An Occasional Publication for the Home Boat Builder

Glen-L Marine Designs - 9152 Rosecrans Ave. - Bellflower, CA 90706

In this issue

In this issue

- Featured Design: Missile

- Feedback: Missile restored by Nate Brown

- Designer's Notebook: Evolution of the V-drive hull

- Chine junction: Different thickness of side and bottom planking

- What glue should I use?

- Feedback: Rampage by Frank

- Darla's Corner

- What propeller?

- Shop Talk: Turning the hull by Jim Pesci, Doug Hodder

- Feedback: Vee Gull built in aluminum by Ron Hounsell

- Feedback: Squirt - Movable jig by Bill and Linda Whitney

- Recent email

GLEN-L Update

- Web site:

- It's a new year and based on recent email, it looks like there are a lot of new boatbuilding projects starting in 2004. I hope you will all share what you learn with other builders via the Project Registry and Boatbuilder Connection. The problems you solve will soon be encountered by others... your feedback really helps your fellow boatbuilders. Anyone who would like to write an article about "Building the ____", I'm sure we can find a place for it in the WebLetter.

- This month we are featuring the Missile, classic V-drive ski/speed boat. Next month we will feature the V-Dory. I would appreciate any feedback, photos, stories, etc. re. the V-Dory. Anything that you would care to share with your fellow builders.

Editor

Featured design: Missile

The Missile was chosen for this month's feature because of an email from Shelby Scott, which came with photos of a Missile that his father intends to restore... (see Recent Email)

The Missile was designed in 1958 and was one of our most popular designs throughout the 1960's. The Missile was Glen's second V-drive design (the Hot Rod was first). The V-Drive installation shifted the motor aft, allowing increased speeds. Through the 1960's, builders put larger and larger motors in the Missile. Glen was not happy with big block engines in a 16' boat and designed several more SK-types in larger sizes for big block engines. The Thunderbolt and Tornado were both raced at over 100 mph using big block engines.

Rudy Mandella was one of the first builders to offer V-drive boats to the public. Rudy heard that Glen had plans available for a V-drive hull and assumed Glen had copied his hull and was upset. Glen heard about this and took the plans over to show him and Rudy agreed that the design was different from his. Glen and Rudy became friends. "Rudy was an eccentric guy... died of a heart attack while testing one of his boats."

For more about the Missile:

- Design page

- See the Old Boat Club for builder contacts.

- WebLetter 4

- Don Ruffa building the Missile test model

- From the Plans...

- Photos of Early Missiles...

Feedback: Missile restored

by Nate Brown

I just finished restoring an old Missile. I was

going to send you some shots of it after it got pin striped and lettered. Here

are some shots of "Breezy" as it is now. Great boat! I need to do

some adjustments to the rear plate because at about 70 it wants to  chine to port. FYI, I am building

a Squirt and plan to deck it like the Missile and paint it just like this one.

It is about a foot longer than the plan and is powered by a 650 Jet Ski engine.

It's almost skinned and I hope to finish it soon. I want to get a shot of

both boats in the water at the same time.

chine to port. FYI, I am building

a Squirt and plan to deck it like the Missile and paint it just like this one.

It is about a foot longer than the plan and is powered by a 650 Jet Ski engine.

It's almost skinned and I hope to finish it soon. I want to get a shot of

both boats in the water at the same time.

The engine is a 1962 Chevy 348 with a tri- power set up that I got off ebay; my brother put it all together for me. The original motor was a 409 but the previous owner sold the motor and then sold me the boat cheap. The boat needed a ton of work but it was worth it. First I rolled it over and dialed in the bottom then I stripped the deck and put on a new one and stained it with a water based stain. I then used West system with the UV hardener over the stain. The red, white, blue, and clear is Sikkins. Notice that I used a large round over bit and routed the sheer so it would look "Slipperier" I glassed the hull and faired it all in. I sanded forever and coated the inside with a polyurethane varnish. The v-drive is a Casale and I have no idea what gears are in it. I can be at the boat launch with new boats all around me and the boat that gets the attention is this one. I love classics and speed so this boat fits the bill just great.

The last shot is me during a race last year... my summer job is racing Unlimited hydros.

Note: The original builder of the boat was Ben Vanderkooi. ...NB

Designer's Notebook: The V-Drive evolution..circa 1953 to ?

The MISSILE, featured in this WebLetter, was created as part of an evolution in fast small boat design. The following facts are, as we remember them. Documented information (at least to our knowledge) is not available. In the early fifties, WWII was behind us and with the availability of higher horsepower motors, the interest in fast boats heightened. In Southern California, going fast meant being able to go faster than the next guy. This phenomenon was similar to the interest in street "hot rod" cars of the era. Develop something that will "wup" the competition was the word; cars or boats. However, the typical fast inboard runabout of that era was an in-line inboard motor, centrally located in a finely finished mahogany planked hull. Top speed was in the 40-50 MPH bracket. The faster these boats were pushed, the more the bow dropped and, combined with the deep forefoot common to runabouts of the era, became dangerous. The more powerful motors were being reworked to put out even more horses. Obviously, something had to be done to the hulls. It was learned that shifting the major weight (motor) aft, eliminating the deep forefoot, and making the aft sections virtually flat, made the hulls capable of more speed without the dangerous handling caused by the deep forefoot. Who developed this change? It's virtually impossible to know for sure. The old boating adage "nothing is new in boating" applies here. In our area, and to our knowledge, the boat type was primarily popular in the So Cal area first and the credit goes to Joe Mandella, a builder of finely crafted mahogany runabouts. Joe had a young client who was a real speed nut (name omitted to protect the guilty), who had graduated from the street rod group. His father evidently felt that fast boating was safer than street dragging. Probably the speeding tickets incurred from street racing also helped to get his monetary support. Anyway, Pop bankrolled several boats built by Joe, each that would hopefully be faster than the last. Joe, the fine craftsman, was up to the task and produced quite a few hulls that were powered with inboard stern mounted motors, connected to a v-drive; the stern drive was not commonly available. He switched from planked hulls to sheet plywood planking both for lightweight and structural integrity. The boats sold, after all, the competition "rodders" wanted to go faster too. And of course, this spawned other innovative boatbuilders (copy cats?). GLEN-L had a history of messing around with fast runabouts, so using the new innovations and incorporating some of our own, we designed the 16' 6" HOT ROD inboard with stern mounted motor connected to a v-drive. Plans had not previously been available for this type of craft so the response was instantaneous. The HOT ROD also started many individuals in the boatbuilding business; copies of the HOT ROD appeared under several company names. Some had subtle modifications; most were blatant copies, "designed" by the builder. GLEN-L has probably designed more of these craft than any other designer. TORNADO, 18'6", THUNDERBOLT, 17'3", DRAGSTER, 18' 4", RAMPAGE 18', and RENEGADE, 20'8" are all of this type. As an amusing aside: we heard of a builder who was producing a boat that looked very much like our HOT ROD design. Visiting the shop (our company affiliation not known to the builder) we were surprised to see our HOT ROD plan displayed on the wall with all identifying information cut away. When told that it looked like a GLEN-L design, the builder explained they were his drawings and that GLEN-L had copied the HOT ROD from him. Again name omitted to protect the guilty. We were also told that Joe Mandella felt that we had duplicated his boat and that he "was going to club us over the head with a 2" x 4" if he ever saw us". However, a visit with Joe, showing him our plans assured him our design, although of the same type, was not a copy. As this type of boat progressed, the terminology of SK or flat bottom was used. The initial boat hulls were plywood with similar features, flat or almost flat bottom at the transom, minimal vee forward, and tumblehome at the transom. The decks and cowl became the crowning feature. Plywood with exotic veneers such as all types of mahogany, walnut, monkey pod, zebra wood, or anything else that no other builder used, were common. All was fiberglassed, most by professionals that did only decks for the builders. And the upholstery; not just plain old flat cushions, but beautiful tuck and roll with heavily padded cockpit perimeters. Top this off with a polished, finned, accessory equipped, exposed motor (it would be sacrilege to try to conceal it), add a custom trailer with chrome accessories and you had a package everyone could appreciate. Fiberglass hulls eventually replaced those production hulls built of plywood, but for several years the fine crafted wood deck was still used. The MISSILE followed the HOT ROD and was specifically designed to accommodate the popular small block Chevy V8 motor. The 265-283 cu. in. motor has since grown in cubic inches and horsepower. The MISSILE at a 16' length was shorter than was typical. People always seem to want small go-fast boats and the MISSILE filled the bill. The original was clocked at just under 70 mph powered with a small block that had been hopped up a little, ignition, cam, carburetors etc. At top speed the boat, in our opinion, was a little too loose and we felt keeping it well under that figure would be desirable. However, the public paid no heed and large motors pushed the boat even faster. The MISSILE was a popular boat, featured on the cover of our current catalog of that era and reviewed in several national magazines. But, speeds in excess of what we had planned, led us to discontinue it. We had neither reports of structural failures nor high speed accidents, BUT, we felt there was a high potential. After we went on the Internet, we received many reports of builders and owners of the MISSILE. All highly complimentary, some being rebuilt, most quite old. And, most complaining that it was no longer listed in our Internet catalog. So, by popular demand, back it came. Yes we still feel the same; keep the speed reasonable and it's a fine boat. But then, what do we know? |

Chine junction: Different thickness of side and bottom planking

Question: I am building a Stiletto and would like to know about fairing, if any, of the spray rail. When the rail is installed, the bottom edge is not on the same plane as the hull planking, should it be? Or should it be left to cut spray?

Answer: First, a spray rail might provide some advantages, but it is not normally used on a boat of this type... it doesn't look cool.

If you use one, the hull would be fiberglassed, then the spray rail fastened to the side planking, resting against the edge of the bottom planking, any gaps filled with thickened Poxy-Shield. The purpose of a spray rail, in addition to hiding this joint, is to deflect spray; it is not faired.

For some other options see Plate 19E from BOATBUILDING WITH PLYWOOD.

What glue should I use?

This is a question we get every day. Although resorcinol and urea-formaldahyde (plastic resin) are used, today almost everyone uses epoxy. The question above most often really means, which of your epoxies should I use?

We offer two different boatbuilder epoxies:

Poxy-Grip (1:1) and Poxy-Shield (5:1).

Poxy-Grip is "easier" to mix (1:1) and requires no additives.

At low temperatures, it is difficult to mix (like mixing taffy) and is not as

thixotropic (non-runny) as thickened Poxy-Shield.

Poxy-Shield is a 5:1 mix. For most gluing applications, it requires a

filler; our filler of choice is #1 Silica.

The option that Allyn uses in the shop is Poxy-Shield with #1 Silica Filler added. If you were to use both types, you would probably choose Poxy-Shield because of the "workability". It is more expensive than Poxy-Grip because of the filler and although less expensive fillers can be used, they are not as nice to work with.

The explanation above is repeated often, but I usually end by saying that I would use Poxy-Shield with #1 Silica Filler.

For more information about Poxy-Shield and Fillers see the Epoxy section on our web site.

Feedback: Rampageby FrankMy project started in February of 2003 in my back yard, to the tune of a plastic covered, wooden, 20'x 30', make-shift shed and now, just recently, I made my final adjustments to my carb. Now! I'm ready for the water ...only problem is, it's 50 degrees and we are still officially in autumn. I guess I'll have to either trek down south for my second and final test run or park it until spring.

I started this "crazy" idea with two used circular saws (1.5 really!), a used $7, 3/8 inch corded drill and a fantastic vision of shooting down Rend Lake in Southern Illinois on my very own 50 ft Hustler! But after I found myself standing in my $150 shed, looking at this finished and pretty-well-faired frame, I began to shake off all of the strange looks and sarcastic pats-on-the-back. I thought to myself, "... maybe it ain't so crazy after all!", and I went on to purchase a few cordless tools and a leather tool belt (you know! ...the good stuff!). Well, to keep it short and sweet; here it is my 50 ft Hustler!

This is an 18 ft Rampage, "BLURRED", with a Jacuzzi Jet and (get this!) an OPEN BOW SEAT! It has a slightly modified '82 Vette small block (about 370 horses) with all MSD, Stainless Steel Bassett over-transom headers, a 750 Holley w/chrome bowls, Optima Blue battery with a chrome Teague Marine battery box, a chrome and white leather Dino Racing wheel, and a 400 watt CD system with an 8 inch sub. Thank you Glen for such easy to follow plans for the first-timers. Your plans allow the "have nots" to dream real dreams! And by the way, it IS for sale, I'm trying to get $$$ to finish my Bolero (halfmile@onemain.com or (618)734-1225, ask 4 Frank). |

Darla's corner

by Darla Schooler

I welcome your contributions

![]()

Trevor and daisy (from right to left) (c)

Manchester evening news Trevor and daisy (from right to left) (c)

Manchester evening news |

"Here's a link to a site that discusses

urban legends. This answer deals with the "duck quack echo"

issue.

http://www.snopes.com/critters/wild/duckecho.htm"

...Eric Williams

Eric was one of many who responded to my last column: Duck quack echo from Randy Williams.

The following sites also have information about the duck-quack issue... as if you needed more.

![]()

Quote of the month: "...suffice to say that growing old ain't for sissies". E.L. Anderson

From the Nov/Dec 2003 edition of Camping Life: 2004 State Trailer Laws

![]()

What Propeller?

A good place to find out what propeller to use for your boat: Michigan Wheel. When you get to the site, you will need to fill in a form in order to get a recommendation. Below is a copy of the answers I gave for the Gung Ho. I did not know hp and rpm for the 350n Chevy, so I did a search on the Internet and found the answer at this web site.

Shop Talk: Turning the hull

Geronimo - Turning the Hull

Jim Pesci, Sterling VA

I turned the hull last Saturday 12/06/04. I rounded up 6 guys to help, the whole thing took 2 hours. Most of the time was spent in logistics, removing an 8 ft section of the shadowbox fence, installing the tongue jack, adjusting the bunks, installing a keel roller on the back of the trailer, adjusting the winch stand, etc. I will change the bow roller to a 4 inch bow stop as the roller that was standard doesn't fit right.

Fortunately, it had just snowed 8 inches. This provided ample cushion for the hull when it was righted. Unfortunately, the temperature was 27 F which made working without gloves chilly. The actual turning took about 45 seconds with 2 guys on the transom, 2 on P&S and I was at the bow. The 2 guys on the down side didn't have to work that hard, but it was nice to have more than we needed. The building form was easily removed with a few careful strokes of a claw hammer. The keel roller was an indispensable item; with it, the hull moved effortlessly on. It works only during launch and load and is clear of the skeg by the time the bunks take the load. So far, the decision to buy the Venture VB-2000 trailer was a good one, I'm sure more adjustments will be needed come springtime. Future.... building the motor well, fore deck and windshield.

Malahini - Turning the Hull

Doug Hodder

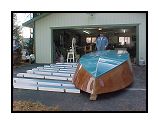

|

I turned the boat over today. I used 2"

Styrofoam sheets, cut 8" wide and 8'long. I taped them together into

4" thick "beams", spaced them out 18". It rolled over quite

easily and I lifted the ends while my neighbor pushed them stacked 4 high on

both ends. Once supported, the cradle slid under the boat easily. Total time

was only about 20 minutes, and no scratches on the bottom.  |

Vee Gull built in aluminum

Here's a picture of the Vee Gull I have just completed. It is all Aluminum with a 202 V6 working through a Volvo Penta leg. The hull is identical to the plans, but as you can see I've designed a cuddy cabin for it. I also moved the cabin forward 2ft to give more fishing room and more room to lay out our dive gear.

I was worried that the motor might be too small, but this proved not to be the case as we can cruise at 35 knots @ 3600 revs with 4 adults with gear aboard. It is extremely economical to run and only draws 2 ft at rest. I Have booked up about 70hrs running time off the weather coast on New Zealand's North Island without any major problems.

Ron Hounsell

Feedback: Squirt

You probably get a lot of pictures of upside-down boats. Well, here is another one. We started this Squirt about a year ago.

We made the building jig rigid, with lots of cross braces, so it can be moved, although I doubt if that's a good idea for a larger boat, unless the jig is welded steel. Notice the casters and leveling jacks. I had to plan for this to get the other boat out of the shop and back in. The jig will roll over an uneven driveway without flexing. Then it is placed exactly back in it's original spot and we count the turns on the jacks to insure original alignment. A level confirms that nothing changed. We only had to move it one time so far, but when we fiberglass the bottom it will be nice to do the sanding outdoors.

The Squirt was stretched to 11 feet. At that time I had not yet read in your website that you don't recommend stretching the stem. So I did lengthen the stem (at it's aft end) along with increasing the frame spacing. I am still not sure how to get a 10% longer boat if you don't lengthen the stem along with the frame spacing.

At that point the frames (all two of them) looked kind of far apart. Not being much of a boat guy, I didn't know if this mattered, but I felt better after adding extra laminations to the inside of all the keel, battens, chines and sheers. Then for good measure I added more corner blocks in various places like the stem-to-chine and sheer-to-transom joints.

Perhaps I should back up a bit. When I first saw all the great pictures on your web site, my initial reaction was that we should sell our nice fiberglass boat and build a Mist Miss with about 400 horsepower. Fortunately, my wife Linda has saved me from this sort of thing on numerous other occasions. This time she suggested that we keep the fiberglass boat and build a Squirt.

If you want to comment in the newsletter on these topics, feel free. And if you don't like what we have done, by all means tell the folks. We will let you know when the Squirt looks more like a boat, but it has taken a year to get this far.

Bill and Linda Whitney

Bothell, WA

Recent email:

Below is the result of your feedback form. It was submitted on Friday,

January 2, 2004

---------------------------------------------------------------------

name: Dan Reardon

Comments: Your web-site is awesome...thank you so much. I will finally build a boat because of you. If all goes well with that one...I will build many

Subject: Thank you

Date: Fri, 2 Jan 2004

I just had to say "thank you". I have been looking on the web for a weight conversion chart to give to my nursing students. I finally found one here and I am very happy.

I apologize for not having an interest in your products, but I do appreciate your service to our school!

Happy New Year and Have a good day!

Below is the result of your feedback form. It was submitted on Thursday,

January 1, 2004 at 09:56:38

------------------------------------------------------------------

name: capt fergus dearden

Comments: Glen L is one of my favorite web sites

Below is the result of your feedback form. It was submitted on Wednesday,

December 31, 2003 at 15:04:52

------------------------------------------------------------------

name: Phillip Potter

Comments: Best online boat plans catalog on the web... bar none!

Thanks for always answering my questions

Below is the result of your feedback form. It was submitted on Saturday,

December 27, 2003 at 02:10:20

--------------------------------------------------------------------

name: brad

Comments: I like your site and product. One thing that does bother me is that you continually have to move the page back and forth to read it. Why don't you put it on the site so we can read it by just scrolling down instead of left/right/left/right then down left/right/left/right. etc.

ANSWER: There are two ways to write the html to display a web page: exact

size or percentage.

i.e. width="90%" or width="500"

If you have to scroll, then your monitor is set at less than 800 x 600. This is

the most commonly used page size on the Internet and there will be many sites

you will have to scroll to see. You can go into your settings and change the

display to 800 x 600 to allow you to see sites on the web.

Note: The problem with using percentages (initially all of our pages used these) is that the placement of graphics and photos will vary with each computer. This sometimes makes the pages difficult to understand.

Thanks for your feedback.

--

Barry

Subject: eBay Glen L project

Date: Sat, 27 Dec 2003 23:18:36 -0800

Here is a hull that I am sure will be trashed after the hardware goes. Hate to see old boats die. If you have any loyal's on the East Coast you might drop them the link. Happy New Year!.

Nate

http://cgi.ebay.com/ebaymotors/ws/eBayISAPI.dll?ViewItem&category=26455& item=2450716096

Below is the result of your feedback form. It was submitted on Wednesday,

December 24, 2003 at 08:52:38

---------------------------------------------------------------------

name: Terry Cooper

Comments: Great site, first I have found with info on how to make a windshield. I am fixing up a 1960 Crosby left hand steer runabout and need to replace the windshield. Thanks for the helpful information. Found you via Google

Subject: Sea kayak II

Date: 22 Dec 2003

Have most of kayak assembled at this time. Need to epoxy deck on yet, and

then paint.

When I first started this project I had a lot of trouble finding marine plywood

and so I was talked into using other types of plywood, the first was 1/4 luan.

The pieces looked good until I started to twist the panels together and stitch,

at which time all the panels would snap and break.

The second try was exterior grade plywood. The pieces looked good again but

there were so many voids that when the panels were twisted into shape the

panels didn't line up right and the boats lines were way off.

I finely drove to Baltimore Maryland, 4 hours away to get the marine plywood

to finish the project. WOW, what a joy to work with this wood.

Note: The luan most likely had a very thick inner ply and paper thin outer plies. These can be found at most building supply stores, but are not structural panels, and not suited for boat construction. The test model was built with 1/4" Douglas-fir ABX (exterior) and we had no problem. But this plywood is not usually available at building supply stores. They usually carry lesser grades (AC or worse).

From: Scott, Shelby

Subject: Glen L Boat

Date: Wed, 17 Dec 2003

Hi,

My name is Shelby Scott. I have attached pictures of our boat that we inherited from my grandfather. His name was Melvin "Scottie" Scott and he and Walt Foley put it together in Eureka. He bought a 1959 Corvette engine in the crate and put it in. It was originally candy apple red and it had a 4 barrel carb on it. It did not go fast enough for Grandpa so he bored the engine out to a 301 and put a small cam in it and put Tri-Power on it and at that time he painted the boat again to the blue it is now. He built the trailer from scratch. My dad is now looking to restore the boat. I am searching for Christmas presents and I was wondering if there are any books you would recommend to help him with this restoration. My parents recently moved back to Eastern Oregon where he will have time to work on the boat more. Thank you for your help, I look forward to hearing back from you!!

Happy Holidays, Shelby Scott Bend, OR 97701

Note: Mr. Williams is the purchaser of the Amp Eater test model.

Date: Sun, 14 Dec 2003

Subject: Maiden voyage

Well, we finally got Amp Eater out in the water today, and I have to say the day was a great success. We took the GPS along and she did an honest 5MPH with two adults and a very happy 8-year-old. Felt like we were flying, considering the lack of noise and fuss. We slowed down to stealth speed and were able to cruise right by a great blue heron without even ruffling his feathers.

Congratulations to Glen for a wonderful design, and please tell Allyn thanks again for building a fine boat. The more I get to know her, the more evidence I see of his careful craftsmanship.

My wife says this is the perfect boat, and for us, and our style of boating, which is simply messing about in a pretty craft at civilized speeds, I have to agree.

Unfortunately, in all the excitement of "launch day", we forgot the camera. I do have this one of Allyn getting the boat ready to leave for her new home...

Happy Holidays to you all,

Best Regards,

Gary Williams

On Wed, 10 Dec 2003, Dominique SAVARIAU wrote:

Dear Sir,

I have started the construction of the Riviera and I must began my first report by a compliment. The way it is explained, presented, etc. is clear and confirms really that even a (French) novice like me can indeed understand what you are talking about. ...

Only one important question concerning the lumber size: Ref: page 10 of the Building the Glen Riviera "All widths are actual size" for me this means that when on the plan you are talking about 2" x 6" ; 2" can be reduced to 1 3/4" but the 6" (width) is the width that must appear on the boat (actual width). Luckily when we buy 2"x6" we are provided with +2/8 of an inch on width and thickness, so we buy 2 2/8" x 6 2/8".

The line below you mentioned as an example: "When 2"x4" are called out, these are to be standard size (2"x4" = 1 1/2" x 3 1/2")... then I don't understand any more, because in a 2"x4", 4" is the width and then there are not actual width in your example. So, please explain me what I have certainly missed.With compliments and my best regards

Dominique SAVARIAU

For certain applications (2"x4", 2"x6"), full widths are

not required. The reason has to do with the peculiar way that American lumber

is measured. Softwoods (such as Douglas-fir) are measured before milling, so

that a 2"x4" is actually 1 1/2" x 3 1/2". When designing

the boat, the designer takes this into account. These pieces are almost always

used for the motor stringers or set-up members. There would be nothing wrong

with using full width material, but in this case it is not necessary. Your

understanding of the instructions is very good indeed. We have much more

confusion from many people in this country who speak English as their first

language. In the case of all other members, widths ARE actual, as you describe

above.

I look forward to photos of your project.

--

Barry

Below is the result of your feedback form. It was submitted on Sunday,

January 4, 2004

--------------------------------------------------------------------

name: (Clarence) Gene Coffee

Comments: HI Glen-L Folks,

I am glad to see that you are still providing great boat plans for those of us

out here who like to sail in something we built. I ordered my Glen-L 13 frame

kit, plans and fastening kit way back in 1964. As I completed the boat I also

ordered your hardware and sail kits. I really appreciated the quality of all

your items. Now after almost forty years of sailing, my Glen-L 13 still draws

comments and praise at the ramp whenever I rig her for sail. Keep up the good

work.

Below is the result of your feedback form. It was submitted on Monday,

December 8, 2003

---------------------------------------------------------------------

name: Katie Allen

Comments: Eons ago, in the late 50's, I built one of your raised sheer 17 foot cruisers. I was well pleased with the boat and that's why I'm back.

Below is the result of your feedback form. It was submitted on Monday,

December 8, 2003 at 14:36:00

----------------------------------------------------------------------

name: Leif Simonsen

Comments: I plan to construct a houseboat and I'd like to start with your 'How-To' boating books. Years ago I built your Topper boat, which I've had a lot of fun with.

Build more boatsGLEN-L boats, of course