A place to share YOUR boat building story

Glen-L Marine Designs - 9152 Rosecrans Ave. - Bellflower, CA 90706

In this issue

In this issue

-

Featured Design: Glen-L

25

-

Deceptive Destroyer by

Chris Caswell

-

Replacing Sacrificial Anodes

by Steve Noury

-

Designer's Notebook: Why Not

Bung Your Screw Heads?

-

Calendar

-

Power Boat Power by

ArtDeco

-

Photos sent in since the last

WebLetter...

-

Shop Talk: Using Wood

Plugs

-

Recent eMail

-

eMail of the

Month

GLEN-L Update

-

Early this month Gayle, Buckshot and I attended the

"West Coast Rendezvous" of Glen-L boatbuilders

at Bethel Island in the Sacramento Delta area of

California. It was a great treat to personally meet some

of our builders and their families, marvel at the

workmanship of their boats, and enjoy the cookin' of

some wonderful cooks & chefs (not to mention the

delicious "home brew" beer). We were also very

happy to once again see DwainCoulton (whom we met at the

"Gathering" last year) and note the tremendous

progress of his Ski King. Of course, not enough can be

said for the planning, organization and promotion done by

DeltaDawg, and the hand-made mini-buoy key chains he made

for everyone! DeltaDawg is really building this annual

event into something no one should miss!

2008 Rendezvous Video (Gayle's first ever YouTube video) - We've heard from some of our boatbuilders that they'll be attending the famous Wooden Boat Show at Mystic Seaport in Connecticut this coming June and showing off their Glen-L designed boat(s). When I get reports back from the show I'll pass them along in an upcoming WebLetter.

- Personally, I'm really looking forward to the next "Gathering" of Glen-L boatbuilders at Lake Guntersville, Alabama this coming October. Last year was a bit of a whirlwind trip for us due to my scheduling conflicts, but this year we're planning on a more leisurely trip so that we can more fully enjoy the company of some very "interesting" people (if you know what I mean). I sincerely hope that as many of you as possible can make the time to get to the gathering. Whether you're already enjoying your completed craft on the waters near your home, or your dream boat is still just a twinkle in your eye, I guarantee that you'll learn a lot (without even trying) while you have a wonderful time with a truly fun group of people. And Lake Guntersville/Guntersville State Park is exceptionally spectacular!

- Be sure to check the Calendar section below for more information about these events and several others.

- Thanks so much for the outpouring of emails and letters and photos this month. Although it makes it more difficult for me to keep up, it is extremely gratifying for all of us here at Glen-L when you include us in your fun, and it makes for a much better WebLetter, too!

Until next month . . .

Editor

Featured Design: Glen-L 25

A trailerable single- or double-cabin cruising sailboat

I n last month's webletter, we

reprinted an article from the Orange County (California)

Register newspaper about the annual sailing race from Newport

Beach, California to Ensenada, Mexico.

About 380 boats of all sizes and values gathered outside the

Newport Harbor at noon that Friday to depart on the 125-mile

journey to Ensenada, during the 61st annual event touted as

the "world's largest international yacht

race."

At the end of the article, we observed that the beautiful,

lightweight & sleek Glen-L Ensenada 25 is designed for

both comfort and performance and that in its first

Newport-Ensenada Yacht Race the original Ensenada 25 placed

2nd in PHRF Class-G ahead of over 50 other boats, and also

beat winning boats in Classes C, D, E, F, & H on

corrected time.

It should be noted that the Ensenada 25 is actually a

slightly-modified Glen-L 25, which WON the Newport-Ensenada

race in 1979 by a first-time builder…

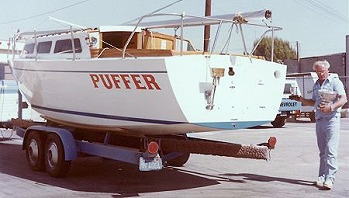

"A plywood hard-chine Glen-L 25 Solo model named

'Puffer,' built and sailed by Mr. Woody Sanders, took

First Place honors in the PHRF 'G' Class of  the 1979 Newport-Ensenada Yacht

Race." Woody and crew finished the 125 mile race in an

elapsed time of 28 hours and 39 minutes. Not only did

Woody's boat win in "G" Class and also beat the

first place "F" Class boat as well (with a

corrected time of just over 19 hours), but came very close to

the overall corrected time winner (a 40' boat) and that

of the famous plywood hard-chine boat the 62' Ragtime

(recently fitted with a new, faster, more efficient

keel).

the 1979 Newport-Ensenada Yacht

Race." Woody and crew finished the 125 mile race in an

elapsed time of 28 hours and 39 minutes. Not only did

Woody's boat win in "G" Class and also beat the

first place "F" Class boat as well (with a

corrected time of just over 19 hours), but came very close to

the overall corrected time winner (a 40' boat) and that

of the famous plywood hard-chine boat the 62' Ragtime

(recently fitted with a new, faster, more efficient

keel).

The race was mostly a downwind run under spinnaker with

heavy wind and

Deceptive Destroyer

A silent predator is eating away at your boat: Learn to prevent costly corrosion...

by Chris Caswell

We'd been struggling to remove the lower unit of my friend's outboard for an hour, with distressingly bad results. Three of the four bolts had pulled out of the cast aluminum drive, and we were now looking suspiciously at the fourth. With great trepidation (and a flood of WD-40), the socket wrench went back on and my friend gave it a tug. It moved slightly, and the entire bolt pulled out, dropping the drive on the garage floor.From inside the hollow casting came an explosion of fine grit. When we picked up the drive and turned it upside down, a sizable pile of the grit formed on the floor.

"What the heck's that stuff?" my friend asked me. "I think," I replied sadly, "that it's your lower unit after electrolysis ate everything else away." We had solved the mystery of why his prop shaft seemed loose, and we'd rediscovered why it's so important to make sure the zinc anode on the lower unit is checked regularly.

What Is Corrosion?

Corrosion is a major problem aboard every boat, and not just on metal under water, but every metallic item on or inside your boat. Dampness, salt spray and humidity make corrosion breed.The most common type on your boat is galvanic corrosion. This takes place when two dissimilar metals are submerged in an electrolyte (a liquid that conducts electricity) with the result being a battery that generates electrical current. Flowing from one metal to the other, it eats away at the weakest (least "noble") of the two metals.

A second type of corrosion is electrolytic, caused by currents from outside your boat, such as leakage from your shore-power system or a mild electrical current from a nearby boat.

There are more ordinary types of corrosion as well, such as rusting and pitting. Iron and steel (your engine block) get a common reddish-brown rust wherever bare metal is exposed to dampness. Aluminum doesn't "corrode" but rather forms a layer of oxidation on the surface that looks like dull grime and whitish lumps.

Preventing Corrosion

The primary method to defeat both galvanic and electrolytic corrosion isReplacing Sacrificial Anodes

by Steve Noury

I f you're like many people who

keep their boats in the water, you may be neglecting to

periodically replace your sacrificial anodes. Galvanic

corrosion can damage or even destroy the underwater metallic

boat parts. When two different metals are touching each

other, or are electrically connected by an electrically

conductive fluid like fresh or salt water, the "least

noble" of these metals (called the anode) will corrode

faster than it normally would. In this example, Martyr Fresh

Water Magnesium Anodes supplied by West

Marine are installed.

Step 1

A knowledgeable understanding of the problem is the first place to start. Galvanic corrosion can often happen in a single piece of hardware - particularly alloys, which contain more than one metal. Interactions

between the differing metals in the alloy will dissolve the

least noble of the two. That's why it's so important to

use marine-grade fasteners (bronze, monel and 316 stainless

steel) in underwater applications so they're not destroyed,

which can cause a hose clamp to fail or your propeller to fall

off. Keep in mind that the higher the salinity and temperature

of the water, the greater the likelihood of corrosion. Breaking

the electrical circuit between exposed metals by connecting them

to a sacrificial anode will prevent galvanic corrosion and

damage to your boat's metal parts. Replacing the anodes is

an inexpensive and easy project.

contain more than one metal. Interactions

between the differing metals in the alloy will dissolve the

least noble of the two. That's why it's so important to

use marine-grade fasteners (bronze, monel and 316 stainless

steel) in underwater applications so they're not destroyed,

which can cause a hose clamp to fail or your propeller to fall

off. Keep in mind that the higher the salinity and temperature

of the water, the greater the likelihood of corrosion. Breaking

the electrical circuit between exposed metals by connecting them

to a sacrificial anode will prevent galvanic corrosion and

damage to your boat's metal parts. Replacing the anodes is

an inexpensive and easy project.

Designer's Notebook: Why Not Bung Your Screw Heads?

Bung, in marine parlance,

means to cover a countersunk counter-bored screw

with a wood plug. In common use, the term

"plug" is synonymous with bung. This is

ordinarily done on the hull, decking or almost any

wood surface that will be finished naturally. The

practice was commonplace on the older classic

runabouts but has currently carried through to

decking and interior surfaces of mahogany or similar

attractive woods.

For more on using wood plugs see "Shop Talk" below . . .

|

Calendar

24th

Annual Antique and Wooden Boat Show and Woody Car

Show

June 7 - 8 @ Lake Arrowhead Village, Lake Arrowhead,

California

21st Annual Antique & Classic Boat

Festival

June 13 - 15 @ St. Michaels, Maryland

17th Annual Wooden Boat Show

June 27 - 29 @ Mystic Seaport, Connecticut

32nd Annual Lake Union Wooden Boat

Festival

July 4 - 6 @ Seattle, Washington

Corinthian Yacht Club Wooden Boat

Show

July 12 - 13, @ Tiburon, California

Lake Tahoe Concours d'Elegance

& Wooden Boat Week

August 7 - 13, @ Lake Tahoe, California

Port Townsend Wooden Boat Festival

September 5 - 7, @ Port Townsend, Washington

The Gathering of Glen-L

Boatbuilders

October 25 & 26 @ Lake Guntersville, Alabama

Power Boat Power

When picking an

engine -ArtDeco |

Photos sent in since the last WebLetter... |

"The important thing is not being afraid to take a chance. Remember, the greatest failure is to not try." |

Shop Talk: Using Wood Plugs

Woodscrews are a sure-fire way to assemble a project securely. The problem is there are times when you don't want the screw heads to show. Simple problem right? Just counterbore the screw hole and then use a wood plug like the ones shown above to cover up the head of the screw.

The type of plug you use and how you install it can make a big difference in how it looks. For instance, most store-bought plugs are cut from the end of a dowel. So they absorb stain or finish like a sponge. This makes the plugs darker than the surrounding wood so they end up standing out like a sore thumb.

An easy way to get around this is to cut your own plugs. This way, you can cut a face grain plug that will absorb finish more easily. Another advantage is that you can use the scrap pieces remaining from a project to create an almost invisible plug, as shown in the upper photo at right. Or maybe you'd like to highlight the plug by using a type of wood that contrasts in color, as shown in the lower photo.

Regardless of the look, you still want the plug to fit the hole like a cork in a bottle. To do this, follow the simple six-step process detailed below.

1.

With a plug cutter chucked in a drill press, cut the plugs in a scrap piece from the project. Be sure to make a few extra. This way, you'll be able to select a plug that best matches the color and grain of your project.2.

The next step is to free the plugs from the workpiece. To do this, clamp a tall auxiliary fence to the bandsaw table and cut the plugs so they drop free.

3.

With a pile of plugs in front of you, it's tempting to start gluing them in place. But take a minute to select just the right plug for each hole that matches the grain and color of the surrounding wood.4.

To avoid a big mess, don't apply glue to the plug. Instead, brush glue around the sides of the hole. Then tap the plugs in place. Just don't overdo it. The plug doesn't have to "bottom out." All you're looking for is a snug fit.

5.

Now it's just a matter of removing the part of the plug sticking above the workpiece. To avoid scratching the workpiece, slip a scrap of posterboard (or plastic laminate) with a hole in it over the plug as you saw off the waste.6.

With the excess waste removed, all that's left to do is sand each of the plugs flush with the surface of the workpiece. A block and some sandpaper make quick work of this.

Recent eMail:

Subject: Gayle's Build your Dream Boat Newsletter

Date: 30 April 2008

I even made several attempts to build a boat from the pictures in the catalog, one even floated and worked fairly well on our stock pond even though I made it clinker fashion out of pine boards. I moved on to plastic ski boats and the need for speed until I discovered sailing on a friend’s Hobie cat.

Even though I loved the water, I made a career of the Air Force and managed to own a boat of some sort in every country I was

stationed in, mainly

sail boats. With larger sailboats came the need for a dinghy and

thus the return to Glen-L and boat building. I even dreamed of

building one of your large sailboats, but just could not find

the time it would take. I built several of your dinks in pursuit

of the perfect tender, the largest being the Row Me. I enjoyed building everyone of them

and they were good boats. We even owned a custom built 38’

wood ketch for several years and the experience I gained from

building dinks from your plans was invaluable for maintaining

it.

stationed in, mainly

sail boats. With larger sailboats came the need for a dinghy and

thus the return to Glen-L and boat building. I even dreamed of

building one of your large sailboats, but just could not find

the time it would take. I built several of your dinks in pursuit

of the perfect tender, the largest being the Row Me. I enjoyed building everyone of them

and they were good boats. We even owned a custom built 38’

wood ketch for several years and the experience I gained from

building dinks from your plans was invaluable for maintaining

it.I retired from the USAF about ten years ago and now live and work on Okinawa. My family and I sail a heavily modified Morgan Out Island 41, which we rebuilt and modified to our desires. We are now prepping it for extended cruising as soon as our son graduates high school this June……… I still have one of those blue catalogs………

-- John, Naomi & Wes Howard

SV Horizon, Okinawa, Japan

Subject: Memories

Date: 30 April 2008

Now I live at Monterrey bay, and I am looking for a new boat. Lots of choices out there. Great new boats, but pricey. Used boats are always an option. I think my next boat will probably come from Glen-L. That seems to be where the best custom boats at a reasonable price can be found.

-- Lew Green

Monterey, CA

Subject: Gayle's Newsletter

Date: 30 April 2008

Thanks for your emails. I am in the middle of two kayaks and two more canoes are right on their tail.

When I retire from teaching I would love to teach boat building. It brings great pleasure.

Keep doing the great job you have been doing.

God Bless,

-- Steve Zill

Subject: Gayle's Newsletter

Date: 1 May 2008

-- Corey Duberstein

Richland, WA

Subject: Gayle's Newsletter

Date: 30 April 2008

When I was 8 I was lucky enough to have an old wooden row boat float up on shore in front of my house...I immediately pulled it up on shore and bailed out the 1000 or so gallons of water that completely filled her...it took me hours but I had dreams of cruising the lake in my new find.

Back in those days (1959) it was common for old row boats to be set adrift when people didn't want to repair them or pay to have them hauled away. Anyway I pulled it out of the water with the help of my two cousins who were 18 and 20 respectively.

My uncle Lou who was the handiest person alive helped me repair the boat by replacing bottom boards that had rotted out. I painted the thing and made it look great...at least through an 8 year olds eyes. We got an old Scott at water 3hp engine and I started my boating career.

When I turned 15 my uncle helped me build your dad's Tiny Mite 8' hydro then when I was in my 20's I built the TNT which my son resurrected a while back...presently building the Crackerbox. So I started like you...and still love it. Thanks for igniting my memory bank.

Warm Regards,

-- Michael Wasserman

Subject: Webletter 100

Date: 7 May 2008

I will certainly look forward to the read and also to the next Webletter. Thanks again!!!!

-- Rob Miller

Subject: Webletter 100

Date: 1 May 2008

-- Wayne Cooper

Subject: Webletter 100

Date: 1 May 2008

-- J.R. Sloan

Subject: Center of Buoyancy

Date: 7 May 2008

In inboard hydro-racing, we often had the luxury of being able to move the engine fore-aft a few inches to balance the boat and on a windy day moving the CG forward could allow greater speeds if racing into a head wind.

I guess moving the battery is the easiest way to adjust the balance since they are small volume but "right heavy".

I love this WebLetter!

-- Jay Degges

Subject: Glen-L Order

Date: 19 May 2008

I've only had a brief opportunity to glance through the catalogue, but it immediately sent me back to my teens, and the first boats that I built. You and Popular Mechanics were all the incentive that I needed to get started.

And no, I'm not going to tell you how long ago it was. Just that you can count it in decades more easily than in years!

I look forward to a more in depth study of the catalogue, your newsletters and future building with my nephew and nieces. Yes, the girls love building things with me.

Thank you again.

-- C. Goad

Aurora, Ontario, Canada

eMail of the Month

Subject: Project Registry: Fancy Free

Hi, my name is Chuck Perkins and I hail out of Reno,

NV. Recent earthquake swarms, a depressed real

estate market and a grown daughter that has recently

fallen back into the nest have all conspired to dash

my midlife crisis dream of retirement and

floating/motoring off into the sunset. Glen-L to the

rescue. My garage is now my refuge and a set of

Fancy Free plans my sustinence. I am well into the

planning and learning phase. So well, in fact, that

I am about ready to flip a coin when it comes to

crucial decisions, some of which, if my research is

correct, suggests that blood has been spilled in

defense of opposing positions.... Doug Fir ply or

Okueme? Doug Fir frames or White Oak? Encapsulation

or just fg the exterior hull and deck? Cpes? 4 oz, 6

oz, 10 oz. or other? Scarf or block? Hull

insulation? And where do you find those cool Bronze

ports while only paying half of a king's ransom.

Arrrrgh! (Arrrrgh is a word that came from pirates

who obviously built their own boats). |

GLEN-L boats, of course