A place to share YOUR boat building story

Glen-L Marine Designs - 9152 Rosecrans Ave. - Bellflower, CA 90706

|

Performed by Jerry Jeff Walker |

In this issue

In this issue

-

Gathering 2008 - Last Call!

-

Glen-L Boatbuilder of the

Month

-

The Shipleys Visit

Glen-L

-

Designer's Notebook:

Battens

-

Propellers by ArtDeco

-

Photos sent in since the last

WebLetter...

-

Basic Boating Knots

-

Shop Talk: A Few Clever

Tips

-

Recent email

-

Cartoon of the

Month

GLEN-L Update

- October, and the leaves are about to turn color. Well, maybe not so much here in Southern California, but across much of the United States and the Northern hemisphere the fabulous fall folliage will soon be in full flourescence (say that 3 times fast - "fabulous fall folliage in full flourescence"!). We at Glen-L are looking forward to the 2008 Gathering and we know that many of you are eagerly anticipating it as well. Be sure to read the Gathering 2008 article (below) to learn the latest so you don't miss out.

-

-

This month's WebLetter is a little light on photos and

emails from our builders; we've looked into this

serious matter and found that a great many of you have

been very busy, out over the summer working on, completing

and enjoying your fine craft out on the water! This is a

good thing; a VERY good thing! We are glad to know that

Glen's efforts at designing beautiful boats is paying

off handsomely in building memories for you and your

families.

- Now that those of you in the Northern hemisphere have enjoyed the summer weather and your boats and boatbuilding, we sincerely hope that you'll honor us by sending us photos and stories about your experiences. The very best part of this WebLetter is always hearing (and seeing) about you, your families, and how boatbuilding and boating has enriched your lives. Sharing your stories and photos will not only educate and entertain our readers, but you'll find that you also will enjoy "reliving" the joys and pride of your own boatbuilding efforts.

-

- Thanks in advance for your photo and story contributions. I'll keep my eyes peeled for them and eagerly include your thoughts and memories in the next issue of the WebLetter.

Until next month . . .

Editor

Gathering 2008 - Last Call!

by John Brantuk

The time is here - only a few more

days until Gayle and I are off to join a multitude of Glen-L

boatbuilders at the 2008 Gathering at spectacular Lake

Gunthersville, near Huntsville, Alabama, October 24 -

26.

I'm not sure of the count yet, but it appears that there

may be as many as 50 or more of the Glen-L "extended

family" and possibly a couple of dozen boats at the

Gathering this year! This is truly becoming a grand annual

event.

We hear that the long range weather outlook says that the

highs will be in the 70's, lows in the 40's.

They've had good rain this year so the fall colors should

be breathtaking.

It's still not too late for those of you who'd like

to come join us - having experienced last year's

Gathering Gayle and I can do nothing less than guarantee that

it is a mini-vacation/experience you'll never

forget!

Everyone is welcome; whether your dream boat is fully

completed or your boat is still just a dream, you will enjoy

(and learn) the entire 3-day weekend.

All of us on the Glen-L team sincerely hope that none of you

miss out on this wonderful treat of great people, gorgeous

natural wonders, mouth-watering food and, of course,

magnificent examples of boat-building by people just like you

and me.

I think someone on the Boatbuilder Forum said it best when

they said

"It's like a family reunion. Only, YOU get to

choose your family!"

To learn more about this year's

Gathering or to be more involved and even help with planning

the event (if you wish), visit the Forum — "The Gathering

2008."

Glen-L Boatbuilder of the Month

Alex Neymark - Crackerbox

Talk about a

"perfectionist!" Alex Neymark, of Charlotte, North

Carolina, invested 5 years (part-time) and 5000 hours to

build his beautiful Crackerbox christened

"Dejavu."

Alex constructed her with great love and spectacular

attention to detail. The surface finish he gave

"Dejavu" consists of 12 layers of marine varnish

with a manual hand-sanding between each layer, and the last

layer was sanded with 2500 grit sandpaper and then

hand-buffed to perfection. Alex had extensive custom

stainless steel accoutrements and details fabricated for his

beautiful, beautiful craft.

We bet that Alex's "baby" inspires you as much

as it inspires us - imagining yourself boating on a lake,

river, or the ocean in a similarly well-crafted motor- or

sail-boat as all the impressed onlookers envy your "good

fortune" to own and enjoy such a fabulous boat.

The best part, of course, will be watching the expressions

on their faces when you tell them that "I built her

myself."

Editor's Note: See the complete construction photo timeline of Alex Neymark's Crackerbox in Customer Photos.

Alex and the Dejavu were recently highlighted in

the Charlotte Observer newspaper article

"How to build a dream -

Find a fantasy, add sweat, put in five years, then float away".

Way to go, Alex!

The Shipleys Visit Glen-L

AN "EXCELLENT EXAMPLE ..."

This past August 12 we at Glen-L were treated to a visit by

Mark and Don Shipley. Don (father) and Mark (son) recently

completed an absolutely beautiful Zip that they brought with them to the

Glen-L Global Headquarters/Command and Control Complex in

Bellflower, California to personally meet Glen and

(hopefully) get his nod of approval on their efforts. And nod

he did!

The Shipley's have crafted an excellent example of the

Zip, and impressed us all immensely. I took a number of

photos of Mark and Don with their Zip along with Glen, Gayle,

Darla and Buckshot in front of HQ. Glen was so impressed with

the quality of the Shipleys' craftsmanship and their

"excellent example of bottom batten reinforcement"

that he had me take close-ups which you will find here,

along with all the photos we shot during Don and Mark's

visit.

Mark and Don have provided a great "blow by blow"

description of their boatbuilding project from start to

finish. Review their Project Registry and Customer Photos to learn more.

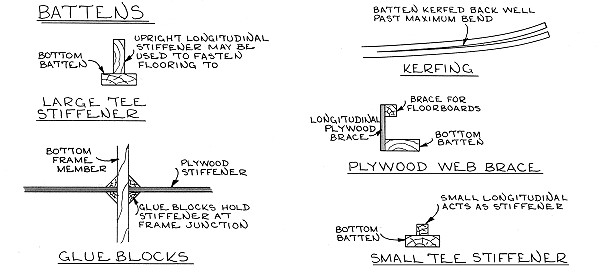

Designer's Notebook: Battens

Battens are longitudinal

stiffeners along the bottom or sides of a boat. The

battens rest on top of the frames (in the

"floating frame" type of construction) or

notch into the frames. Battens should be from stock

that is as robust as can be to conform to the hull

contours. The battens begin at the transom and

extend as far forward as possible. However, a batten

should never end on a frame, as this will set up a

localized stress that will often begin to break or

crack the planking skin at this point. Instead, the

battens should always end short of, or well past a

frame. |

PropellersFor power boatsPropellers are The motive means To go fast and far Props can be made Of aluminum or stainless, Bronze, even plastic Or materials nameless Diameter matters It can be small or big Be sure to check if It fits under your rig Some props turn left Others turn right Some have a small pitch Others take a big bite Blades are numbered Usually 2, 3 or 4 Though I have seen Five blades and more Cupping a prop Is a means you can try A curve in the lip May make a boat fly And then there is rake That alters the trim For less wetted surface With more zip and vim Factors for props, I've mentioned a few There may be others, Some old or some new So when picking a prop Give it careful thought To make your boat go At the full speed it ought -ArtDeco |

Photos sent in since the last WebLetter... |

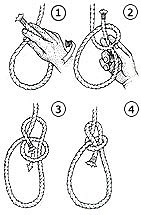

Basic Boating Knots

BOWLINE

The bowline (pronounced "bo-lin") is rightfully known as the king of knots. It is easy to tie and untie, increases its grip as tension is applied, and will never jam. It takes time and practice to learn, but the effort will be well rewarded. Use the bowline for attaching jibsheets and halyards to sails.

- With your palm down, hold the working end between your fore- and index- fingers, placing it over the standing part with your thumb.

- Twist your wrist so your palm faces up and a loop has been formed in the line.

- Pass the working end behind the standing part and then back through the loop. Remember, after the end passes under one part it must then pass over the next, Always alternating.

- Before putting into service, snug the parts up to make sure they are set.

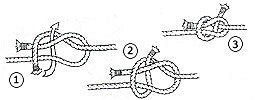

A bend joins two ropes. The worst way of doing this is with a square knot, which can slip or come apart. The best way is with the sheet bend. It is easy to tie, strong, secure, and works well with ropes of dissimilar sizes. If you are going to remember one bend, this is it.

- Make a loop in the end of one rope. If one line is heavier than the other, make the loop in it. Pass the end of the other rope through and around the loop as shown.

- The working end should exit the knot on the same side as the loop's short-ended side.

-

You may have noticed that the sheet bend is similar in

construction to the bowline, so it can

be tied in the same manner.

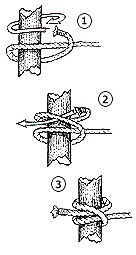

CLEAT

HITCH

In order to secure the boat to a dock or secure a line to the boat you will probably use the cleat hitch.

- Take the line to the ear of the cleat furthest from where the line comes from (the load).

- Take one wrap around the base of the cleat and then start a figure eight across the top of the opposite ear.

- Finish with a half hitch turned under so that the line is coming away from the cleat in the opposite direction from which it came in.

-

CLOVE

HITCH

The clove hitch is for tying to pilings when there aren't

any dock cleats. Its best feature is that it can be easily  tied

when there is strain on the line, as there might be when

docking in strong winds. The first turn around the piling is

usually enough to hold the boat, keeping everything in place

while you finish tying the knot. This is essentially a

temporary knot, and may slip if the direction and strain on

it changes.

tied

when there is strain on the line, as there might be when

docking in strong winds. The first turn around the piling is

usually enough to hold the boat, keeping everything in place

while you finish tying the knot. This is essentially a

temporary knot, and may slip if the direction and strain on

it changes.

- Take a turn around a piling.

- Take a second turn, this time crossing up and over the standing part of the line and the first turn. Tuck the end under and through the crossing you just made.

- Pull both ends to snug up the knot. For a more permanent knot add two and a half hitches around the standing part of the line.

These nautical knots, used when berthing a large vessel, docking your yacht, tying up dinghy painters, and managing sails are all aimed at safety and reliability.

The emphasis for boating knots is on reliability, matched with the ability to untie each knot fairly easily.

Click on the knot illustrations above to see an animation of the knots being properly tied, and to find more information about their applications and limitations.

just cut a new one" -- Glen-L Boatbuilder Stefan Karakashian |

Shop Talk: A Few Clever Tips

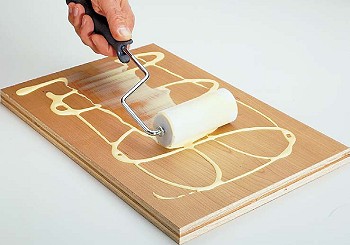

Glue

Roller

A lot of woodworkers like to use a

paint roller to spread glue over large surfaces. But instead

of using an ordinary roller cover, cut a piece of PVC pipe to

fit over the roller cage.

The PVC pipe gives a more even and smooth application, and

doesn't soak up the glue like a paint roller would. Clean

up is easier, too. Just let the glue dry on the pipe, and

then chip it off. Now it's ready to be used again

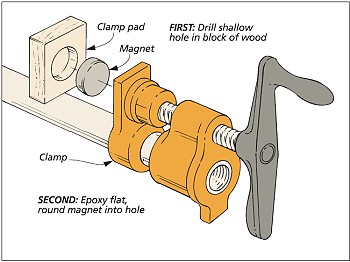

Magnetic Clamp

Pads

When using pipe clamps, use a block

of wood as a clamping pad. The clamping pad helps prevent

damage to the surface of your project when you tighten down

the joint. Problem is, it's always difficult to hold the

block in place while tightening the clamp.

To solve this problem, attach small magnets to your wood

blocks to keep them in place while you tighten the clamp. To

secure the magnet to the wood block, cut a recessed hole on

one side of the block (the same diameter as the magnet) and

then epoxy the magnet into the hole (see drawing). The magnet

holds the clamping pad in place, leaving you with both hands

free to align the clamp on the workpiece.

Pegboard

Clip

Cutting from a parts list? Making a note of things to pick up at the hardware store? This simple pegboard clip (shown at left) will keep the list from getting buried. Drill a hole through a clothes pin and glue in a short length of 1/4" dowel. Then insert the pin into a standard pegboard.

Division Made

Easy

Sometimes we need to draw lines on

a workpiece that divide it into equal-size parts. To do that

quickly and accurately, without a lot of mathematical

calculations, use this simple trick.

Let's say you want to divide a 2 ¾" wide

board into three equal parts. Start by hooking a tape measure

over one edge of the board (anywhere along its length). Then

angle the tape across the board until an increment

that’s easily divisible by three aligns with the

opposite edge of the board (3" in this case). Now mark

your board at the 1" and 2" points along the tape.

Your board is now divided into three equal parts.

Recent email:

Subject: Tiny Titan

Date: 29 August 2008

I raced the Tiny Titan (we called her "Saucy Shingle") in 1965. It is still my favorite boat of them all. I beat a lot factory hulls with it back in the 60's and still love her.

I raced AB hydro over 40 years ago and plan to build another one this winter to play with. Nice winter project.

Thanks again,

-- Edward W. King

Bathurst, New Brunswick, Canada

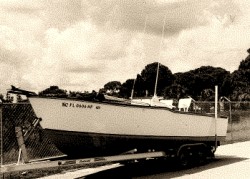

Subject: Double Eagle

Date: 29 August 2008

The boat performed admirably. I

built it in 3/16" aluminum and modified the gunwale with a

broken sheer. I grossly overpowered her with twin 90HP

outboards. My buddies nicknamed it the "drag boat" due

to almost violent acceleration from a start. Top speed was 41

mph.

The boat performed admirably. I

built it in 3/16" aluminum and modified the gunwale with a

broken sheer. I grossly overpowered her with twin 90HP

outboards. My buddies nicknamed it the "drag boat" due

to almost violent acceleration from a start. Top speed was 41

mph.I used the boat primarily offshore for 7 years and it is still in service locally. I hope you enjoy her picture.

Thanks,

-- Rick Huff

West Palm Beach, Florida

Subject: WebLetter

Date: 4 September 2008

Thank you for such a wonderful service you offer and also over the time I've received your WebLetter feel like a friendship has developed.

Summer is coming to a close up north in Pennsylvania but it still is possible to "keep the boat afloat". Wish I could be at the 2008 Gathering but responsibilities (like a job) prevent this.

Keep up the good work and I will look forward to your next WebLetter.

-- Robert Allison

Subject: Phatwater Kayak Race

Date: 9 September 2008

My name is Randy Griffin and I paddle a Glen-L 17-foot Sea Kayak. I am going to enter it in the 2008 Phatwater Kayak Challenge on the Mississippi River this coming October 11.

The Sea Kayak is an awesome boat, especially for down river in big water. CNN is going to cover the race and if my boat shows up in any footage you are welcome to use it as you see fit.

I am a late 50’s paddler so I do not expect to win but the Glen-L has done really good on local paddles of 30 miles at a time.

I hope to send you some business and I am going to put a product review on www.paddling.net. I have paddled many nice kayaks but none quite like the Glen-L Sea Kayak.

-- Randy Griffin

Huntsville, Alabama

the 2008 Gathering. We sure hope that YOU will be there too!

Subject: Deciding Which Boat to Build

Date: 4 September 2008

Thanks for letting me know that the plans are on the way. The most difficult thing about building a boat is deciding which boat to build.

I've searched far and wide on the internet for "Just the right boat" and many were considered. What made the choice even harder was the fact that I have a 1953 Evinrude 15hp Super Fastwin that my uncle bought brand new. This outboard was lightly used and in near new condition and I wanted a wooden boat to match the engine.

Your website provides more info than any other and I even bought your "Boat Building with Plywood" book a couple of years back as a study reference.

Well, here goes!

-- Steve Terpstra

Billings, Montana

Subject: A Wonderful Boat

Date: 26 September 2008

I still have it, and it has held up well, being over 12 years old. I used a standing lug rig, which I find a lot more handy than a Bermuda rig. All the spars stow in the boat.

Here is a shot of the boat being sailed by my eldest, Jim, and our dog, Toulouse, in Coos Bay, Oregon.

Best Regards,

-- Andy Suhrer

Coos Bay, Oregon

Subject: "Awesome" Tunnel Mite

Date: 23 September 2008

We live in Ontario and keep the boat on an island near Parry Sound on Georgian Bay, so we're subject to Canada's new 'Pleasure Craft Operator Card' boating regulations. These stipulate a written test to acquire the mandatory license required to operate a boat in Ontario, same requirements for kids and adults. The rules specify that up to age 12, kids can operate a boat with a 9.9 hp motor on their own, from 12 years up to 15 with a 40 hp, and from 16 on any horsepower motor. That meant my 10 year old son -- once he passed the test -- would be operating the Tunnel Mite with a 9.9 for a couple of years, but it's not a bad thing to keep the speed down a little at first [30+ kmph still achievable, though!]

While the merits of operator cards are debatable, the positive aspect was that my son was very keen to drive the Tunnel Mite on his own, so he was highly motivated to study, and ended up learning quite a bit of useful stuff on boating regulations, 'rules of the road,' navigation and safety. In time we may upgrade to a 25 hp motor which, judging from others' experiences, might get us closer to 60 kmph. At that point we'll probably go the added step of installing a remote throttle, but for now we've kept things simple and just use the 9.9's tiller [with a short extension] to control speed. Not a big issue -- once underway it is usually "full speed ahead"!

Our cottage has a sand beach, so we bought a light weight dolly from Seitech to facilitate hauling in/out. Seitech was very cooperative and modified an existing dolly to accommodate the Tunnel Mite's dimensions. We added a reinforcing crossbar at the back to better support the boat's weight, and used the largest size tires. Very easy now to pull the Tunnel Mite by hand out of the water and up the beach.

We've ended up with a very special boat, built by my dad for

his grandson, that we will treasure and enjoy for a long time.

Even the guys at our local marina said it was refreshing to see

a home-made boat that has some personal meaning, as opposed to

yet another store-bought jet ski.

We've ended up with a very special boat, built by my dad for

his grandson, that we will treasure and enjoy for a long time.

Even the guys at our local marina said it was refreshing to see

a home-made boat that has some personal meaning, as opposed to

yet another store-bought jet ski.And in my son's words, our Tunnel Mite is simply "awesome!"

-- Tom Schnull

Mississauga, Ontario, Canada

Cartoon of the Month

GLEN-L boats, of course