WebLetter 43

An Occasional Publication for the Home Boat Builder

Glen-L Marine Designs - 9152 Rosecrans Ave. - Bellflower, CA 90706

In this issue

- Now Available: Dragonfly flats boat

- Making a Molded Windshield by Greg Morrell

- On the Mark: Floorboards, storage and other interior design choices by Mark Bronkalla

- Inboard Hardware: Propeller Shafts

- From the US Coast Guard Site

- Shop Talk: Epoxy Applicators

- A few tips...

- Recent email

GLEN-L Update

- Web site:

- The Dragonfly flats boat is now available. The plans, Frame Kit, Stitch-N-Glue and Fiberglass Covering kits are on the shelf, waiting for your order. For more information see the article below.

- We have added several "Notes" pages in the Boat Design Catalog. These are accessed from the boat design page and are usually added in response to a question from a builder. The majority of designs do not yet have these pages, but we hope that eventually we will have them for all designs.

- More photos have been added to Customer Photos, in particular, those of Rob Sotirin's Pee Wee ought to inspire many builders. There is a link to photos of his boat in the Recent email section.

- Email... Starting in late November we noticed that we were getting more junk mail. By Christmas we were getting as many as 500+ messages on a Monday after the weekend. This morning, Thursday 29 January, we had 165 messages. After deleting the spam, we had a total of 10 real messages and Guestbook entries. Through the day, we received another 80 messages, most of which were spam. So why am I telling you this? We are using filters to try to cut down on spam and we are deleting much of what's left on the basis of the subject or sender. We do not expect anyone asking legitimate questions to use words like mortgage, Viagra, loans, teens or porn... but some people in a fit of humor might do so. Gayle adds that it is best to have a subject and not leave the subject area blank. Please, when corresponding, keep in mind that the subject is best kept to something relevant to boatbuilding.

- November through January is normally our slowest time of year. Contrary to what many think, people do not decide to build boats in the winter so they will have it ready for summer boating, skiing or fishing. Builders become "inspired" when they see their neighbor getting their boat ready, when the weather turns to sunshine and the trees to green. November through January is our time for inventory and cleaning and for enjoying the holidays with our families. We have also just begun serious work on implementing an on-line shopping cart. Based on past experience, I will not estimate when it will be ready. The shopping cart will integrate with our order processing system and will offer much more in the Boatbuilding Supplies section. As yet I have no idea how it will come together with our existing site, but hope that in the not too distant future, orders will be much easier to place on our site.

- Thanks to Mark Bronkalla, Greg Morrell, Uncle Don, Bob A, and all the others who contributed to this WebLetter.

Barry Witt

Editor

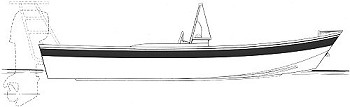

Dragonfly, a flats boat: Plans now available

Whether fishing for redfish off the coast of Texas or the coastal waters of Florida, or for bass in the backwaters of a local lake, the 17' 6" Dragonfly is the boat you have been waiting for. With sheer-level decks around a central cockpit and console, there is plenty of room to stand and cast. The Dragonfly may not be fancy, but it suits its purpose well.

The Dragonfly uses the popular stitch and glue boatbuilding method to make a lightweight, easily trailerable boat for the avid fisherman. To make construction even easier, we are offering a Frame Kit in addition to our Stitch-N-Glue Kit and Fiberglass Covering Kit. For more information on this latest addition to the Glen-L design Catalog see Dragonfly in the Outboards section of our on-line Boat Design Catalog.

Making a Molded Windshield

by Greg Morrell

The following pictorial shows how I made the windshield for my Ski Tow...

On the Mark: Floorboards, storage and other interior design choices

by Mark Bronkalla

The Riviera as called out in the plans has a very simple interior. This provides many opportunities for creativity on the part of the builder.

The first step is to look over the Riviera / Monaco photos on the Glen-L web site as well as classic boat books. The second step is to assess how the boat will be used. Optimizing for cruising versus water sports will often lead to different interior layouts.

Based on this information, you can make the first stylistic call. The fundamental decision is whether you are going with:

- The "Open Wood Look" interior, as I did

- "Finished Wood Look" - similar to older Chris Crafts

- "Modern Padded Leather / Vinyl Look" - as Bill Yonescu did

- "Riva / European" Look - as Martin Tomunak did

Each one has its own set of tradeoffs in style, where the effort is expended, and cost. For example, with any of the "finished" interior types little effort is required to be expended keeping the inside of the hull smooth and pretty when gluing up (other than for personal benefit) as it will be covered up. If you go with the open wood look, the interior of the hull IS the finished interior and every imperfection (in the cockpits at least) will show up.

Inboard Hardware: Propeller ShaftsFrom "Inboard Motor Installations". We hope this will provide enough information to make an informed selection from the prop shafts we offer in our Inboard Hardware section. On a propeller driven boat of the straight shaft or v-drive configuration, it is the propeller shaft that transmits the power of the engine to the propeller. To do the job smoothly and quietly, the propeller shaft must be straight and true. A bent shaft not only causes noise, but vibrations that could ruin shaft bearings, couplings, and create other problems down the transmission line. A propeller shaft must be strong enough to take the "twist" or torque of the motor and transfer it to the propeller. While many boat owners consider only the torsional strength of the propeller shaft, some thought must be given to bending and impact strength on boats where the shaft is exposed. In today's littered waters, shaft damage from colliding with submerged or floating objects is all too common. The size or diameter required for a propeller shaft depends on many variables, including the horsepower delivered through the shaft (called the "shaft horsepower", or SHP), the RPM of the propeller shaft, the propeller diameter, as well as the strength of the material to be used for the shaft. In the absence of any information other than propeller diameter, the propeller size as a general rule should not exceed about 14 times the diameter of the propeller shaft. This means that a 14" diameter propeller, for example, would use a 1" propeller shaft. A practical guide of shaft sizes for varying propellers may be obtained from the following chart. Note that no consideration has been given to the various materials that can be used for the shaft.

Another element to consider in shaft size is the support of the shaft along its length. A common installation in boats is for the shaft to be supported at the propeller and at the engine coupling with no more than one shaft diameter overhanging beyond the stern bearing (plus thread and taper). In this installation, which is considered as two rigid supports, a considerable length of shaft (sometimes exceeding 6') can be supported without an intermediate bearing. However, the placement of bearings depends on the shaft diameter, shaft speed, and strength of the material used for the shaft. While there are formulas and graphs that can be used to determine bearing spacing, a practical rule of thumb often advocated states that there should be bearings spaced not closer than about 20 times the shaft diameter, and no more than about 40 times the shaft apart. In other words, a 1" shaft should have an intermediate bearing if the distance between the engine flange and the strut or stern bearing is more than 40". This figure in practice, however, is frequently exceeded. In any case, if shaft whip occurs, an additional bearing should be installed. |

||||||||||||||||

From the US Coast Guard Site

The following was taken from the USCG web site. See more questions and answers on the USCG site.

Question

"Can I use a bigger motor on my boat than what

it's rated for?"

Answer

It is not a violation of Coast Guard regulations to

install or use an engine larger than specified on the capacity label, but there

may be state regulations prohibiting it, and restrictions from your own

insurance company regarding this.

There are no Coast Guard regulations against exceeding the safe loading capacity, however, there may be State regulations or restrictions from your insurance company which prohibit this. There is a Coast Guard regulation that gives Coast Guard Boarding Officers the power to terminate the use of a boat (send it back to shore) if, in the judgment of the Boarding Officer, the boat is overloaded. There is no fine for this, unless the operator refuses the Boarding Officer's order. We certainly hope that you will abide by the rating, as overloading may lead to capsizing or swamping of the boat.

NOTE: The Coast Guard Capacity Information label is required only on monohull boats less than 20' in length. The label is not required on multi-hull boats, pontoon boats (catamarans), or on any sailboats, canoes, kayaks, or inflatable boats, regardless of length.

Shop Talk: Epoxy Applicators

Not wishing to sound CHEAP, but rather Thrifty, I

thought to run this past you and the Crew.

After throwing away my 10,000th China Brush I had an idea strike me. Nice

handle... hum, I thought a little farther and this is the end result. The

2" China Brush Handle had a good feel to it so I thought to run it through

my Belt Sander and see what shapes I could come up with as an applicator for

Epoxy and fiberglass resins. The following shows a few of what I came up with.

You may share these with our Fellow Boat Builders who have a Thrifty

(Practical) use for the idea.

Be Well,

Uncle Don, beside the Kenai River...

A few tips...

Posted by Bob A on January 17, 2003 at 10:12:11: (Boatbuilder Connection)

In Reply to: Thanks for sharing posted by Barry on January 16, 2003 at 17:15:31:

Well... since you ask, I started building my first boat (Glen-L PowerYak) in July of 2000. I completed it (mostly) in the summer of 2002. I enjoyed the experience, and learned a lot in the process. I learned there will be frustrations and problems to solve, as with any new endeavor. I also learned to slow down and think about the problem and seek out information from others (i.e.. the Glen-L site, local boatbuilding supply shops, etc.). That connection with other builders has been one of the most enjoyable parts of the experience.

Here's a few tips I picked up along the way:

- Haven't got enough clamps for the sheer? Get some PVC pipe and slice with a handsaw into 1" to 1 1/2" pieces. Then make a cut in each each one. Presto, you have a huge number of clamps for very little money. I used 70 on the PowerYak sheers.

- Use a cabinet scraper (preferably one with a ball handle and another handle to apply pressure) to remove and level cured resin. Less dust, and a lot of control.

A word of warning, watch out, this boatbuilding can become addictive. I still have a few things to complete on the PowerYak, but have already started work on a 20' Huck Finn, and have also purchased the plans for the Dyno Mite that I will build with my son.

Thanks to all that shared their knowledge and experiences with me.

Recent email:

Below is the result of your feedback form. It was submitted on Thursday,

January 30, 2003 at 11:40:24

------------------------------------------------------------------------

name: Rennie Delceppo

Comments: I bought your Noyo Trawler plans back in 1987. Started to build the boat in 1990 and launched it in August 93. I retained the trawler hull but made some changes to the super structure. It is a super family boat and we have already enjoyed 9 years of sun, sea and safe journeys. Living on the Mediterranean island of Malta, the summer season lasts quite some time, giving us many months of the year to enjoy our boat. I will shortly be sending you some pictures by mail for you to put on the net.

Subject: Hunky Dory Builder

Date: 1-29-03

Dear Glen L,

I built a 22ft. Hunky Dory in 1982. It was the proudest day in my life when I

launched her. I also built a tandem trailer using your plans. After many trips

to Cabo San Lucas catching marlin, dorado tuna etc. she is still in great

shape. I also built a 14ft. driftboat from your plans.

Thank you

Tom

From the Boatbuilder Connection:

Posted by ken on January 28, 2003 at 18:14:52:

In Reply to: Red oak posted by Russ on January 28, 2003 at 12:51:14:

: Is red oak a suitable boat building material? I have seen reference to white

oak but not red.

Red oak rots out faster than white oak. Look at the end grain and you can see capillaries going up the length of the grain. These tend to hold moisture, actually wick up moisture, speeding the process of deterioration.

Subject: Amigo

Date: 1-23-03

Dear Glen-L, I am a first time builder. I have started constructing your Amigo design and I have found myself overwhelmed, confused, and scared. When I do have these feelings I study the plans more carefully, use common sense, and if all else fails I call you. When I do call, you don't treat me as a dope. You give me the answers I need and the know how to complete my dream. Thank you for being there when all others thought I was crazy.

Subject: Update project Pot Luck

Date: 1-23-03

Well, October 31 came and went, and we are still busy - finish work takes a

long time!. We have completed all major structures, the cabinetry of the cabin

is done, the outside surfaces are about one week away from being painted, the

engine is in the boat (Volvo KAMD300), we expect to launch the boat in early

March 2003. She is coming along very nicely, in the end the only things we

modified are the angle of the windshield to 45 degrees and we extended the

pilot house roof 2'. We have many progress pictures on our web page www.crdgroup.com/punta_bravo_33'.htm.

Anton Blok

Below is the result of your feedback form. It was submitted on Thursday,

January 23, 2003 at 11:23:42

----------------------------------------------------------------------

name: Kim Wheatley

Comments: I'm in the Coast Guard and currently oversee the inspections of

our small (<65') passenger vessel fleet in the Houston, TX area. Also, I

handle any new construction projects of small passenger vessels. Your website

has been extremely helpful and educational for me.

Subject: Reliant 49' by Jim Benge

Date: 1-23-03

There are some updated pictures of what little progress has been made on the

boat. The new pictures are on the home page and will be moved to the photos

page as new ones are added each month or so.

www.whitmar.org

Thanks,

Jim

Dec 23, 2002

Dear Glen-L:

Here are some pictures of your "Pee Wee" model that I built in 2000.

The boat has given me and my kids lots of great memories. The main modification

is a 3HP outboard motor that runs in a standing pipe through the keel -

it's a real "inboard outboard". I had fun covering the motor with

a "mock V8" complete with Quadrajet, chrome valve covers and pipes.

The motor's exhaust is ported out of the pipes, making for loud and

dramatic boating for the kids. The seats are from a Porsche 911 and the

throttle control is made from a 4-speed shifter from an old Cutlass that I

drove as a teenager. I plan on building a few more boats as the kids grow.

Thanks for the inspiration.

Regards,

Rob Sotirin

Mound MN

From the Boatbuilder Connection:

Posted by Ken on January 17, 2003 at 04:07:25:

Has anyone out there had experience with using finger joints? I am interested

in using finger joints on longitudinals. The finger joint cutters are available

from cabinet shops and run in a 1/2" collet router.

Posted by Mark Bronkalla on January 18, 2003 at 13:11:47:

In Reply to: Spliced longitudinals/finger joint posted by Ken on January 17,

19103 at 04:07:25:

I have used finger jointed stock for exterior house trim. I did not like it. The joints do not have the strength of a scarfed joint and the finger joints will have a significant discontinuity when bent. This will greatly slow the fairing process.

Try using my scarfing jig to make the joints. It is very easy and all you need is the simple jig and a table saw. A few others have also tried it with good reports.

Subject: Plywood boatbuilding

Date: 12-30-02

RUSH C. WINGATE wrote:

I have been looking at your designs, (which are wonderful by the way), and I do

have one question. I am told that building a boat out of plywood has a

disadvantage. Invariably, at some point you will hit something in the water,

crab pot buoy, something. I am told that if that plywood cracks and the wood

gets wet, it will not dry and will therefore, rot. A Fiberglass boat can be

easily repaired if that happens. So my question is this, For durability

purposes, is there an advantage in building in fiberglass, or is plywood

OK?

I would really appreciate your help as My father and I are seriously

considering a 30 foot motorboat, and want to make the right choice.

Answer:

This is not correct. You are obviously operating in saltwater. Saltwater will

not cause dry rot. If you hit something hard enough to crack the hull, you will

know it. Like a fiberglass hull, it should be repaired.

Dry rot can be a problem, but the culprit is fresh water in the hull, usually

rain. The inside of the hull should be well sealed and water should not be

allowed to stand in the hull. It is worth mentioning that most, if not all

fiberglass hulls, have longitudinal stiffeners that are wood. If the hull is

made with a chopper gun, the glass around the longitudinals is porous. If water

stands in the hull, the longitudinals may well get wet; they do not dry out,

and dry rot can occur. On any hull, maintenance is important. A 30' boat is

an investment that should be taken care of.

Barry

Answer 2:

A typical plywood boat has the best of both worlds. The fiberglass covering

adds the impact resistance and resistnce to cracking. The plywood and frame

have the better strength to weight ratio, compared to fiberglass. In the case

of damage, the composite wood fiberglass hull can easily be repaired. See my

article in Webletter 38 on

bottom repair.

Mark Bronkalla

Build more boats

GLEN-L boats, of course