boat up progressively- Use braces to hold the boat on edge while shifting the jack up on supports as the limit of each jack is reached. Once the bloat is on edge, use guy lines, preferably from each end of the boat and connect these to the trailer hitch of a car or to a good, stout bumper such as that on a pick-up truck. Locate the vehicle at right angles to the hull approximately amidships so the guy lines form approximate 45° angles with the boat's centerline. The guy lines support the hull on edge, and then the vehicle can be slowly backed to let the hull down on the right side. Care should be taken to ease the fall of the boat and to prevent it from "scooting out" along the bottom as it is lowered. Obviously, with this method there must be considerable room to one side for the vehicle to maneuver.

Finally, a novel method that has been used by some builders is to treat the hull of the boat much like a hunk of meat on a broiler rotisserie. Scaffolding is erected at each end of the hull, which is somewhat higher than the hull is wide. The hull is raised off the ground to a height equal to just slightly more than the half-beam. Then a good sized length of pipe is spanned between the scaffolding under the hull and is securely anchored to the hull at several points to form the "spit" about which the hull is then rotated. Lines attached to either side are used to tip the boat and to control the speed of the roll. On heavy hulls, a series of blocks and tackle can be used for greater leverage. After the hull is righted, it is then lowered down into a cradle slid underneath for the balance of the construction.

FIG. 20-2-After the hull has been completely planked and righted, it should be securely chocked in the fore-and-aft and athwartship directions. Extreme care should be taken to level the hull about the set-up level or other reference plane. At this stage of the construction, the plywood hull is relatively weak and will tend to distort if not lined up properly. With a hull that is leveled accurately, it will be possible to use a builder's square and a level to construct the interior and cabin.

With some sailboats that have ballast keels, the hull and ballast keel unit are built separately. When the hull is righted, it must be set onto the ballast keel unit. When this is the case, the hull can be righted by just about any of the means described. However, it must be raised high enough to set onto the keel member. In some cases this will be complicated by keel bolts that may have to align and pass through floor timbers on the inside of the hull. This will require that the hull be lifted even higher than the ballast keel itself. While it may be possible to jack such a hull to this height, in most cases a light crane is advised since aligning the hull exactly in position can be more carefully and easily done, and is also much safer.