WebLetter 52

An Occasional Publication for the Home Boat Builder

In this issue

- Featured Design: Audeen

- On the Mark: Spraying clear 2-part polyurethane by Mark Bronkalla

- Designer's Notebook: Cold-molded history

- Darla's Corner

- Legend of the Lake by Larry Grable

- Shop Talk

- Best of the board

- Recent email

GLEN-L Update

-

Web site:

-

This is a somewhat abbreviated WebLetter. We have had less feedback

than usual and much time was taken installing the new Boatbuilder

Connection. We have had a variety of reactions to the new board,

mostly favorable, but there have also been negative reactions...

"Why in the name of heaven did you change the boat builder

connection? IT WAS FINE THE WAY IT WAS!!!!!!!!!"

I was also skeptical about the new format. I do not have a lot of experience with other boards and really liked the old format. However, as I have become used to the new board, I can see a lot of advantages. It should be easier to find information about specific topics. As new messages are added, the string moves to the top of the list, making it easier to find the latest additions. I would suggest that if you start a new string, that you give it a title that will make it easier for others to find.

There have been comments about the fact that passwords are not "required". I wanted to keep the board as user friendly as possible, so do not intend to make the password mandatory unless the board is abused. I would suggest that if you intend to visit on a regular basis that you do register. This allows the program to display a list of posts since your visit and a few other features that are only operational if the program knows who you are.

If anyone has suggestions for new topic headings, I would be happy to add them. - Thanks for the feedback about the WebLetter. A few of the suggestions have been added to this WebLetter and more will be incorporated into future issues. The WebLetter is meant to be of help and to give encouragement to our builders, so your input is critical. If the weather has slowed your project, this might be a good time to write an article to share your experiences with your fellow builders.

- Another purpose of the WebLetter is, of course, to familiarize you with our products and to encourage you to buy them... it's what keeps us in business.

- As always we would like to thank all those who contributed to the WebLetter, especially Mark Bronkalla who is a regular contributor and who graciously shares his knowledge here and on the Boatbuilder Connection. Several other builders have indicated that they intend to write articles. They may feel that since so much time has passed since the offer to write, that we are no longer interested... not so. We always welcome your input.

-

This is a somewhat abbreviated WebLetter. We have had less feedback

than usual and much time was taken installing the new Boatbuilder

Connection. We have had a variety of reactions to the new board,

mostly favorable, but there have also been negative reactions...

"Why in the name of heaven did you change the boat builder

connection? IT WAS FINE THE WAY IT WAS!!!!!!!!!"

-

I do not know if we will post another letter

before Christmas and New Year, so all of us at Glen-L would like to take

this opportunity to wish you happy holidays. Slow down and enjoy your

family, be patient, and share the joy of the season.

...Glen, Allyn, Darla, Alfredo, Gayle, Barry

Editor

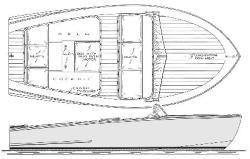

Featured design: Audeen

The Audeen was named in honor of Audry Green... a friend of Glen's at the time the boat was designed. The original test model was built by Warren Trombly behind a shop where he had a business building water skis. Warren also built the Sea Knight that was featured in five issues of Popular Mechanics magazine. At the time it was designed, we called her "modern". Today we call her a "classic".

Audeen, Mist Miss sister ships

The Audeen and Mist Miss were designed in 1955. Both designs were meant to evoke the feeling of the classic mahogany runabouts of earlier years, but incorporated a bottom shape that allowed them to take advantage of the larger automotive engines that were becoming available. The most common power source today is a small block Chevy.

The Mist Miss is a larger version of the Audeen and cannot be extended.

See the story of Larry Grable's Audeen in this WebLetter

Links:- Audeen design page

- Inboard hardware list

- Letter: WebLetter 46

- Audeen with jet: WebLetter 49

- Customer Photos

On the Mark: Spraying clear 2-part polyurethane

by Mark Bronkalla

The 2-part polyurethane finishes, also known as Linear Polyurethanes, have some very interesting characteristics. These characteristics are why they are so widely used in automotive applications, trucks and on airplanes. Positive points include:

- Inherent UV absorption due to the molecular structure of the linear (aliphatic) polyurethanes.

- Extremely hard finish.

- High, wet look gloss.

- Excellent buffing characteristics.

- Recoating windows of up to 3 days without sanding (see manufacturers directions for details).

Negative points include:

- Extreme toxicity. Forced air respirator, skin and eye protection are a MUST. There are NO approved cartridge respirators - the isocyanates are odorless.

- 10-25% chance of developing chemical induced asthma which is permanent from exposure to the isocyanate hardeners.

- Relatively high "buy-in cost". Need appropriate thinners, reducers, hardeners, forced air respirator and HVLP spray gun.

- Not for the casual user. These are designated as "professional use only" products. In some areas it may be hard to purchase as an amateur. Local dealer started to get worried with my questions. They are very concerned with safety and potential liability. Freely available, published info is sketchy. It took a bit of digging to find the links listed. The Dupont information is in a sign-in only area of their web site.

An excellent alternative to doing your own spraying, is to prep the boat and have a body shop spray on the finish.

Glen-L Gift Certificates

a great way to do your last minute gift shopping

Darla's corner

by Darla Schooler

I welcome your contributions

![]()

- A cat has 32 muscles in each ear.

- A shark is the only fish that can blink with both eyes.

- An ostrich's eye is bigger than its brain.

- A duck's quack doesn't echo, and no one knows why.*

* If you can think of a reason, please send it and I will post your answer in the next WebLetter.

![]()

The Legend of the Lake

by Larry Grable

Nineteen hundred and sixty was a good year to begin building a family ski boat for the families of Dean DuVal and Dwight Davis of Riverside California. Both men wanted quality and durability built into the boat for the "many ski trips to come". Little did they know, that their attention to craftsmanship and detail would lead to a boat that is still performing well over forty years later!

Construction began with the purchase of Glen-L Audeen plans and Frame Kit. State of the art fiberglass over wood was the construction of choice. Mahogany plywood was used for the top deck and transom for its inherent beauty. Providing the power, a Graymarine Fireball V-8, 327 cu. in., 238 HP, direct drive engine with a Warner Velvet Drive transmission. Many years later, Bennett hydraulic trim tabs would be added for stability and control.

The project took eighteen months to complete and included fabricating a custom trailer and even an addition to Dean's garage, complete with overhead rail hoist. Completion in 1962 was celebrated by a launching on Good Friday at Puddingstone Reservoir in San Dimas California (near Los Angeles).

Regular trips to the waters of Southern California proved her to be a reliable and strong hull and the drive system worked even better than expected. Family trips soon became ski trips for the guys. Four or five in a Buick Wildcat with boat in tow was a way of life for many years. Lake Havasu on the Colorado River was a favorite spot for weekend getaways. Other trips have taken the boat to lakes and rivers in Nevada, Arizona, Utah and, of course, to the Pacific Ocean.

It was on one of those Havasu trips in 1965 that I began my association with the Glen-L Audeen. My brother, Lee, worked with Dwight and became an inseparable ski buddy on every trip. Lee invited me and paid my way on one of the ski weekends and I soon became a regular.

By 1970, Dean had shown an interest in selling his part of the boat, so Dwight, Lee and myself became co-owners.

The next pivotal year was 1974 when a large section of fiberglass peeled from the bottom of the hull. I took on the task of repair and inverted the boat in my garage for the re-glassing. Working on the boat revealed to me the inherent strength and durability in the design and construction. Not only was assembly technique strong, but also the constant curves throughout add tremendous strength against the ever-changing forces of the water in storm conditions that are no stranger to our Audeen.

The work was progressing for re-launch in 1975 but was stopped with the tragic loss of my brother Don, in an industrial accident. Nineteen seventy-five became the only year in its long history the Audeen did not enter the water.

Work began again and the boat became wholly mine when Dwight moved on to other areas with his family and Lee bought another boat. The boat was back in the water the summer of 1976, our 200th anniversary as a nation.

I was now a married man with two small boys. These two little guys took their first rides in the boat before they were one year old. Officially now, the "family" boat was just that, the men's trips had ended. Countless families and friends, youth groups and college kids have gone boating and camping for the past 25 years with this Glen-L boat that began as a vision in 1960. These people have used every towable from skis to wake boards, tubes to torpedoes in crossing the waters behind the "Legend of the Lake".

The years of service, however, took their toll. The winter of 1989 was a time of renewal for paint and upholstery. In 1996 a complete engine rebuild, with updated electronic ignition was added, the final step for putting new life back into the "Legend". It's in condition now to carry it well into the 21st century.

The Audeen shape, the natural mahogany, and the excellent condition of a forty plus year old boat brings many people to stop, look, and listen as the engine roars to life. Of course, the boat is also an attraction on the trailer, I have told the story of its history in parking lots, rest areas, gas stations, etc.

And the story continues, my two sons have become masters at towing and operating "the boat", my grand children are just beginning to sit on my lap and steer the boat just as their fathers had done, nearly thirty years ago. It's truly a family boat that has bonded us and still brings us together for some of our best times.

Larry Grable, Mission Viejo, CA

Shop Talk

Barry,

I have heard from a few folks that built the TNT that like me had a

porpoising problem. Well, I set my cockpit a little farther back and had

the same problem so I fixed it by building a set of adjustable trim tabs.

I bought a 12" x 24" piece of stainless steel sheet (from MSC

Corp. @ about $18.00) and sheared it into shape. Then I bought a piano

hinge ($5.00) and a couple 1/2" bolts and coupling nuts ($3.00) and

assembled them as shown. They work great. Here is a picture.

Donald Slomke

TINY TITAN / Pat Larkin / Springfield, Pa /

started project: 8/03

hull completed: 11/03

I went with a Tele-Flex steering system and the stock OMC controls.

It's a Tele-Flex safe-t- with an 11' cable. I made 1 twist under

the dash and ran it out and back. When it's all finished it will be

clamped down and pretty. I experimented with routing it inside, but that

would have left a visible twist next to the motor... -Pat Larkin-

Best of the Board:

You already have the section at the end of each WebLetter that is "recent email", why not expand on this or open a section for the "best of the board". KenAnybody got good ideas for flotation/webletters? - ken 13:30:59 8/08/03 (10)

New Zip web site listed on the Boatbuilder Connection: http://members.home.nl/dawnz/diary.htm

Recent email:

Subject: Page correction

Date: Mon, 01 Dec 2003

> Just curious,

>

> I was wondering if this is a mistake. The Huck Finn page on your

website

> states that the 12' version can carry 1200lbs. and the 16'

version can

> only carry 1050lbs. This doesn't seem right since the pontoons

are the > same depth and width.

>

ANS:

Although these figures are approximations, dependent on the weight of

materials, they are essentially correct.

The ends of the 16' and larger are tapered and have less buoyancy.

They rise both fore and aft, so that when displacement is given at the

same waterline on all, the swim platform has more buoyancy for its size.

The longer platform on the 16' also adds weight/reduces capacity.

Capacity can be increased by using lighter materials in the hulls.

--

Barry

Subject: Sis

Date: Sat, 15 Nov 2003

Don't remember if this was sent to you before this but attached is a cute article someone at Carolyn's residence put together recently.

That's Carolyn in the center and don't know who the other ol' goats are... probably members of the "yacht club".

E. Anderson

Subject: Lofting

Date: Fri, 14 Nov 2003

Dear Mr. Witt,

Three months ago I decided to build a sailboat. This is a new

idea and challenge for me. I doubt you recall, but I asked your advice on

the type of boat that might be good for a novice builder and sailor. I

gave you 3 choices the Glen-L 17, the Glen-L 19 both of which I have

complete plans for and the Glen-L 13. In a very nice way you suggested

the 13 and I must say that after some musing, I can see your wisdom. Rest

assured that when I decide to embark on this project I shall be ordering

a set of plans. Sound advice is hard to come by and should be considered

when it is given. Thank you very much.

Now for the topic in the subject line.

Whenever I get involved in something new I try to assemble a

reference library on the topic. Over the past months I have been looking

at and purchasing various textbooks on boat building and sailmaking. I

have acquired four separate texts on boat building and have read selected

chapters in each. I am well versed in reading technical material

(medical) and have found the subject of lofting, although most critical

in the building of a boat, rather difficult to understand as it is

presented in 3 of the 4 books I now have. The book that has gotten it

across to me was copyrighted in 1962. The addition I have is the fifth

printing copyrighted in 1974 "Boat Building with Plywood" by

Glen L. Witt. I would guess this is either your father or grandfather.

At any rate, it is a first class work that has made a very complex topic

understandable and easy to apply and put into use in the real world. It

is well illustrated, has good photographs, and a writing style that flows

easily and covers the subject in a straight forward non-mystical

approach. I would recommend this text to anyone who is considering

building a boat. One cannot build what one does not understand. Your

families' contribution to shipwrighting is monumental in the

simplicity and quality of this work.

Most sincerely,

Gary K. Forshee

Below is the result of your feedback form. It was submitted on Friday,

November 14, 2003

------------------------------------------------------------------

name: Laurie Gillmer

Comments: I am currently enrolled in the Marine Tech program at Skagit

Valley College in Oak Harbor, WA. A fellow student told me of your

web-site and it has proved to be very helpful in supplementing class

materials. Lots of information I can access on the weekend when an

instructor is not available! Thanks!

Below is the result of your feedback form. It was submitted on Thursday,

November 13, 2003

------------------------------------------------------------------

name: Henning Nilsen

Comments: I built a 16 FT dory several years ago from your plans. The

plans were quite good and I had fun building the boat. It was a fun

project and a good change of pace from my hectic daily schedule, a good

way to relax.

Below is the result of your feedback form. It was submitted on Sunday,

November 2, 2003

----------------------------------------------------------------

name: CHRIS CARTER

Comments: Hi! back in the 1980's I had purchased a set of plans for

the little hunk dory. It took approx. 21 months to complete and I had a

great experience doing it. I also caught a lot of fish with it and did

exploring to Catalina Island, trailering to Punta Chuvata in Mexico, etc.

Someday I was thinking of building another boat. Thanks for the memories

when I saw your web site. Sincerely, Chris Carter

Subject: Zip

Date: 30 Oct 2003

Hey guys THANKS!!!! I really appreciate that you have upgraded the web

site and are featuring new boats in the model photos. I'm really

happy that both my boat and Mr. Pinske's made your upgrade on the Zip page. I

know how much time and effort went into mine and I'm sure that others

who are featured are also happy. It's sort of a validation that you

can build a boat and it looks good. I make an effort to get back to

anyone that e-mails me with any questions about the Zip and try to help

them out. Now my challenge is to get my Malahini finished and hopefully

it'll make the web page also. Thanks again. Doug Hodder

PS I'm looking at plans for my first cruiser.

![]()

![]()

![]()

![]()

![]()

We wish you the happiest of seasons

![]()

![]()

![]()

![]()

![]()