WebLetter 13

An Occasional Publication for the Home Boat Builder

Glen-L Marine Designs - 9152 Rosecrans Ave. - Bellflower, CA 90706

In this issue

- Building the Tunnel King - Part 2 by Matthew Green

- Boats in "exotic" locations: Drifter

- Squirts in Minnesota

- Who is that guy?

- For the Rag Man: Care of sails

- Boat building in Skopelos Tom Dempsey

- Recent email

Glen-L Update

Website:

- Not much change since the last WebLetter. We have added quite a few pictures to Customer Photos. Whenever there is a letter with a photo, we include it. There is frequently good information about performance or costs, so be sure to check for information about the design you are interested in. We have also had many additions and updates to the Project Registry. Is your project "registered"?

- In answer to an email request, we have added a page to the Supplies pages, "POXY-SHIELD Resin Estimates for GLEN-L Encapsulation System". This page lists the amount of epoxy resin required to encapsulate the inside of various Glen-L hulls.

-

This WebLetter features articles and letters from several of our

builders. We thank them very much for their contributions and hope more

of you will be encouraged to submit something to help your fellow boat

builders.

- Part 2 of "Building the Tunnel King" by Matthew Green

- Our first photo of a Glen-L boat in "Exotic Locations"... kinda wonder where the guy with the camera was standing. To see a complete version of this photo, click on the photo below.

- Squirts in Minnesota: Gary Baker shares photos of Glen-L Squirts he took at the "Bob Speltz-Land O' Lakes ACBS Rendezvous in Red Wing Minnesota".

- Tom Dempsy's trials and tribulations "Boat building in Skopelos", Greece.

- Also in answer to the reoccurring, "who is that guy, is he Glen L?", we are spilling the beans.

- I have had three questions this last month about the Tiny Might: "what motor can I use" times 3. If any of you out there have built the Tiny Might or have experience with a lightweight (300 lbs max.) marine inboard performance motor, there are people out there who would like to hear about it.

- Work on the PowerYak test model is progressing very slowly. Although we have over 120 frame kits in stock, we've been getting orders for out of stock kits. Allyn has been working hard to keep up and has little time for other projects.

- Glen has been hard at work on an electric boat video. We hope to have something before December.

Barry Witt

Editor

Building the TUNNEL KING, Part 2

Materials, Tools, Frames and Building Jig

by Matt Green

Continued from WebLetter 8

First, I must apologize for the delay between article one and two; I work, go to school, and constantly mess around with boats and motors, leaving me little spare time for writing. The articles will now be bi-monthly (I hope), but if anybody is actually building a Tunnel King at the moment and needs help, I can be reached via e-mail.

Now that I have covered the basic kinds of high performance boats and their characteristics, let's delve more deeply into the construction of the Tunnel King. It should be noted that this article, and those following it, is not meant to replace the building manual that is included with the Tunnel King blueprints. I will try to clarify and give hints based on my building experience, but in general the building instructions should be closely followed. Likewise, basic boatbuilding joinery will not be covered as the potential builder is assumed to have some woodworking skills.

WATER CRAFT Magazine

I received a new magazine today... well, not new, but new to me. The cover looks alot like WoodenBoat, and like WoodenBoat, it is full of full color photos. Although not as thick as WB, it seems more accessable. With articles that seem a little more practical. I suppose they sent us the magazine in hopes that we would advertise... we might. Did I mention that the magazine is published in the UK. The price per issue is £3.30, I have no idea how much that is. A US subscription is £21.00 (£17.50 in the UK). If you would like more information about the magazine, see their web site: www.watercraft.co.uk. There isn't alot of information there but it loads quickly so you won't waste much time finding out if you're interested.

Boats in "exotic" locations: Drifter

Subject: Drifter 16

Date: Mon, 30 Aug 1999

In response to your request for boats built from your plans, pictured in exotic places, I have included an attachment which is a picture of my 16' Drifter which was originally built in 1989. She is shown here in Lava Falls, the largest rapid in the Grand Canyon. The Rincon Maiden was built as a whitewater dory with additional decking on the inside to accommodate water proof storage and floatation should she ever be swamped. I built her in one month, although she was not painted when launched on her maiden voyage in the San Juan River in Utah. As I ran her on various rivers, I could see changes that needed to be made. She evolved over the years until 1997, which saw the biggest changes.

I extended the bow forward and up to bring her to almost 17'. The raise was needed due to the large waves that would be encountered in the Grand Canyon. Also the sheer clamps were beefed up to take the hard hits she would probably receive. I foamed in under false floors and drilled holes in the hull just above the false floors to allow the water to drain that would flood in the larger rapids.

Rincon Maiden performed flawlessly and when flipped in Spector and Lava Falls, she was righted easily by 2 men, despite the heavy load she was carrying. Everywhere we went she was the center of attention. Even in Amarillo Texas, where while sitting in a Walmart parking lot, we had people pulling of the interstate to check her out. She is a beautiful boat and I am very proud of the first boat that I ever built.

Please feel free to write me if you have any questions.

Your boating buddy, Bo Cole

Additional photo in Customer Photos

Squirts in Minnesota

Subject: Squirts in Minnesota

Date: Mon, 06 Sep 1999 22:19:07 -0500

From: Baker

Thought you might like to know that 2 Squirts-- one over 10 years old-- one 1 year old were on display with over 85 other boats at the Bob Speltz-Land O' Lakes ACBS Rendezvous in Red Wing Minnesota.

Over 7500 people paid $5 to view the boats.

Note the display board in the bottom left of the red & white one-- your Glen-L Plans on display with the happy boat owner. What a better use for your old outboard motor.

Seriously-- consider the market of the ACBS crowd that wants to build in plywood-- a good addition to your newsletter would be the relative "ages" of some of your vintage plans. What goes around, comes around.

Gary Baker

Who is that guy?

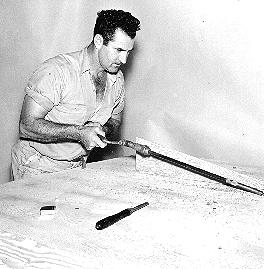

Among the most frequently asked questions are "Who is that curley haired guy in the 'Boatbuilding with Plywood' book?", and "Who's the guy in the 'Build it the Glen-L Way' manual?"

Well, it's not Glen L., it's Don Ruffa. Don Ruffa built boats designed by Glen L. Witt, and Glen went dealer to dealer selling them in the early 50's. When Glen-L Marine Designs became a company in 1953, Don Ruffa made the frame kits. By necessity he became the model in most of the construction pictures that became part of our book, Boatbuilding with Plywood and the pictorial manual, "Build it the Glen-L Way". He is also featured in many sets of instructions.

Glen always says he has never known anyone who could build a boat faster than Don Ruffa.

Don retired in 1971 to spend more time in his house at "the river". In Southern California, that's the Colorado.

| This is an archive photo of Glen and Uncle Donny, circa 1955. |

|

For the Rag Man: Care of Sails

about sailboats & sailing

Modern sails made from Dacron, such as those sold for GLEN-L sailboats, require minimal maintenance. Probably the most important single factor in sail care is keeping the sails clean at all times. During use and when the sail is being rigged or carted from shore to sea, the sail picks up dirt and grease from our smog filled air. Sailing in salt water can cause salt build-up on the sail, making it less effective as well as less attractive. Aluminum spars and fittings may transfer an oily residue to the sail as it rubs against them. This residue is extremely difficult to remove and it is best to prevent this from occurring by wiping down the spars as well as the stays which may also collect dirt.

Frequently the sails should be rinsed well with fresh water. The bath tub is an ideal place to do this. Use cool water and a mild detergent if they are very dirty. Do not wash Dacron sails in a washing machine nor dry them in a clothes dryer. Never expose the sails to any source of extreme heat or conditions that will chafe or abrade the fabric and stitching. You can wash and dry the sails on the lawn or on a concrete slab as long as you avoid drying in direct sunlight. Remember that when the sail is in use it is being cooled by the winds on both sides. If you dry them on the lawn, they should be raised up and turned over occasionally to keep condensation from forming on the underside. It is preferable to hang them so they can dry more evenly and quickly. Mildew will form on sails if they are stored while damp and without proper air circulation. This is harmless but makes ugly spots on the sail. Be sure you remove the battens before washing and make sure that the sail is completely dry around the batten pockets and bolt ropes before storing. Do not stow a clean set of sails in a dirty sail bag. It is good practice to clean the bag along with the sails.

Most sails come folded from the sailmaker and it is not a good idea to put in any other creases. So avoid cramming the sail into the bag tightly or storing gear on top of it while in the trunk of the car. If you don't want to take the time or trouble of folding the sail back correctly, roll it loosely in the bag and don't close the opening too tight.

The number one enemy of Dacron sails is friction and chafing, mainly against other parts of the boat. Wrap the stays, spreaders, and other parts which contact the sails with tape or other "chafing gear" to prevent wear on the fabric and stitching. Keep a close check for wear in the area of the headboard and clew outhaul regions. If you pull your boat onto the beach for any period of time, take the sails down. Letting them flap wildly about (called "slatting") will cause chafing and even cause them to rip out at the batten pockets and break the battens. Keep sand out of the bolt rope groove on the mast and boom, and wax the groove lightly to allow the sail to raise and lower more easily.

Inspect your sail prior to each use for rips and small holes as well as torn stitching. If there is any damage it is best to take care of it as soon as possible to avoid more extensive damage and higher repair costs. It is usually preferable to let a professional sailmaker take care of sail damage. They have the proper tools and can make repairs without changing the cut of the sail. Inspect your sails well before the start of the season. Then if anything needs repair, you will have plenty of time to get them fixed, the sailmaker will not be so busy, it may not cost as much, and your sailing season will not be interrupted by "canvas failure".

Boat building in Skopelos

by Tom Dempsey

This story is about building a boat away from traditional or familiar sources for supplies or information.

I live in Skopelos, one of a group of Greek islands called the Northern Sporades situated in the Northern Aegean Sea. For centuries Skopelos had a shipbuilding industry, due in part to the abundant forests which cover the island. The days of building large wooden vessels by hand have ended, though there is still occasional building of smaller boats up to 20 feet (6m) in length. These boat are traditionally built, ribbed and planked, steered by tiller and are powered by a small gas or diesel engine. They see use as fishing boats.

We've been living here permanently for three years and a boat has always been on our list of things to have. However, a boat has never made it to the top of our list as other necessities have prevailed. Yet each August during tourist season we swear that it would be our last August without a boat.

Recent email:

Jonathan Smith wrote:

Hi, I built an XP8 a few years ago, (actually it's currently hanging upside down a few feet off the ground, underneath my deck wrapped up in tarps)....Anyway the fibreglass we put on began to unlaminate from the boat...not the first coat, but it seems to be subsequent layers that were added which didn't soak into the cloth..I think we used polyester resin..any suggestions, so this doesn't happen again??

ANSWER: After the cloth is put on, additional fill coats stick to the resin, not cloth. If you have a bad bond, the surface was contaminated. One common contamination is wax. If you used a finish resin to apply the cloth, the wax must be removed prior to applying additional coats. Our polyester fiberglass kits use a multi-purpose polyester resin. It is a laminating resin to which an additional component (wax) is added to the last coat. Polyester resin will only completely cure in the absense of oxygen, hence the wax film on the surface. If you purchased the resin locally, it may well have been a finishing resin, with the wax already in the can.

name: Jeff Fuchs

State: LA

Zip: 70560

Comments: I don't know if your web site has won any awards, but it should! I spent nearly a whole day looking at every boat again and again. I am a do-it-yourselfer whose talents have only gone into restoring an old house, but now I want to build a boat.

I found your site because I was curious about building a travel trailer, but the boats stole the show.

You seem to have an excellent product and an excellent company. Thanks for the great web site.

name: Joseph J. Sottile

Country: USA

Comments:

Some twenty plus years ago, make that thirty plus years ago, a dear

cousin of mine was building a 42' Tri and he always said that your

company had the best line of kit boats. His name was Al Passantino, who

may have been known as PASS. After he died, I really missed his talent as

a boat builder. He bought a set of Huck Finn plans, gave them to me for a

project and I proceeded to lose them in one of my many moves. your

company is a class act and I look forward to getting involved once again.

keywords: Boat kit company with a great reputation

Subject: bill of materials, cabin skiff

Date: Fri, 27 Aug 1999 21:30:07 EDT

From:RHeagle

First of all, this is the most incredible web site in the whole world. I

have been dreaming of building a boat since I was in high school. I

ordered my first Glen L catalog in about 1976. I have been telling my

wife of 2 years I have always wanted to build a boat and she has always

just rolled her eyes..... Until she saw your website and the cabin skiff

site that you have a link to. You guys are really onto something here.

Now she can see me doing it in the future. Could you email or mail me a

bill of materials for the Cabin Skiff.

Thanx, Russ Heagle

Subject: Thanks Glen L !

Date: Sun, 15 Aug 99 17:09:50 -0400

To: Gayle Brantuk

Dear Glen-L,

I think I ordered my first set of plans from you in 1980 and have over

the years built many of your boats including a few "big" ones

such as the Carioca, Lucky Pierre and the Vera Cruise. Reading through

your web pages now brings back so many fond memories! Your plans were

always so clear and the satisfaction of being able to build my own boats

is something that will live with me forever!

I sent you a photo of my Lucky Pierre pulled up to a beach in the Bahamas which in fact you used in your Wooden Boat ad for a number of years. Do you still have a copy of that! She was a great sea going boat! A movie company filming a pirate attack in the islands bought her from me and then dropped a cannonball through it for that scene.. so she was actually famous for about 8 seconds!

My son is now five weeks old and I assure you as soon as he is able to walk we will be building another Glen L boat together.

Thanks again, Michael Toogood, Nassau.

Build more boats

Glen-L boats, of course